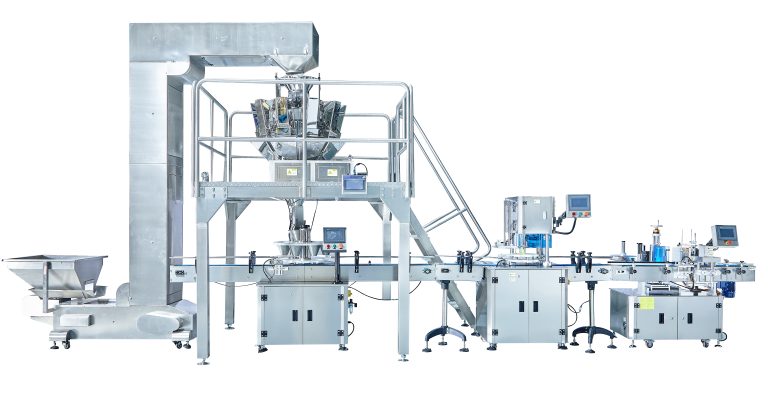

In the world of tin can packaging, the fully auto vacuum nitrogen flushing seaming machine represents a significant advancement.

This sophisticated machine combines several critical functions to ensure the highest quality packaging for various products. The vacuum and nitrogen flushing feature is a game-changer. By removing the air from the tin can and replacing it with nitrogen, it helps to extend the shelf life of the contents. Nitrogen is an inert gas that slows down oxidation and spoilage, preserving the freshness, flavor, and nutritional value of the product inside.

The fully automatic operation of this seaming machine ensures consistent and precise results. It eliminates the potential for human error and greatly increases the speed and efficiency of the packaging process. This is especially important in high-volume production environments where time and accuracy are of the essence.

The seaming function is carried out with utmost precision, creating a tight and secure seal that prevents leaks and protects the contents from external contaminants. The seamless integration of vacuum nitrogen flushing and seaming in one machine simplifies the packaging line and reduces the need for multiple separate operations.

This fully auto vacuum nitrogen flushing seaming machine is highly adaptable and can handle a wide range of tin can sizes and shapes. It can be easily adjusted and programmed to meet the specific requirements of different products and packaging designs.

In terms of maintenance, it is designed for durability and ease of servicing. Regular inspections and proper upkeep can ensure its reliable performance over the long term.

Overall, the fully auto vacuum nitrogen flushing seaming machine for tin can is a cutting-edge solution that enhances product quality, increases production efficiency, and provides a competitive edge in the packaging industry.

Stay tuned to our blogs for more in-depth coverage of the latest innovations in packaging machinery!