Table of Contents

Benefits of Using Hot Paste Viscous Liquid Filling Machine

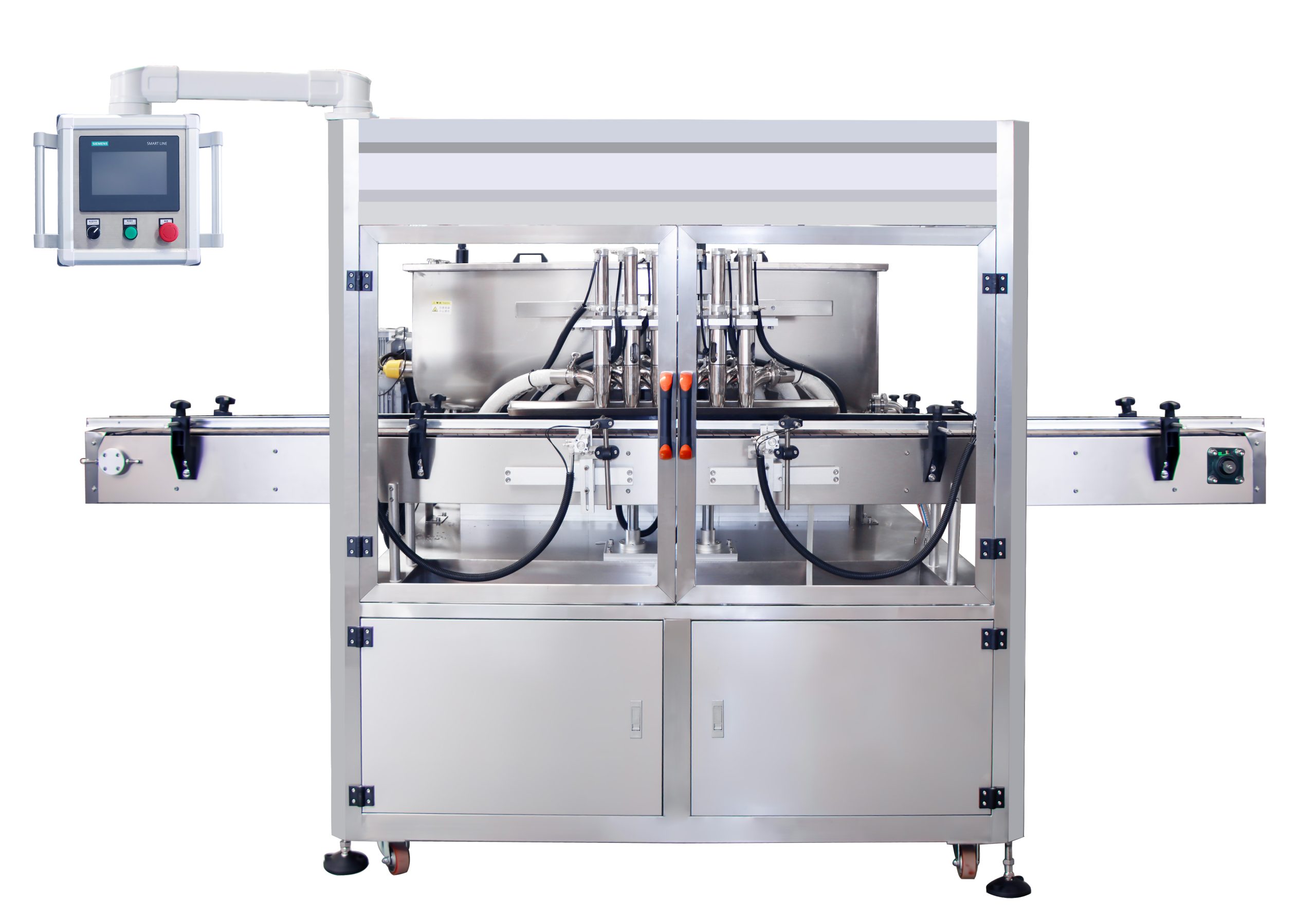

Hot paste viscous liquid filling machines are essential equipment for industries that deal with products such as sauces, creams, gels, and other viscous liquids. These machines offer a wide range of benefits that can significantly improve the efficiency and productivity of a production line.

One of the key benefits of using a hot paste viscous liquid filling machine is its ability to accurately fill containers with a consistent amount of product. This is crucial for maintaining product quality and ensuring that customers receive the correct amount of product in each container. The machine’s precision filling capabilities help reduce product waste and minimize the risk of underfilling or overfilling containers.

In addition to accuracy, hot paste viscous liquid filling machines are also designed to handle a wide range of container sizes and shapes. This versatility allows manufacturers to fill various types of containers without the need for multiple machines or manual adjustments. This not only saves time but also increases production flexibility, allowing manufacturers to quickly adapt to changing market demands.

Furthermore, hot paste viscous liquid filling machines are equipped with advanced technology that ensures the efficient and reliable operation of the equipment. These machines are designed to handle high-viscosity liquids with ease, preventing clogs and ensuring a smooth filling process. The machines are also equipped with features such as automatic cleaning systems and self-diagnostic capabilities, reducing downtime and maintenance costs.

Another significant benefit of using a hot paste viscous liquid filling machine is its ability to improve overall production efficiency. These machines are capable of filling a large number of containers in a short amount of time, increasing production output and reducing labor costs. The automated filling process also minimizes the risk of human error, resulting in higher product quality and consistency.

