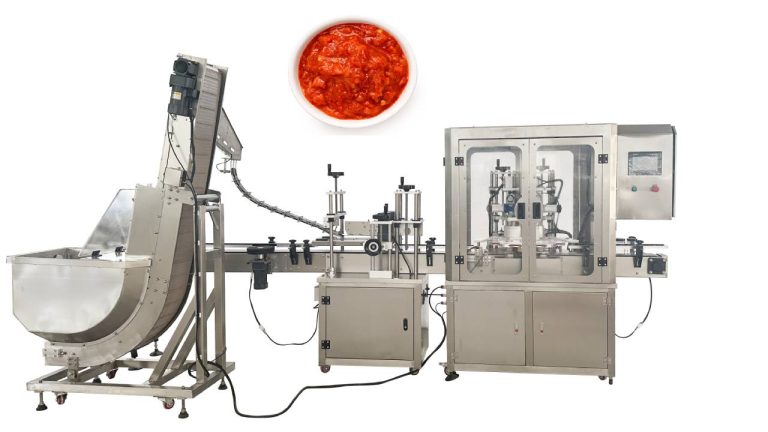

The High Quality Milk Powder Tin Can Filling Machine is a game-changer in the world of milk powder packaging. Let’s explore its exceptional features and the impact it has on the industry.

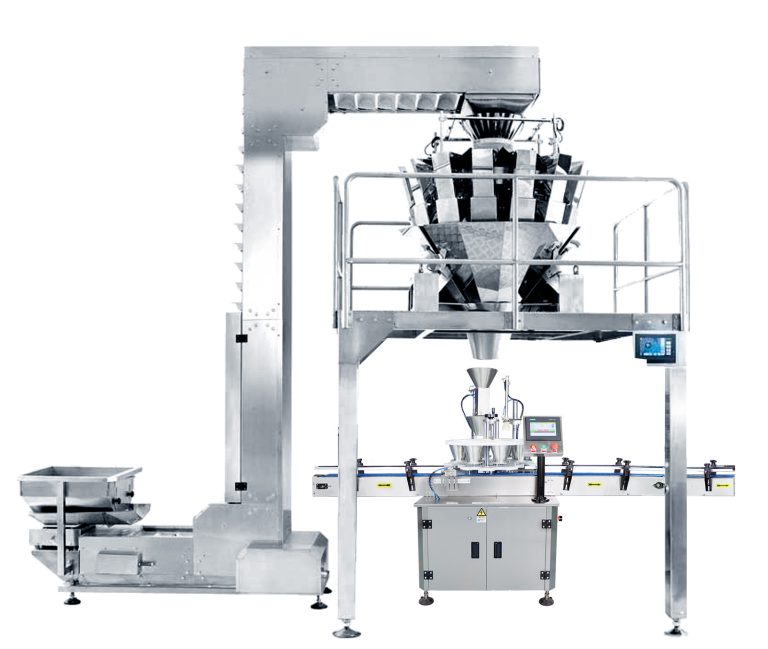

This state-of-the-art machine is meticulously designed to fill milk powder into tin cans with utmost precision and efficiency. The advanced filling mechanism ensures a consistent and accurate amount of milk powder in each can, maintaining the product’s quality and safety.

The automatic operation of the machine significantly reduces human intervention, minimizing the risk of errors and increasing productivity. It can handle large volumes of milk powder filling tasks in a short period of time.

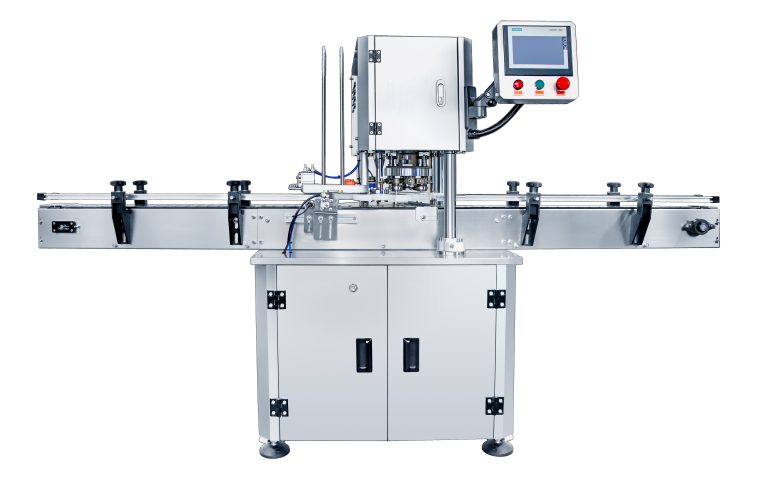

The machine is engineered to accommodate various tin can sizes and shapes, providing flexibility for different packaging requirements. It also incorporates advanced control systems that allow for easy customization of filling parameters based on specific product specifications.

The high-quality construction and materials used in the machine ensure its durability and long-term reliability, making it a valuable investment for milk powder manufacturers.

With its ability to deliver precise and hygienic filling, the High Quality Milk Powder Tin Can Filling Machine plays a crucial role in meeting the strict standards of the dairy industry.

In conclusion, it is a key component in ensuring the successful packaging and delivery of high-quality milk powder to consumers.