Table of Contents

Advantages of Using Automatic 8 Wheels Capping Machines for Packaging Efficiency

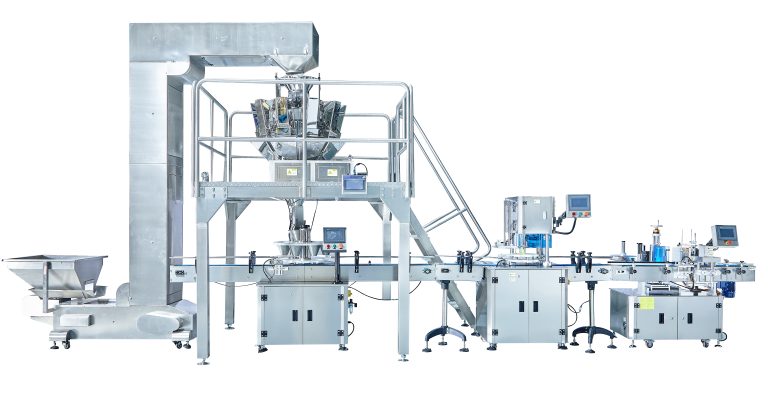

Packaging plays a crucial role in the success of any product. It not only protects the product during transportation and storage but also serves as a marketing tool to attract customers. In today’s fast-paced world, efficiency is key when it comes to packaging. One way to streamline the packaging process is by using automatic 8 wheels capping machines. These machines are designed to cap bottles quickly and accurately, saving time and labor costs. In this article, we will discuss the advantages of using automatic 8 wheels capping machines for packaging efficiency.

One of the main advantages of using automatic 8 wheels capping machines is their speed. These machines are capable of capping hundreds of bottles per minute, significantly reducing the time it takes to package a product. This increased speed allows companies to meet tight deadlines and fulfill orders quickly, ultimately improving customer satisfaction.

In addition to speed, automatic 8 wheels capping machines also offer a high level of accuracy. The machines are equipped with sensors and controls that ensure each bottle is capped correctly and securely. This eliminates the risk of leaks or spills, which can be costly and damaging to a company’s reputation. By using automatic 8 wheels capping machines, companies can ensure that their products are packaged correctly every time.

Another advantage of using automatic 8 wheels capping machines is their versatility. These machines can cap a wide range of bottle sizes and shapes, making them suitable for a variety of products. Whether you are packaging pharmaceuticals, cosmetics, or food and beverages, automatic 8 wheels capping machines can handle the job efficiently. This versatility allows companies to use the same machine for multiple products, saving space and reducing costs.

Furthermore, automatic 8 wheels capping machines are easy to operate and maintain. The machines are equipped with user-friendly interfaces that allow operators to set parameters and monitor the packaging process with ease. Additionally, automatic 8 wheels capping machines require minimal maintenance, reducing downtime and increasing productivity. This ease of use and maintenance makes automatic 8 wheels capping machines a cost-effective solution for companies looking to improve their packaging efficiency.

In conclusion, automatic 8 wheels capping machines offer a range of advantages for companies looking to streamline their packaging process. From increased speed and accuracy to versatility and ease of use, these machines are a valuable asset for any packaging operation. By investing in automatic 8 wheels capping machines, companies can improve their efficiency, reduce costs, and enhance the overall quality of their products. If you are looking to take your packaging to the next level, consider using automatic 8 wheels capping machines for a more efficient and effective packaging process.

Step-by-Step Guide on How to Operate Automatic 8 Wheels Capping Machines for Efficient Packaging

Automatic 8 wheels capping machines are a valuable tool for businesses looking to streamline their packaging process and increase efficiency. These machines are designed to cap bottles quickly and accurately, saving time and reducing the risk of errors. If you are considering investing in an automatic 8 wheels capping machine for your business, it is important to understand how to operate it effectively to maximize its benefits.

To begin using an automatic 8 wheels capping machine, the first step is to ensure that the machine is properly set up and calibrated. This includes adjusting the height of the capping heads to match the size of the bottles being capped, as well as setting the appropriate torque level for the caps. It is also important to make sure that the machine is clean and free of any debris that could interfere with its operation.

Once the machine is set up, the next step is to load the bottles onto the conveyor belt. It is important to space the bottles evenly to ensure that they are capped correctly. The bottles should be fed into the machine at a consistent rate to prevent jams and ensure smooth operation.

As the bottles move through the machine, the capping heads will automatically apply the caps to each bottle. The machine is equipped with sensors that detect when a bottle is in position and trigger the capping heads to apply the cap. The torque level of the capping heads can be adjusted to ensure that the caps are applied securely without damaging the bottle or the cap.

After the bottles have been capped, they will continue along the conveyor belt to the next stage of the packaging process. It is important to monitor the machine during operation to ensure that it is running smoothly and that all bottles are being capped correctly. If any issues arise, such as a jam or a misaligned bottle, it is important to stop the machine immediately and address the problem before resuming operation.

Once all of the bottles have been capped, the machine can be shut down and cleaned to prepare for the next batch of bottles. It is important to follow the manufacturer’s instructions for cleaning and maintenance to ensure that the machine continues to operate efficiently.

In conclusion, automatic 8 wheels capping machines are a valuable tool for businesses looking to increase efficiency in their packaging process. By following the steps outlined in this guide, you can effectively operate an automatic 8 wheels capping machine to streamline your packaging process and ensure that your products are capped accurately and securely. With proper setup, calibration, and monitoring, an automatic 8 wheels capping machine can help you save time and reduce the risk of errors in your packaging process.