Table of Contents

Benefits of Using Small Granules Filling Seaming Labeling Machine Line for Chia Seeds

Chia seeds have gained popularity in recent years due to their numerous health benefits. They are packed with nutrients such as omega-3 fatty acids, fiber, protein, and antioxidants. As a result, many people are incorporating chia seeds into their diets to improve their overall health and well-being. However, packaging chia seeds can be a tedious and time-consuming process, especially for businesses looking to mass-produce and distribute them.

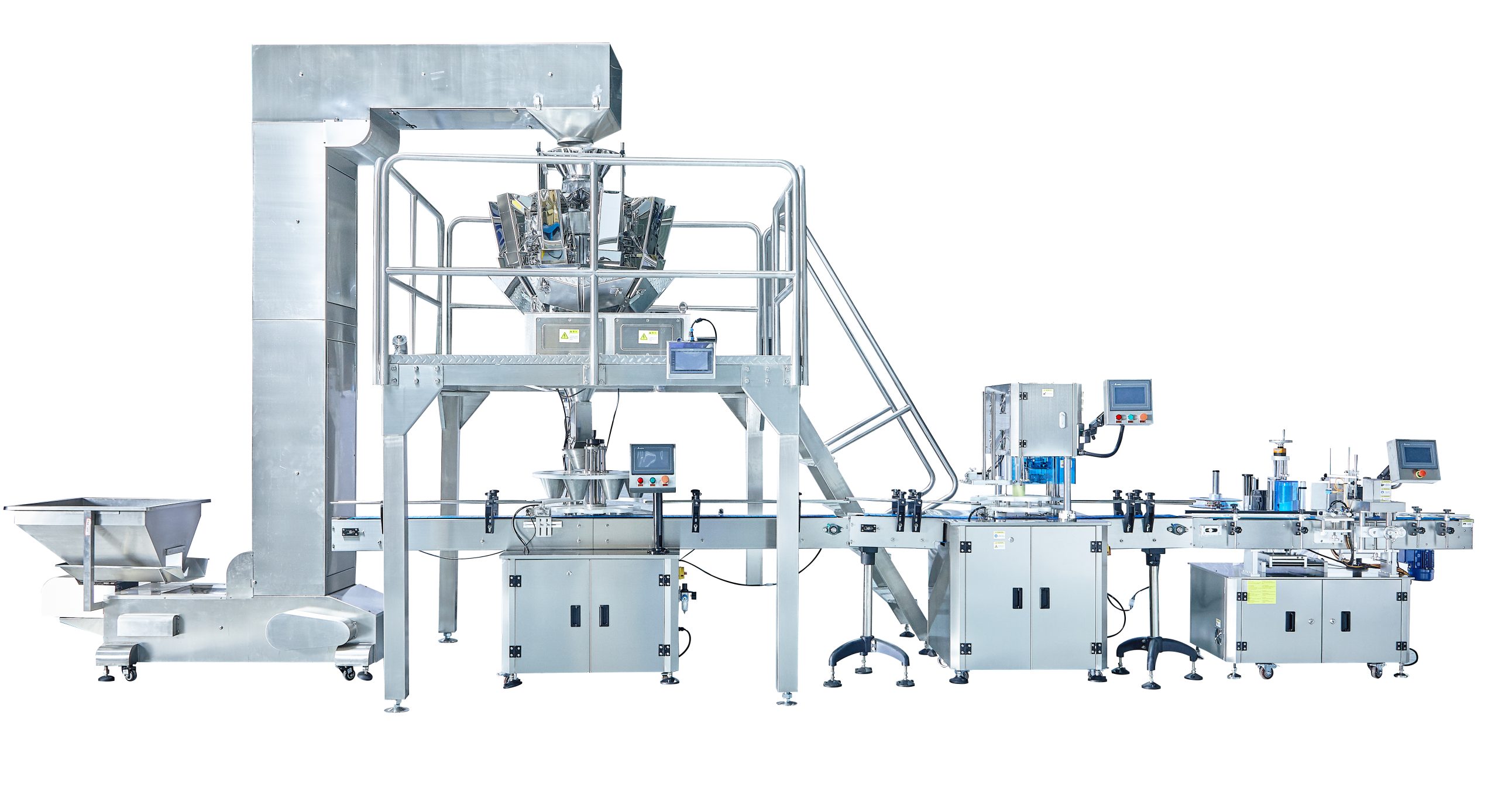

This is where small granules filling seaming labeling machine lines come into play. These machines are specifically designed to efficiently fill, seal, and label small granules such as chia seeds. By using a small granules filling seaming labeling machine line, businesses can streamline their production process and increase their output significantly.

