Table of Contents

Introduction

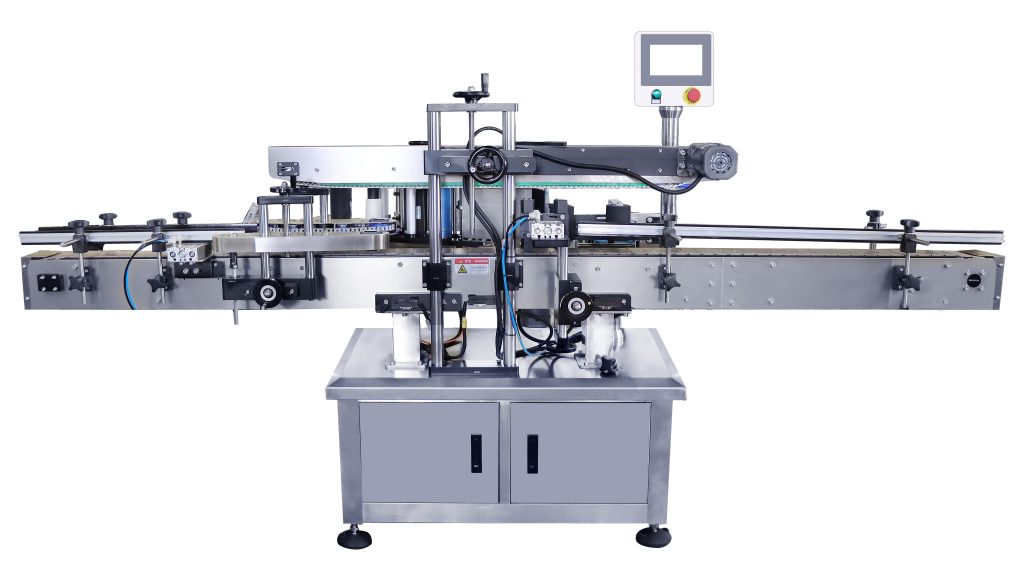

The packaging industry is constantly evolving, driven by the need for greater efficiency, accuracy, and innovation. Among the many technological advancements, the automatic single – side labeling machine has emerged as a revolutionary force, reshaping the way products are labeled and packaged. This article explores how this remarkable machine is bringing about significant changes in the packaging landscape.

Precision and Consistency in Labeling

Eliminating Human Error

Manual labeling is prone to errors such as misaligned labels, smudged prints, or incorrect placement. These mistakes can not only affect the aesthetics of the product but also lead to customer dissatisfaction. The automatic single – side labeling machine, on the other hand, uses advanced sensors and precision mechanisms. For example, it can detect the exact position of a product on the conveyor belt and apply the label with pinpoint accuracy. This ensures that every single product leaving the production line has a perfectly placed label, maintaining a high – quality and professional appearance.

Consistent Label Application

In addition to accuracy, consistency is crucial in the packaging industry. Whether a company is producing a small batch or a large – scale order, the automatic single – side labeling machine delivers uniform results. It can apply labels with the same level of precision, orientation, and tightness across all products. This consistency helps in building brand identity, as consumers come to recognize and trust the standardized look of the labeled products.

Increased Production Speed

High – Volume Labeling

The speed at which an automatic single – side labeling machine operates is one of its most significant advantages. These machines are capable of labeling hundreds or even thousands of products per hour, depending on their configuration. In a busy manufacturing plant, this high – volume labeling capability allows for a continuous and rapid production flow. For instance, in the beverage industry, where large quantities of bottles need to be labeled quickly to meet market demand, the automatic machine can keep up with the pace, ensuring that products are ready for distribution in a timely manner.

Reducing Bottlenecks

Manual labeling can often become a bottleneck in the production process, especially when dealing with large orders. The automatic single – side labeling machine streamlines the labeling process, eliminating the need for multiple workers to apply labels one by one. This not only speeds up the overall production but also allows other parts of the packaging line to operate more efficiently, as there is no longer a delay caused by the labeling step.

Cost – Efficiency

Labor Savings

By automating the labeling process, companies can significantly reduce their labor costs. Instead of hiring a large number of workers for manual labeling, a single operator can oversee the operation of the automatic single – side labeling machine. This not only saves on wages but also reduces the associated costs such as training, benefits, and management. Over time, these savings can add up to a substantial amount, making the investment in the machine a financially viable option for businesses of all sizes.

Reduced Material Waste

The precision of the automatic single – side labeling machine also helps in reducing material waste. Since the labels are applied accurately the first time, there is less need to discard products with misapplied labels. Additionally, the machine can optimize the use of label materials, cutting them to the exact size required and minimizing scrap. This reduction in waste not only saves on material costs but also has a positive environmental impact.

Adaptability and Flexibility

Handling Different Product Types

The automatic single – side labeling machine is designed to be highly adaptable. It can handle a wide variety of product shapes, sizes, and materials. Whether it’s a round bottle, a square box, or a cylindrical container, the machine can be adjusted to apply labels effectively. This versatility makes it suitable for use in multiple industries, from food and beverage to pharmaceuticals and consumer goods.

Accommodating Various Label Designs

In addition to different product types, the machine can also work with a range of label designs. It can handle simple text – only labels as well as complex, multi – colored labels with graphics and barcodes. This flexibility allows companies to change their label designs easily to keep up with marketing trends or regulatory requirements without having to invest in new labeling equipment.

Integration with Other Packaging Systems

Seamless Workflow

The automatic single – side labeling machine can be seamlessly integrated with other packaging systems, such as filling machines, capping machines, and shrink – wrapping machines. This integration creates a smooth and efficient workflow, where products can move through the entire packaging process without interruption. For example, after a product is filled and capped, it can be directly transferred to the labeling machine and then on to the shrink – wrapping station, all in a continuous and automated manner.

Enhanced Data Management

When integrated with other packaging systems, the automatic single – side labeling machine can also contribute to better data management. It can be connected to a central control system that tracks production data, such as the number of labels applied, the type of labels used, and the production speed. This data can be used for quality control, production planning, and inventory management, providing valuable insights for businesses to optimize their operations.

Conclusion

The automatic single – side labeling machine is transforming the packaging industry in numerous ways. Its ability to provide precision and consistency, increase production speed, offer cost – efficiency, adapt to different products and labels, and integrate with other packaging systems makes it an essential tool for modern businesses. As technology continues to advance, we can expect these machines to become even more sophisticated, further revolutionizing the way products are packaged and labeled.