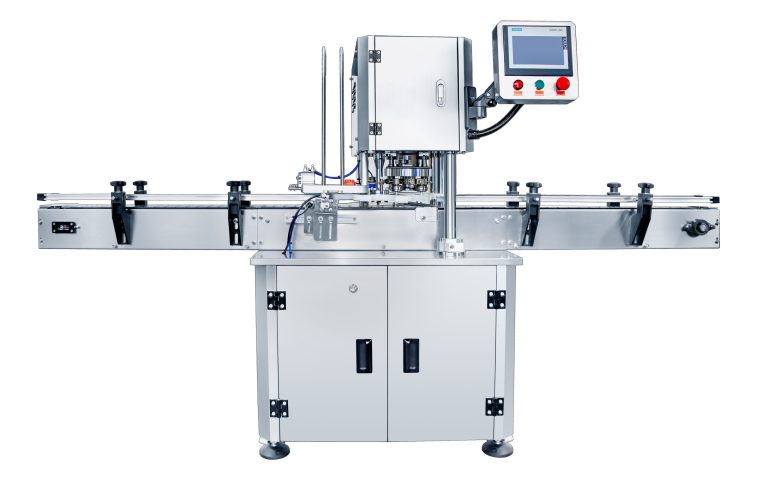

In the highly competitive bottling industry, efficiency, quality, and cost – effectiveness are key factors for success. An automatic double head bottle gripping capping machine offers a range of benefits that make it a worthy investment for bottling companies. Let’s explore the reasons why.

Table of Contents

Enhanced Production Efficiency

Double the Capping Speed

The most obvious advantage of a double – head capping machine is its ability to cap two bottles simultaneously. In a traditional single – head capping setup, each bottle has to go through the capping process one at a time. This can be a time – consuming operation, especially in high – volume production environments. With an automatic double head bottle gripping capping machine, the production speed can be nearly doubled. For example, if a single – head machine can cap 80 bottles per minute, a double – head machine can potentially cap 160 bottles per minute. This significant increase in speed allows bottling companies to meet large orders more quickly and keep up with market demand.

Reduced Downtime

These machines are designed for continuous operation with minimal downtime. They are equipped with advanced sensors and control systems that can detect and correct any issues during the capping process in real – time. For instance, if a cap is misaligned or a bottle is not properly positioned, the machine can automatically stop and make the necessary adjustments. This reduces the chances of product waste and machine breakdowns, ensuring a smooth and uninterrupted production flow. Additionally, the quick – changeover feature of many double – head capping machines allows for easy adjustment between different bottle and cap sizes, further minimizing downtime during product line changes.

Improved Capping Quality

Precise Bottle Gripping

The automatic double head bottle gripping capping machine uses sophisticated gripping technology to hold the bottles firmly in place during the capping process. This is crucial for achieving consistent and accurate capping results. The grippers are adjustable to accommodate different bottle shapes and sizes, ensuring a secure hold without damaging the bottles. By preventing the bottles from moving or wobbling, the machine can apply the correct amount of force to the caps, resulting in a tight and reliable seal.

Consistent Torque Application

One of the challenges in capping is achieving consistent torque across all bottles. Over – tightening or under – tightening caps can lead to product leakage, spoilage, or difficulty for consumers to open the bottles. The double – head capping machine is equipped with torque control systems that can be precisely adjusted. This allows bottling companies to set the optimal torque for each type of cap and bottle combination, ensuring that every bottle is capped with the same level of tightness. This consistency in capping quality helps to maintain product integrity and customer satisfaction.

Cost – Savings in the Long Run

Labor Savings

Investing in an automatic double head bottle gripping capping machine can significantly reduce labor costs. In a manual or semi – automated capping process, multiple workers are required to handle the bottles, place the caps, and operate the capping equipment. With an automatic machine, much of this work is done by the machine itself, reducing the need for a large workforce. This not only saves on direct labor costs but also eliminates the potential for human error and fatigue, which can lead to quality issues and increased production costs.

Reduced Product Waste

As mentioned earlier, the precise capping capabilities of the double – head machine help to minimize product waste. Inaccurate capping can result in bottles being rejected due to leakage or improper sealing. By ensuring consistent and reliable capping, the machine reduces the number of defective products, saving on the cost of raw materials, packaging, and labor associated with re – working or discarding faulty bottles.

Versatility and Adaptability

Compatibility with Different Bottles and Caps

Bottling companies often produce a variety of products in different bottle shapes, sizes, and with various types of caps. The automatic double head bottle gripping capping machine is designed to be highly versatile. It can handle a wide range of bottle materials, such as glass, plastic, and metal, as well as different cap styles, including screw caps, snap – on caps, and corks. This flexibility allows bottling companies to use the same machine for multiple product lines, eliminating the need to invest in separate capping equipment for each type of product.

Easy Integration into Existing Production Lines

These machines are designed to be easily integrated into existing bottling production lines. They can be customized to fit the specific layout and requirements of a company’s production facility. Whether it’s a small – scale operation or a large – scale industrial plant, the double – head capping machine can be seamlessly incorporated into the production process, enhancing overall efficiency without major disruptions.

In conclusion, the automatic double head bottle gripping capping machine offers bottling companies a combination of increased production efficiency, improved capping quality, cost – savings, and versatility. It is a strategic investment that can help companies stay competitive in the dynamic bottling industry.