The semi-automatic can closing machine has emerged as a game-changer in the world of packaging, bringing about a revolutionary transformation that is reshaping the industry.

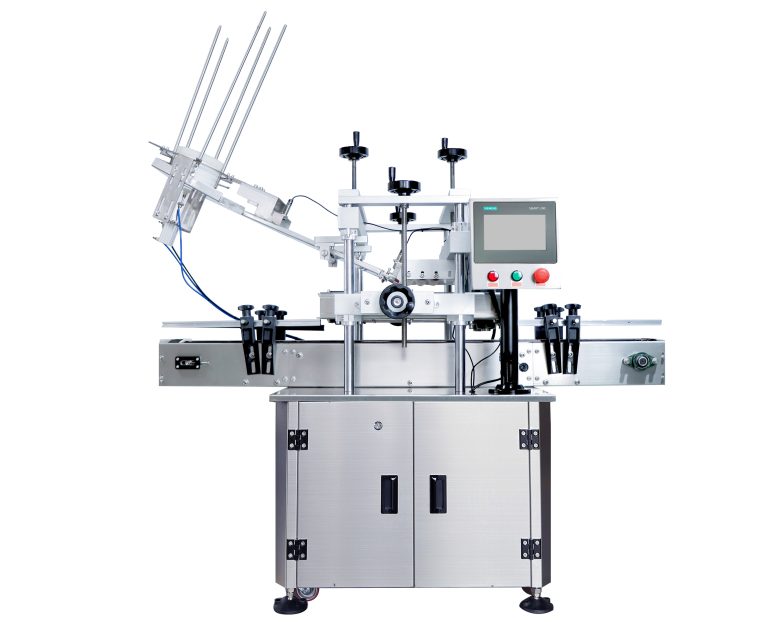

This innovative machine offers a level of efficiency and precision that was previously unachievable. Its semi-automatic operation combines the best of human control and automated processes, allowing for seamless can closing at an accelerated pace.

One of the key ways it revolutionizes packaging is through its enhanced speed. It can close a significant number of cans in a short period, meeting the demands of high-volume production lines without sacrificing quality.

The precision of the semi-automatic can closing machine is another aspect that sets it apart. It ensures a tight and secure seal every time, preventing leaks and maintaining the integrity of the contents inside the cans. This not only prolongs the shelf life of the products but also enhances consumer trust.

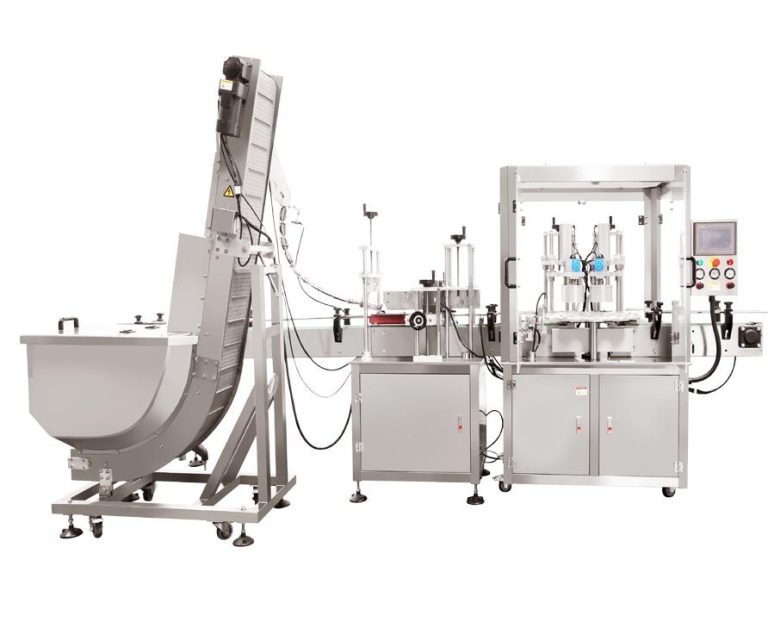

The machine’s flexibility is also a revolutionary feature. It can handle various can sizes and shapes, adapting to the diverse needs of different products and packaging requirements. This adaptability gives manufacturers the freedom to explore new packaging designs and expand their product range.

Furthermore, its user-friendly interface makes it accessible to operators of all skill levels. Minimal training is required to operate the machine effectively, reducing the learning curve and increasing productivity from the get-go.

In conclusion, the semi-automatic can closing machine is truly revolutionizing packaging. It combines speed, precision, flexibility, and ease of use to offer a solution that is driving the industry forward and setting new standards for efficient and reliable can closure.