Table of Contents

Benefits of Using Automatic Weigher Filling Equipment for Black Walnuts

Black walnuts are a popular nut known for their rich, earthy flavor and crunchy texture. They are often used in baking, cooking, and snacking, making them a versatile ingredient in many dishes. However, processing black walnuts can be a labor-intensive task, especially when it comes to weighing and filling them for packaging. This is where automatic weigher filling equipment comes in handy.

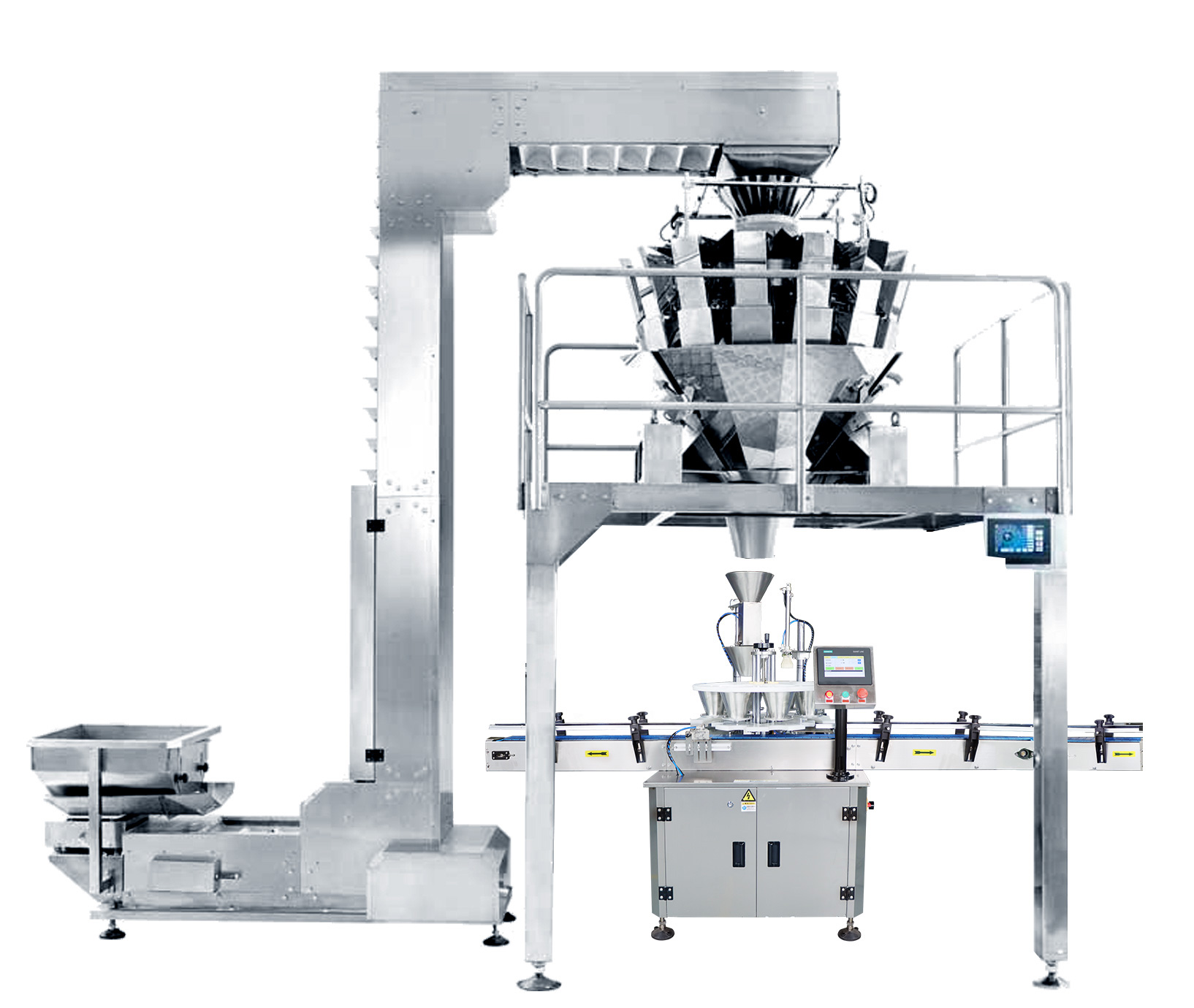

Automatic weigher filling equipment is a type of machinery that is designed to accurately weigh and fill products into containers or packaging. When it comes to black walnuts, this equipment can streamline the process of packaging these nuts, saving time and labor costs for businesses that deal with large quantities of black walnuts.