Additionally, hot paste viscous liquid filling machines are designed to meet strict industry standards and regulations, ensuring that products are filled and sealed in a safe and hygienic manner. This is particularly important for industries such as food and pharmaceuticals, where product safety and quality are of utmost importance. By using a hot paste viscous liquid filling machine, manufacturers can ensure that their products meet the highest standards of quality and safety.

Overall, hot paste viscous liquid filling machines offer a wide range of benefits that can significantly improve the efficiency and productivity of a production line. From accurate filling and versatile container handling to advanced technology and improved production efficiency, these machines are essential equipment for industries that deal with viscous liquids. By investing in a hot paste viscous liquid filling machine, manufacturers can streamline their production process, reduce costs, and ensure the highest quality and safety standards for their products.

How to Choose the Right Hot Paste Viscous Liquid Filling Machine for Your Business

When it comes to filling machines for hot paste viscous liquids, there are several factors to consider in order to choose the right one for your business. These machines are essential for efficiently filling containers with products such as sauces, creams, and gels. In this article, we will discuss the key considerations to keep in mind when selecting a hot paste viscous liquid filling machine.

One of the first things to consider is the type of hot paste viscous liquid you will be filling. Different types of liquids have different viscosities, which can affect the type of filling machine that is best suited for the job. For example, a thick sauce may require a piston filling machine, while a thinner gel may be better suited for a gravity filling machine. It is important to choose a machine that is designed to handle the specific viscosity of the liquid you will be filling.

Another important consideration is the speed at which you need to fill containers. Some hot paste viscous liquid filling machines are designed for high-speed production, while others are better suited for slower, more precise filling. If you have a high-volume production line, you will want to choose a machine that can keep up with the demand. On the other hand, if you have a smaller operation, a slower machine may be more cost-effective.

In addition to viscosity and speed, it is also important to consider the size and shape of the containers you will be filling. Some hot paste viscous liquid filling machines are designed for filling bottles, while others are better suited for filling jars or tubes. It is important to choose a machine that is compatible with the containers you will be using in order to ensure a smooth and efficient filling process.

Another important factor to consider is the level of automation you require. Some hot paste viscous liquid filling machines are fully automated, while others require more manual intervention. If you have a high-volume production line, you may want to invest in a fully automated machine to increase efficiency and reduce labor costs. However, if you have a smaller operation, a semi-automated machine may be more suitable.

When choosing a hot paste viscous liquid filling machine, it is also important to consider the overall quality and reliability of the machine. Look for a machine that is made from high-quality materials and is built to last. It is also a good idea to choose a machine from a reputable manufacturer with a track record of producing reliable equipment.

In conclusion, choosing the right hot paste viscous liquid filling machine for your business is a crucial decision that can have a significant impact on your production process. By considering factors such as viscosity, speed, container size, automation level, and overall quality, you can select a machine that meets your specific needs and helps you achieve your production goals. Take the time to research and compare different machines to find the best fit for your business.

Maintenance Tips for Hot Paste Viscous Liquid Filling Machine

Hot paste viscous liquid filling machines are essential equipment in various industries, including food, pharmaceutical, and cosmetic industries. These machines are designed to accurately fill containers with hot paste or viscous liquids, ensuring efficiency and precision in the production process. To maintain the optimal performance of a hot paste viscous liquid filling machine, it is crucial to follow proper maintenance practices. In this article, we will discuss some maintenance tips to help you keep your filling machine in top condition.

Regular cleaning is essential for the proper functioning of a hot paste viscous liquid filling machine. Residue from hot paste or viscous liquids can build up over time and clog the machine, leading to inefficiency and potential breakdowns. To prevent this, it is recommended to clean the machine thoroughly after each use. Use a mild detergent and warm water to clean the machine, paying special attention to areas where residue tends to accumulate. Regular cleaning will not only prolong the life of the machine but also ensure the quality of the filled products.

In addition to regular cleaning, it is important to inspect the machine for any signs of wear and tear. Check for loose or damaged parts, such as seals, gaskets, and hoses, and replace them as needed. Regular inspection will help you identify potential issues before they escalate into major problems, saving you time and money on repairs. It is also advisable to lubricate moving parts regularly to prevent friction and ensure smooth operation of the machine.

Calibrating a hot paste viscous liquid filling machine is another important maintenance task that should not be overlooked. Proper calibration ensures accurate filling volumes and prevents overfilling or underfilling of containers. Follow the manufacturer’s guidelines for calibration and make adjustments as needed to maintain the accuracy of the machine. Regular calibration will help you achieve consistent results and meet quality standards in your production process.

Maintaining a clean and organized work environment is also crucial for the proper functioning of a hot paste viscous liquid filling machine. Keep the area around the machine free of clutter and debris to prevent accidents and ensure easy access for maintenance tasks. Store spare parts and cleaning supplies in a designated area to keep them organized and readily available when needed. A well-maintained work environment will not only improve the efficiency of the machine but also create a safe and productive workspace for your employees.

Lastly, it is important to train your staff on proper maintenance procedures for the hot paste viscous liquid filling machine. Provide training on cleaning techniques, inspection procedures, and calibration methods to ensure that your employees are equipped to handle maintenance tasks effectively. Encourage open communication between staff members and management to address any maintenance issues promptly and prevent them from escalating into major problems.

In conclusion, proper maintenance is essential for the optimal performance of a hot paste viscous liquid filling machine. By following the maintenance tips outlined in this article, you can ensure that your machine operates efficiently, produces high-quality filled products, and has a longer lifespan. Regular cleaning, inspection, calibration, and training are key components of a successful maintenance program for your filling machine. By investing time and effort in maintenance, you can maximize the productivity and profitability of your production process.