Table of Contents

Introduction

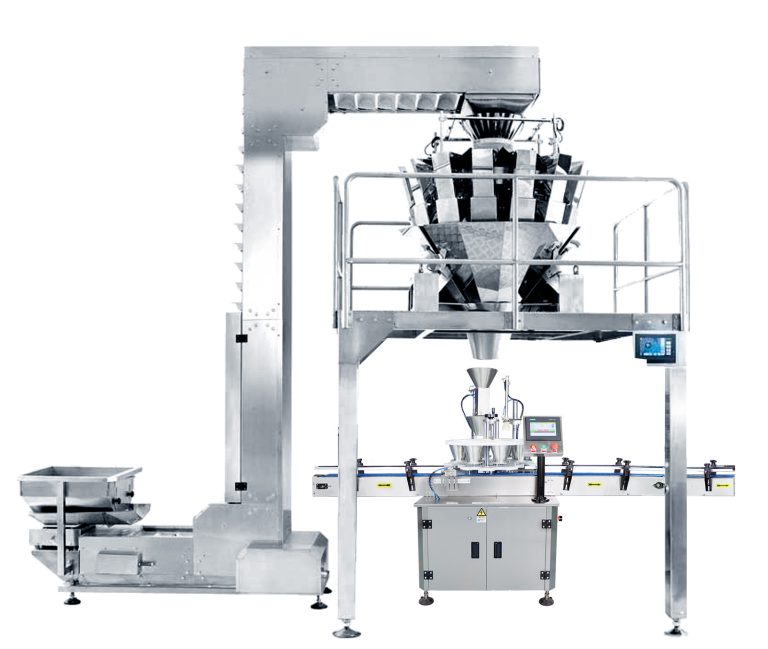

In the modern packaging industry, the semi – automatic vacuum nitrogen flushing seaming machine has become an indispensable piece of equipment. It plays a vital role in preserving the quality and extending the shelf – life of various products. Understanding how this machine operates and its significance can help businesses make informed decisions about their packaging processes.

How the Semi – Automatic Vacuum Nitrogen Flushing Seaming Machine Works

Loading the Container

The process begins with an operator manually placing the container, such as a can or a jar, onto the machine’s seaming station. This semi – automatic aspect allows for flexibility in handling different container sizes and shapes, making it suitable for small – to – medium – scale production.

Vacuuming

Once the container is in place, the machine initiates the vacuuming process. A powerful vacuum pump is connected to the container through a sealed system. The pump starts to remove the air inside the container, creating a low – pressure environment. This step is crucial because oxygen is a major factor in product spoilage. Oxidation can cause food to lose its flavor, color, and nutritional value. It can also lead to the growth of aerobic bacteria and mold. By removing oxygen, the machine helps to slow down these degradation processes.

Nitrogen Flushing

After the vacuuming is complete, nitrogen gas is introduced into the container. Nitrogen is an inert gas, which means it does not react with the product inside the container. The nitrogen flushing serves multiple purposes. Firstly, it displaces any remaining oxygen in the container, further reducing the risk of oxidation. Secondly, it creates a positive pressure inside the container, which helps to prevent the entry of external contaminants. The amount of nitrogen flushed into the container can be adjusted according to the specific requirements of the product.

Seaming

Once the container is filled with nitrogen, the seaming process begins. The machine uses a set of seaming rollers to tightly seal the lid onto the container. The seaming rollers apply precise pressure and motion to create a hermetic seal. A proper seal is essential to maintain the vacuum and nitrogen environment inside the container, ensuring that the product remains protected during storage and transportation.

Why the Semi – Automatic Vacuum Nitrogen Flushing Seaming Machine Matters

Extended Shelf – Life

One of the most significant benefits of using this machine is the extended shelf – life of the products. By removing oxygen and replacing it with nitrogen, the machine inhibits the growth of microorganisms and slows down chemical reactions that cause spoilage. For example, in the food industry, products such as coffee, nuts, and dried fruits can have their shelf – lives extended from a few weeks to several months or even years. This not only reduces waste but also allows businesses to distribute their products over a wider geographical area.

Preservation of Product Quality

The machine helps to preserve the quality of the products. In the case of food products, it maintains the flavor, aroma, and texture. For instance, nitrogen flushing can prevent the staling of baked goods and the rancidity of oils. In the pharmaceutical and cosmetic industries, it protects the active ingredients from degradation, ensuring that the products remain effective and safe for use.

Cost – Effectiveness

Compared to fully automatic machines, semi – automatic vacuum nitrogen flushing seaming machines are more cost – effective. They require a lower initial investment, making them accessible to small and medium – sized enterprises. Additionally, the semi – automatic operation allows for greater flexibility in production volume. Businesses can adjust the production rate according to their needs, which helps to optimize costs.

Environmental Friendliness

By extending the shelf – life of products, the machine reduces food waste. Food waste is a significant environmental issue, as it contributes to greenhouse gas emissions during decomposition. Using this machine can help businesses play a part in reducing their environmental impact.

Compliance with Industry Standards

In many industries, there are strict regulations regarding product packaging and preservation. The semi – automatic vacuum nitrogen flushing seaming machine helps businesses meet these standards. For example, in the food industry, it ensures that products are packaged in a way that maintains their safety and quality, which is essential for consumer health and regulatory compliance.

Conclusion

The semi – automatic vacuum nitrogen flushing seaming machine is a remarkable piece of technology that offers numerous benefits to businesses in various industries. Its ability to create a protective packaging environment through vacuuming, nitrogen flushing, and seaming helps to extend product shelf – life, preserve quality, and reduce costs. As the demand for high – quality, long – lasting products continues to grow, the importance of this machine will only increase.