Table of Contents

Benefits of Using a Plastic Jar Dust Proof Cover Capping Machine

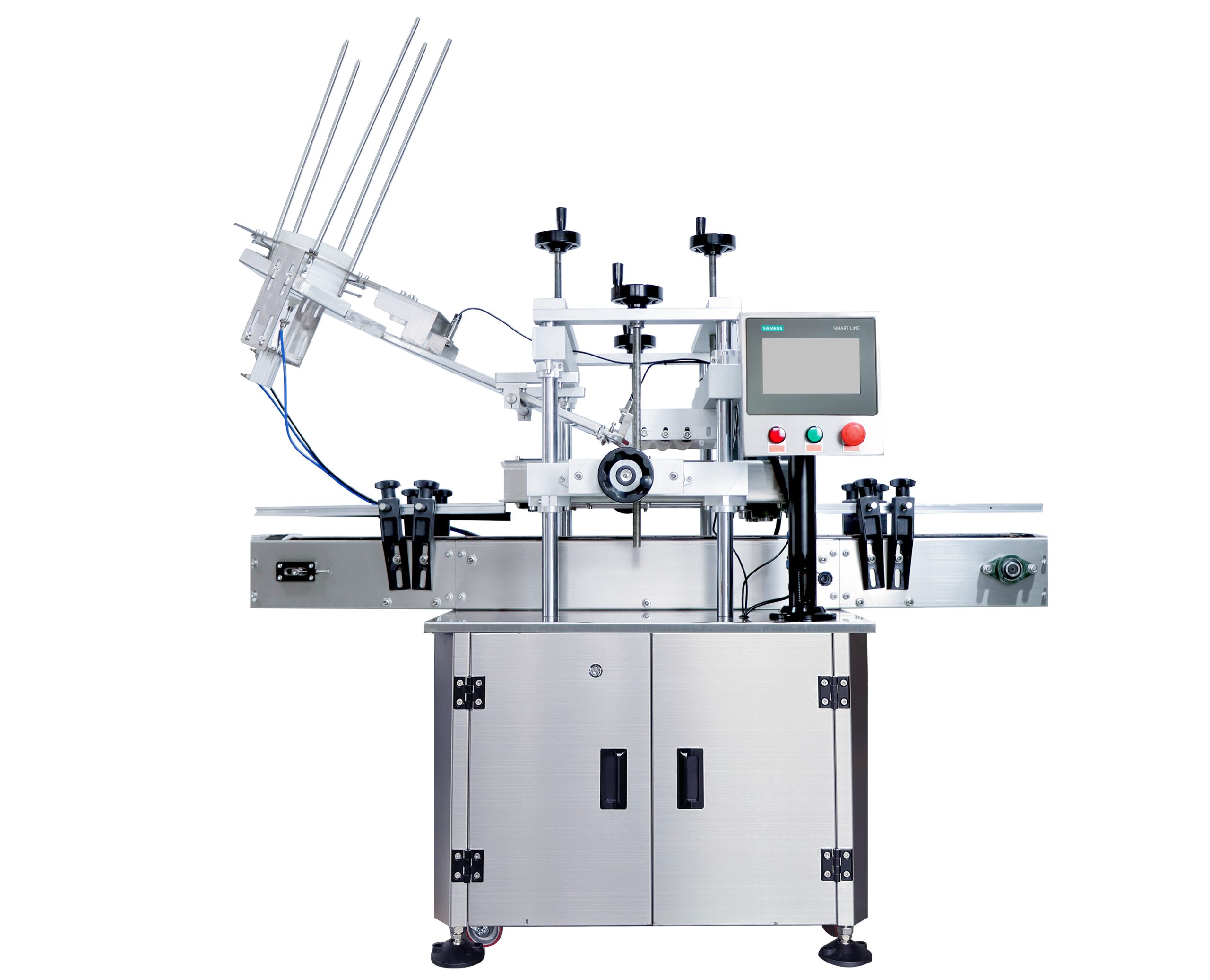

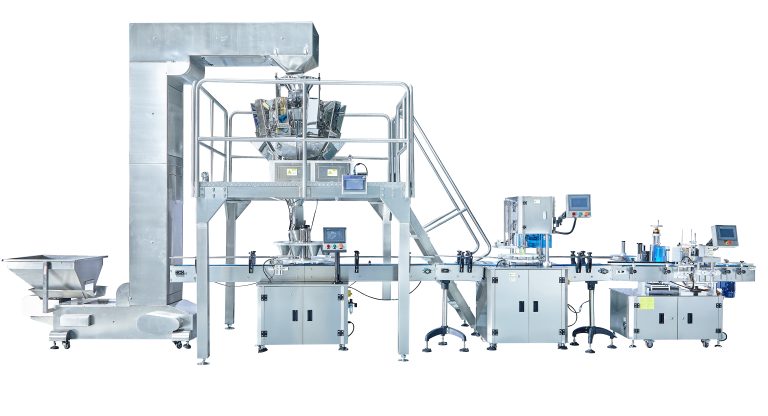

Plastic jar dust proof cover capping machines are essential equipment for businesses in the food, pharmaceutical, and cosmetic industries. These machines offer a wide range of benefits that can help improve efficiency, productivity, and overall product quality.

One of the key benefits of using a plastic jar dust proof cover capping machine is its ability to ensure a tight and secure seal on each jar. This is crucial for maintaining the freshness and quality of the product inside. By using a capping machine, businesses can prevent contamination and spoilage, ultimately reducing waste and saving money in the long run.

Additionally, plastic jar dust proof cover capping machines are designed to handle a variety of jar sizes and shapes, making them versatile and adaptable to different production needs. This flexibility allows businesses to streamline their packaging process and increase output without sacrificing quality.

