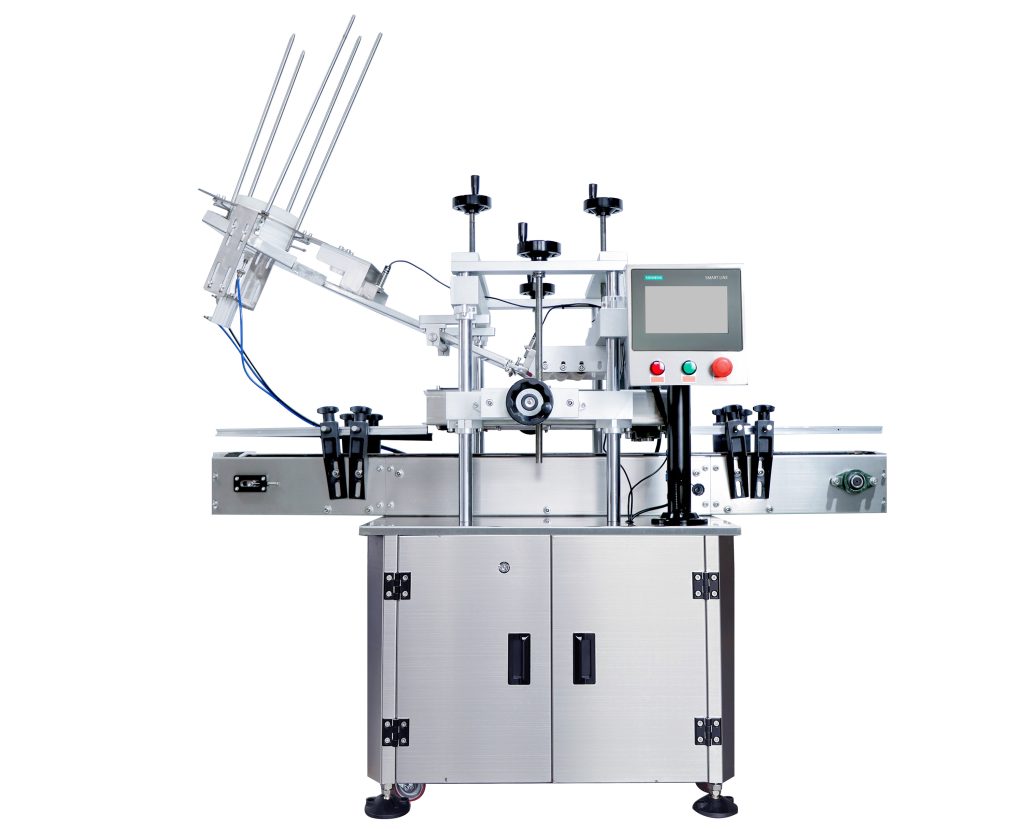

In the realm of powder can packaging, the dustproof cap press capping machine plays a crucial role in ensuring product integrity and presentation.

This specialized machine is designed to precisely apply dustproof caps onto powder cans, providing an effective barrier against dust, moisture, and other contaminants. The press capping mechanism ensures a secure and tight fit, safeguarding the powder inside from any potential spoilage or degradation.

One of the key advantages of this machine is its ability to maintain a clean and hygienic packaging environment. By effectively sealing the powder cans, it helps to preserve the quality and purity of the powder, which is especially important for products such as food, pharmaceuticals, or cosmetics.

The dustproof cap press capping machine is engineered for efficiency and speed. It can handle a large volume of powder cans in a short period, meeting the demands of high-production packaging lines. Its automated operation reduces the reliance on manual labor, minimizing the risk of human error and increasing overall productivity.

The machine is also highly customizable to accommodate different sizes and styles of powder cans and caps. This flexibility allows manufacturers to adapt to changing packaging requirements and product variations with ease.

In terms of quality control, the machine is equipped with sensors and monitoring systems to ensure that each cap is properly applied and the sealing is consistent. Any faulty cappings are detected and rejected, guaranteeing that only top-quality packaged products reach the market.

Maintenance of the dustproof cap press capping machine is relatively straightforward. Regular cleaning and inspection of key components help to prolong its lifespan and ensure its reliable performance over time.

Overall, the dustproof cap press capping machine is an essential tool for industries dealing with powder can packaging, offering a combination of protection, efficiency, and quality assurance.

Stay tuned to our blogs for more detailed insights and updates on the latest advancements in packaging machinery!

-768x512.jpg)