Table of Contents

Benefits of Using a Dry Food Filling Seamer Capping Packaging Line

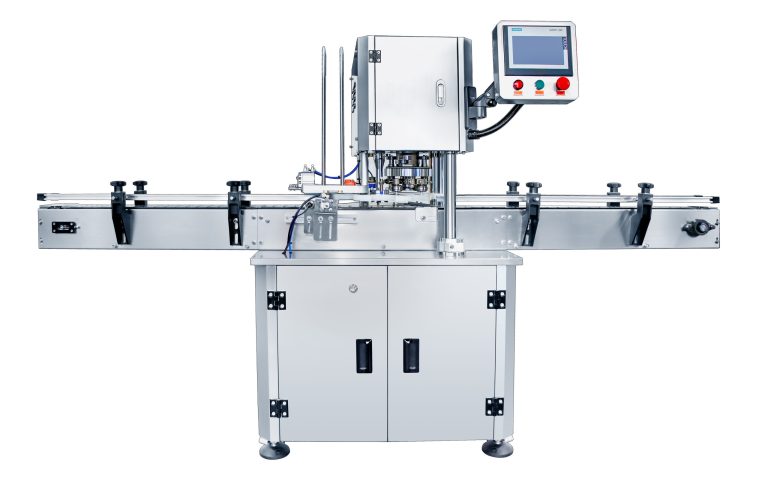

In the food packaging industry, efficiency and precision are key factors in ensuring the quality and safety of products. One essential piece of equipment that plays a crucial role in the packaging process is a dry food filling seamer capping packaging line. This automated system is designed to fill, seal, and cap containers of dry food products, such as grains, nuts, and snacks, with speed and accuracy. There are several benefits to using a dry food filling seamer capping packaging line, which we will explore in this article.

One of the primary advantages of a dry food filling seamer capping packaging line is its ability to increase productivity and reduce labor costs. By automating the filling, sealing, and capping process, this equipment can significantly speed up production and eliminate the need for manual labor. This not only saves time but also reduces the risk of human error, ensuring consistent and precise packaging every time.

Another benefit of using a dry food filling seamer capping packaging line is its versatility and flexibility. These systems are designed to accommodate a wide range of container sizes and shapes, allowing manufacturers to package various types of dry food products with ease. Whether you are packaging small snack bags or large bulk containers, a dry food filling seamer capping packaging line can be customized to meet your specific needs.

In addition to improving efficiency and flexibility, a dry food filling seamer capping packaging line also helps to maintain product quality and freshness. By sealing containers with airtight caps, this equipment helps to preserve the flavor, texture, and shelf life of dry food products. This is especially important for perishable items that are sensitive to moisture and air exposure. With a dry food filling seamer capping packaging line, you can rest assured that your products will remain fresh and intact until they reach the consumer.

Furthermore, using a dry food filling seamer capping packaging line can also enhance the overall appearance of your products. These systems are equipped with advanced technology that ensures a clean and professional finish on each package. From precise filling to secure sealing and capping, a dry food filling seamer capping packaging line can help to elevate the visual appeal of your products, making them more attractive to consumers.

Lastly, investing in a dry food filling seamer capping packaging line can lead to cost savings in the long run. While the initial investment may seem significant, the efficiency and productivity gains that come with this equipment can result in lower operating costs over time. By streamlining the packaging process and reducing waste, a dry food filling seamer capping packaging line can help to improve your bottom line and increase profitability.

In conclusion, the benefits of using a dry food filling seamer capping packaging line are clear. From increased productivity and flexibility to improved product quality and cost savings, this equipment offers a range of advantages for food manufacturers. If you are looking to enhance your packaging process and elevate the quality of your products, consider investing in a dry food filling seamer capping packaging line today.

How to Choose the Right Dry Food Filling Seamer Capping Packaging Line for Your Business

When it comes to packaging dry food products, having the right equipment is essential to ensure efficiency and quality. One key piece of equipment that is crucial for packaging dry food products is a filling seamer capping packaging line. This type of equipment is designed to fill containers with dry food products, seal them with a lid or cap, and then package them for distribution. Choosing the right dry food filling seamer capping packaging line for your business is important to ensure that your products are packaged efficiently and effectively.

There are several factors to consider when choosing a dry food filling seamer capping packaging line for your business. One of the most important factors to consider is the size and capacity of the equipment. You will need to determine how many containers you need to fill and seal per hour in order to meet your production goals. It is important to choose a filling seamer capping packaging line that can handle the volume of products you need to package.

Another important factor to consider when choosing a dry food filling seamer capping packaging line is the type of containers you will be using. Different types of containers require different types of equipment, so it is important to choose a filling seamer capping packaging line that is compatible with the containers you will be using. Whether you are using cans, jars, or pouches, make sure that the equipment you choose is designed to work with the specific type of containers you will be using.

In addition to size and container compatibility, it is also important to consider the speed and efficiency of the filling seamer capping packaging line. Look for equipment that is designed to fill and seal containers quickly and accurately in order to maximize productivity and minimize downtime. A fast and efficient filling seamer capping packaging line can help you meet your production goals and keep up with demand.

Another important factor to consider when choosing a dry food filling seamer capping packaging line is the level of automation and technology that is incorporated into the equipment. Automated equipment can help streamline the packaging process and reduce the risk of human error. Look for filling seamer capping packaging lines that offer features such as automatic lid placement, precise filling controls, and real-time monitoring capabilities to ensure that your products are packaged accurately and efficiently.

When choosing a dry food filling seamer capping packaging line for your business, it is also important to consider the overall cost of the equipment. While it is important to invest in high-quality equipment that will meet your production needs, it is also important to consider your budget and choose equipment that is cost-effective. Look for filling seamer capping packaging lines that offer a good balance of quality and affordability in order to get the best value for your investment.

In conclusion, choosing the right dry food filling seamer capping packaging line for your business is essential to ensure that your products are packaged efficiently and effectively. Consider factors such as size, container compatibility, speed and efficiency, automation and technology, and cost when choosing equipment for your packaging line. By carefully considering these factors, you can choose a filling seamer capping packaging line that meets your production needs and helps your business succeed.