Another advantage of using a capping machine is the speed and efficiency it offers. These machines are capable of capping hundreds of jars per minute, significantly reducing production time and labor costs. This increased efficiency can help businesses meet tight deadlines and fulfill customer orders in a timely manner.

Furthermore, plastic jar dust proof cover capping machines are easy to operate and require minimal maintenance. This makes them a cost-effective investment for businesses looking to improve their packaging process without incurring additional expenses. With proper training, operators can quickly learn how to use the machine effectively, ensuring smooth and consistent capping results.

In addition to improving efficiency and productivity, capping machines also help enhance the overall appearance of the product. A tight and secure seal on each jar gives consumers confidence in the quality and freshness of the product inside. This can lead to increased customer satisfaction and loyalty, ultimately driving sales and revenue for the business.

Moreover, using a capping machine can also help businesses comply with industry regulations and standards. Properly sealed jars are essential for maintaining product integrity and safety. By investing in a capping machine, businesses can ensure that their products meet all necessary requirements and avoid costly fines or recalls.

Overall, the benefits of using a plastic jar dust proof cover capping machine are clear. From improving efficiency and productivity to enhancing product quality and appearance, these machines offer a wide range of advantages for businesses in various industries. By investing in a capping machine, businesses can streamline their packaging process, reduce waste, and ultimately increase their bottom line.

How to Choose the Right Plastic Jar Dust Proof Cover Capping Machine for Your Business

Plastic jar dust proof cover capping machines are essential equipment for businesses in the food, pharmaceutical, and cosmetic industries. These machines help ensure that products are sealed properly, preventing contamination and extending shelf life. When choosing a plastic jar dust proof cover capping machine for your business, there are several factors to consider to ensure that you select the right machine for your needs.

One of the first things to consider when choosing a plastic jar dust proof cover capping machine is the size and shape of the jars you will be capping. Different machines are designed to handle different sizes and shapes of jars, so it is important to choose a machine that can accommodate the jars you will be using. Additionally, consider the speed at which you will need to cap jars. Some machines are designed for high-speed production, while others are better suited for smaller batches.

Another important factor to consider when choosing a plastic jar dust proof cover capping machine is the type of caps you will be using. Some machines are designed to work with specific types of caps, so it is important to choose a machine that is compatible with the caps you will be using. Additionally, consider whether you will need a machine that can handle different types of caps, such as screw caps, snap-on caps, or flip-top caps.

When choosing a plastic jar dust proof cover capping machine, it is also important to consider the level of automation you require. Some machines are fully automated, while others require manual intervention. Consider the size of your production line and the level of automation that will best suit your needs. Additionally, consider whether you will need a machine that can be easily integrated into your existing production line.

Cost is another important factor to consider when choosing a plastic jar dust proof cover capping machine. Prices can vary widely depending on the size, speed, and level of automation of the machine. Consider your budget and choose a machine that offers the best value for your money. Additionally, consider the long-term costs of maintenance and repairs when choosing a machine.

When choosing a plastic jar dust proof cover capping machine, it is important to consider the reputation of the manufacturer. Look for a manufacturer with a proven track record of producing high-quality machines that are reliable and durable. Additionally, consider the level of customer support and service offered by the manufacturer, as this can be crucial in ensuring that your machine operates smoothly and efficiently.

In conclusion, choosing the right plastic jar dust proof cover capping machine for your business is essential to ensuring the quality and safety of your products. Consider factors such as the size and shape of your jars, the type of caps you will be using, the level of automation you require, and the cost of the machine. Additionally, consider the reputation of the manufacturer and the level of customer support offered. By carefully considering these factors, you can choose a machine that meets your needs and helps your business succeed.

Maintenance Tips for Ensuring Optimal Performance of Your Plastic Jar Dust Proof Cover Capping Machine

Plastic jar dust proof cover capping machines are essential equipment in many industries, as they help ensure that products are securely sealed and protected from contaminants. To ensure that your capping machine operates at its best and delivers consistent results, regular maintenance is key. In this article, we will discuss some maintenance tips to help you keep your plastic jar dust proof cover capping machine in optimal condition.

First and foremost, it is important to regularly clean your capping machine to prevent dust and debris from accumulating and affecting its performance. Use a soft cloth or brush to remove any dirt or residue from the machine’s components, paying special attention to the capping head and conveyor belts. Additionally, make sure to lubricate moving parts as needed to prevent friction and wear.

Another important maintenance tip is to regularly inspect the machine for any signs of wear or damage. Check for loose or worn out parts, such as belts, gears, or seals, and replace them as needed. It is also important to check the alignment of the capping head to ensure that it is properly centered and functioning correctly.

In addition to regular cleaning and inspection, it is important to calibrate your capping machine periodically to ensure accurate and consistent capping results. Follow the manufacturer’s guidelines for calibration and make any necessary adjustments to the machine’s settings to achieve optimal performance.

Furthermore, it is important to train your staff on proper machine operation and maintenance procedures to prevent any mishaps or damage to the equipment. Make sure that all operators are familiar with the machine’s controls and safety features, and provide them with the necessary tools and resources to perform routine maintenance tasks.

Lastly, it is important to keep a record of all maintenance activities performed on the capping machine, including cleaning, inspection, calibration, and repairs. This will help you track the machine’s performance over time and identify any recurring issues that may require further attention.

In conclusion, regular maintenance is essential for ensuring optimal performance of your plastic jar dust proof cover capping machine. By following these maintenance tips and staying proactive in caring for your equipment, you can extend its lifespan, prevent costly repairs, and ensure that your products are consistently sealed and protected. Remember, a well-maintained capping machine is a reliable and efficient asset to your business.

-768x622.jpg)