Benefits of Using Fully Automatic Negative Pressure Vacuum Sealing Machine for Food Cans

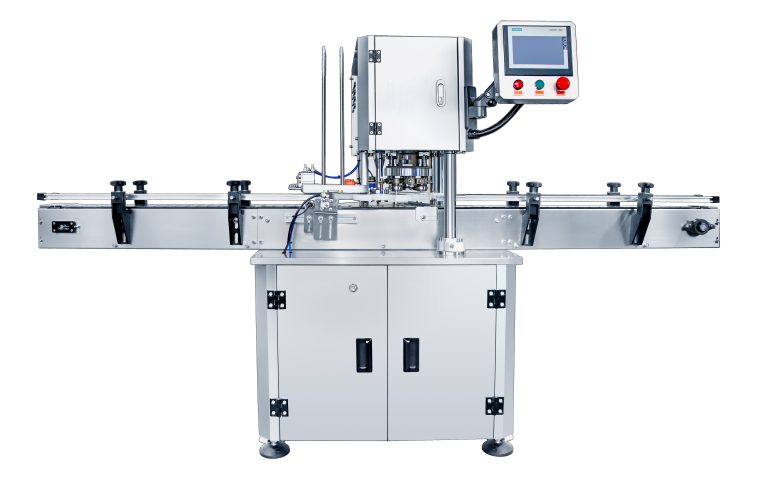

In the food industry, preserving the freshness and quality of products is essential to ensure customer satisfaction and safety. One of the most effective methods of preserving food is through vacuum sealing, which removes air from the packaging to prevent oxidation and spoilage. Fully automatic negative pressure vacuum sealing machines are a popular choice for food canning operations due to their efficiency and reliability.

One of the key benefits of using a fully automatic negative pressure vacuum sealing machine for food cans is the convenience it offers. These machines are designed to streamline the packaging process, allowing for quick and efficient sealing of food cans without the need for manual intervention. This not only saves time but also reduces the risk of human error, ensuring consistent and reliable results every time.

Another advantage of using a fully automatic negative pressure vacuum sealing machine is the level of precision it provides. These machines are equipped with advanced technology that allows for precise control over the sealing process, ensuring that the optimal vacuum level is achieved to preserve the freshness and quality of the food products. This level of precision is crucial in ensuring that the products meet the highest standards of quality and safety.

In addition to convenience and precision, fully automatic negative pressure vacuum sealing machines also offer cost savings for food canning operations. By automating the sealing process, these machines help to reduce labor costs and increase efficiency, allowing for higher production volumes with minimal resources. This not only improves the overall profitability of the operation but also ensures that the products are packaged in a timely manner to meet customer demand.

Furthermore, fully automatic negative pressure vacuum sealing machines are designed to be user-friendly, making them easy to operate and maintain. With intuitive controls and minimal training required, operators can quickly learn how to use these machines effectively, reducing the risk of downtime and ensuring continuous production. This ease of use also allows for greater flexibility in production scheduling, as operators can quickly switch between different products or packaging sizes without any hassle.

Overall, the benefits of using a fully automatic negative pressure vacuum sealing machine for food cans are clear. From convenience and precision to cost savings and ease of use, these machines offer a range of advantages that can help food canning operations improve their efficiency and productivity. By investing in a high-quality vacuum sealing machine, businesses can ensure that their products are packaged to the highest standards of quality and safety, ultimately leading to increased customer satisfaction and loyalty.