It seems we can’t find what you’re looking for. Perhaps searching can help.

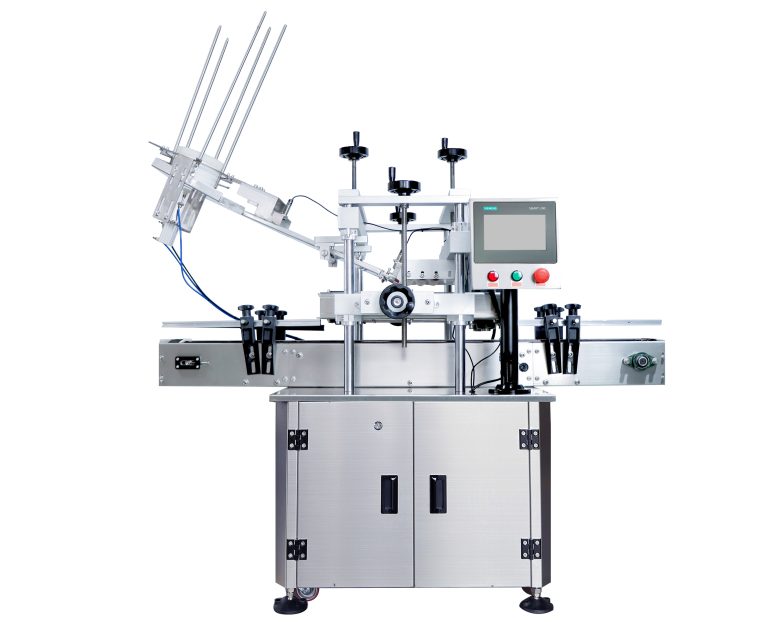

Fully automatic almond powder plastic jar packaging line

Benefits of Using a Fully Automatic Almond Powder Plastic Jar Packaging Line In the world of food packaging, efficiency and precision are key factors in ensuring the quality and safety of products. One of the most popular packaging options for dry food products like almond powder is plastic jars. These…