One of the key benefits of using automatic weigher filling equipment for black walnuts is its efficiency. This equipment is designed to weigh and fill products quickly and accurately, ensuring that each package contains the correct amount of black walnuts. This can help businesses increase their productivity and meet customer demand more effectively.

In addition to efficiency, automatic weigher filling equipment also offers precision. These machines are equipped with advanced technology that allows them to weigh products with a high degree of accuracy. This means that businesses can be confident that each package of black walnuts is filled to the correct weight, reducing the risk of underfilling or overfilling.

Another benefit of using automatic weigher filling equipment for black walnuts is consistency. By automating the weighing and filling process, businesses can ensure that each package of black walnuts is filled in the same way every time. This can help maintain the quality and consistency of the product, leading to increased customer satisfaction and loyalty.

Furthermore, automatic weigher filling equipment can help businesses reduce waste. By accurately weighing and filling products, businesses can minimize the amount of product that is wasted due to overfilling or underfilling. This can lead to cost savings for businesses and a more sustainable approach to packaging black walnuts.

Overall, automatic weigher filling equipment offers a range of benefits for businesses that deal with black walnuts. From increased efficiency and precision to consistency and reduced waste, this equipment can help businesses streamline their packaging process and improve their bottom line.

In conclusion, automatic weigher filling equipment is a valuable tool for businesses that process black walnuts. By investing in this equipment, businesses can increase their efficiency, accuracy, and consistency when packaging black walnuts. This can lead to cost savings, improved customer satisfaction, and a more sustainable approach to packaging.

How to Choose the Right Automatic Weigher Filling Equipment for Black Walnuts

When it comes to packaging black walnuts, having the right automatic weigher filling equipment is crucial. This equipment not only ensures accurate and efficient filling but also helps in maintaining the quality of the product. With so many options available in the market, choosing the right automatic weigher filling equipment can be a daunting task. In this article, we will discuss some key factors to consider when selecting automatic weigher filling equipment for black walnuts.

First and foremost, it is important to consider the capacity of the automatic weigher filling equipment. The capacity of the equipment should be able to meet the production demands of your business. It is essential to choose equipment that can handle the volume of black walnuts that need to be filled on a daily basis. Additionally, consider the speed at which the equipment can fill the bags or containers. A faster filling speed can help in increasing productivity and efficiency.

Another important factor to consider is the accuracy of the automatic weigher filling equipment. The equipment should be able to accurately measure and fill the desired quantity of black walnuts. This is crucial in ensuring consistency in the weight of each bag or container. Look for equipment that has a high level of accuracy to avoid any discrepancies in the weight of the product.

In addition to capacity and accuracy, it is also important to consider the ease of use of the automatic weigher filling equipment. The equipment should be user-friendly and easy to operate. Consider equipment that comes with a user manual or training materials to help operators understand how to use the equipment effectively. This can help in reducing downtime and increasing productivity.

Furthermore, consider the maintenance requirements of the automatic weigher filling equipment. Choose equipment that is easy to clean and maintain. Regular maintenance is essential to ensure the equipment functions properly and lasts for a long time. Look for equipment that is made from high-quality materials and is durable to withstand the rigors of daily use.

When selecting automatic weigher filling equipment for black walnuts, it is also important to consider the space available in your production facility. Choose equipment that fits within the available space and can be easily integrated into your existing production line. Consider the layout of your facility and how the equipment will be positioned to ensure smooth operation.

Lastly, consider the cost of the automatic weigher filling equipment. While it is important to invest in high-quality equipment, it is also essential to consider your budget. Compare prices from different manufacturers and suppliers to find equipment that offers the best value for money. Consider the long-term benefits of the equipment in terms of increased productivity and efficiency.

In conclusion, choosing the right automatic weigher filling equipment for black walnuts is essential for ensuring accurate and efficient packaging. Consider factors such as capacity, accuracy, ease of use, maintenance requirements, space availability, and cost when selecting equipment. By taking these factors into consideration, you can find the perfect automatic weigher filling equipment for your business.

-768x622.jpg)