The Automatic Paper Can Flanging and Cleaning Machine holds within it a set of intriguing secrets that contribute to its efficiency and effectiveness in the paper can manufacturing process. Let’s embark on a journey to uncover these hidden aspects.

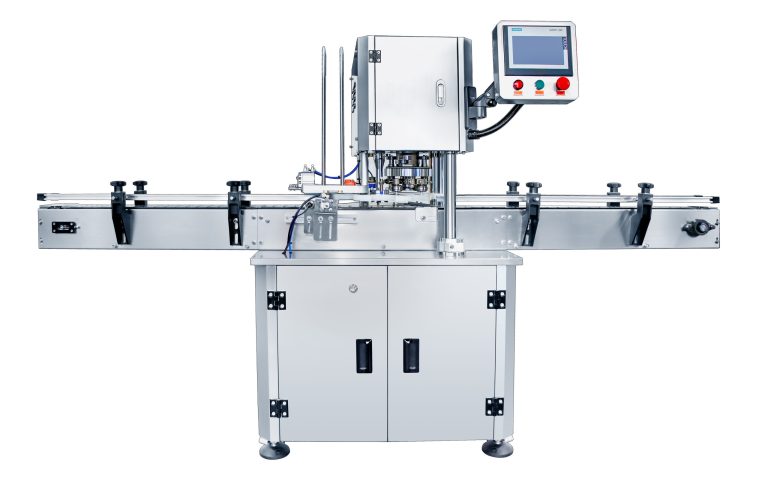

The first secret lies in its sophisticated mechanical design. The precise alignment of components and the optimized structure ensure smooth and seamless operations. The flanging mechanism is engineered to exert the perfect amount of force and pressure, creating flawless flanges on the paper cans every time.

The cleaning component of the machine holds its own mystery. Specialized nozzles and brushes are strategically placed to reach every nook and cranny of the paper can, ensuring a thorough and spotless clean. The type of cleaning agents used and the controlled application process are carefully calibrated for optimal results.

Another secret lies in the intelligent control system. This system not only regulates the speed and intensity of the flanging and cleaning processes but also constantly monitors the machine’s performance. It can detect any deviations or potential issues in real-time and make necessary adjustments to maintain high-quality output.

The materials chosen for the construction of the machine also play a crucial role. High-quality, durable materials that are resistant to wear and tear ensure the longevity and consistent performance of the Automatic Paper Can Flanging and Cleaning Machine.

The secret of its adaptability is yet another aspect worth exploring. The machine can be easily configured and reconfigured to handle different sizes and types of paper cans, making it highly versatile and suitable for various production requirements.

In conclusion, uncovering the secrets of the Automatic Paper Can Flanging and Cleaning Machine reveals a combination of advanced design, intelligent control, quality materials, and adaptability. These elements work in harmony to make this machine a valuable asset in the paper can industry.