Table of Contents

Benefits of Using Automatic Can Sealing Machine with Nitrogen Flush

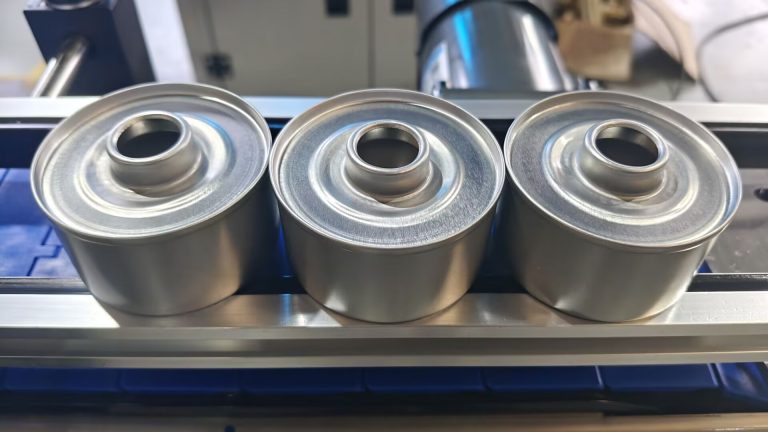

In the food and beverage industry, packaging plays a crucial role in ensuring the quality and safety of products. One of the key aspects of packaging is sealing, as it helps to preserve the freshness and flavor of the contents inside the container. When it comes to sealing metal cans, using an automatic can sealing machine with nitrogen flush can offer numerous benefits.

One of the main advantages of using an automatic can sealing machine with nitrogen flush is the ability to create a hermetic seal. This type of seal is airtight, preventing oxygen from entering the can and causing oxidation of the contents. By flushing the can with nitrogen before sealing, any remaining oxygen is displaced, further reducing the risk of spoilage. This can help to extend the shelf life of the product and maintain its quality for a longer period of time.

Another benefit of using an automatic can sealing machine with nitrogen flush is the ability to prevent microbial growth. Oxygen is a key factor in the growth of bacteria and other microorganisms that can spoil food products. By removing oxygen from the can and replacing it with nitrogen, the risk of contamination is significantly reduced. This can help to ensure the safety of the product and protect consumers from potential health risks.

In addition to preserving the quality and safety of the product, using an automatic can sealing machine with nitrogen flush can also improve the overall appearance of the packaging. A hermetically sealed can with a nitrogen flush creates a clean and professional look, which can enhance the perceived value of the product. This can be particularly important for brands looking to differentiate themselves in a competitive market and attract consumers with premium packaging.

Furthermore, using an automatic can sealing machine with nitrogen flush can also increase production efficiency. These machines are designed to seal cans quickly and accurately, reducing the need for manual labor and minimizing the risk of human error. This can help to streamline the packaging process and improve overall productivity, allowing manufacturers to meet demand more effectively and reduce costs associated with labor.

Overall, the benefits of using an automatic can sealing machine with nitrogen flush are clear. From preserving the quality and safety of the product to improving packaging aesthetics and increasing production efficiency, these machines offer a range of advantages for manufacturers in the food and beverage industry. By investing in this technology, companies can enhance their packaging capabilities and deliver high-quality products to consumers.

How to Choose the Right Automatic Can Sealing Machine for Metal Can with Nitrogen Flush

In the food and beverage industry, packaging plays a crucial role in ensuring the quality and safety of products. One popular method of packaging is using metal cans, which provide a durable and airtight container for a variety of products. To ensure the freshness and longevity of the contents inside the can, many manufacturers opt to use a nitrogen flush system during the sealing process. This involves replacing the air inside the can with nitrogen gas before sealing it, which helps to prevent oxidation and maintain product quality.

When it comes to sealing metal cans with a nitrogen flush, an automatic can sealing machine is the ideal choice for manufacturers looking to increase efficiency and consistency in their packaging process. These machines are designed to seal cans quickly and accurately, ensuring a tight seal that keeps the nitrogen gas inside the can. However, with so many options available on the market, choosing the right automatic can sealing machine for metal cans with a nitrogen flush can be a daunting task. Here are some factors to consider when making your selection.

First and foremost, it is important to consider the size and shape of the cans you will be sealing. Automatic can sealing machines come in a variety of sizes and configurations to accommodate different can sizes and shapes. Make sure to choose a machine that is compatible with the cans you will be using to ensure a proper seal every time.

Another important factor to consider is the speed and efficiency of the machine. Look for a machine that can seal cans quickly and accurately, without compromising on the quality of the seal. A machine with adjustable speed settings can be beneficial, as it allows you to adjust the sealing speed based on the specific requirements of your production line.

In addition to speed and compatibility, it is also important to consider the overall build quality and durability of the machine. Look for a machine that is made from high-quality materials and is built to withstand the rigors of continuous use in a production environment. A durable machine will not only last longer but will also require less maintenance and repair, saving you time and money in the long run.

Furthermore, consider the ease of use and maintenance of the machine. Look for a machine that is user-friendly and easy to operate, with intuitive controls and clear instructions. Additionally, choose a machine that is easy to clean and maintain, as regular maintenance is essential to ensure the longevity and efficiency of the machine.

Lastly, consider the reputation and customer reviews of the manufacturer. Look for a reputable manufacturer with a track record of producing high-quality automatic can sealing machines. Reading customer reviews and testimonials can provide valuable insights into the performance and reliability of the machine, helping you make an informed decision.

In conclusion, choosing the right automatic can sealing machine for metal cans with a nitrogen flush is essential for ensuring the quality and safety of your products. Consider factors such as can size compatibility, sealing speed, build quality, ease of use, and manufacturer reputation when making your selection. By taking the time to research and evaluate your options, you can find a machine that meets your specific requirements and helps streamline your packaging process.

-768x622.jpg)