One of the main benefits of using a small granules filling seaming labeling machine line for chia seeds is the speed and efficiency it offers. These machines are capable of filling and sealing hundreds of packets per minute, which is much faster than manual packaging methods. This allows businesses to meet the high demand for chia seeds in a timely manner and keep up with market trends.

In addition to speed, small granules filling seaming labeling machine lines also ensure accuracy and consistency in packaging. These machines are equipped with advanced technology that accurately measures and dispenses the right amount of chia seeds into each packet. This helps businesses maintain quality control and ensure that every packet contains the correct amount of product, which is crucial for customer satisfaction and brand reputation.

Furthermore, small granules filling seaming labeling machine lines are versatile and can be customized to meet the specific needs of businesses. Whether it’s adjusting the fill weight, changing the packet size, or adding custom labels, these machines can be tailored to suit different packaging requirements. This flexibility allows businesses to adapt to changing market demands and stay ahead of the competition.

Another key benefit of using a small granules filling seaming labeling machine line for chia seeds is the reduction in labor costs. By automating the packaging process, businesses can significantly reduce the need for manual labor and free up employees to focus on other tasks. This not only saves time and money but also improves overall efficiency and productivity in the long run.

Moreover, small granules filling seaming labeling machine lines are designed to be user-friendly and easy to operate. Businesses can train their employees to use these machines quickly and efficiently, reducing the learning curve and minimizing downtime. This ensures a smooth transition to automated packaging and allows businesses to start reaping the benefits of increased production and profitability sooner.

In conclusion, small granules filling seaming labeling machine lines offer numerous benefits for businesses looking to package chia seeds efficiently and effectively. From speed and accuracy to versatility and cost savings, these machines are a valuable investment for businesses in the food industry. By incorporating a small granules filling seaming labeling machine line into their production process, businesses can streamline their operations, increase their output, and stay competitive in the market.

How to Choose the Right Small Granules Filling Seaming Labeling Machine Line for Chia Seeds

Chia seeds have gained popularity in recent years due to their numerous health benefits and versatility in cooking. As a result, many businesses are looking to capitalize on this trend by offering chia seeds in various packaging options. One popular choice for packaging chia seeds is in small granules, which can be easily dispensed and used in recipes.

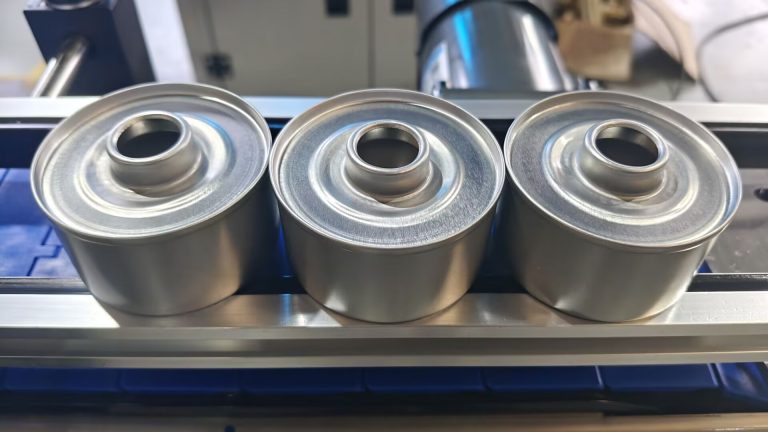

When it comes to packaging small granules like chia seeds, a filling seaming labeling machine line is essential for ensuring efficiency and accuracy in the packaging process. These machines are designed to fill containers with granules, seal them, and apply labels, all in one seamless process. However, with so many options available on the market, it can be overwhelming to choose the right machine for your business.

One important factor to consider when choosing a small granules filling seaming labeling machine line for chia seeds is the capacity of the machine. You will need to determine how many containers you plan to fill and label per hour to ensure that the machine can keep up with your production needs. Additionally, consider the size and shape of the containers you will be using, as this will impact the type of machine that is best suited for your needs.

Another important consideration is the level of automation you require in a filling seaming labeling machine line. Some machines are fully automated, requiring minimal human intervention, while others may require more manual labor. Depending on your budget and production volume, you will need to decide which level of automation is right for your business.

In addition to capacity and automation, it is important to consider the accuracy and precision of the machine. Chia seeds are small and delicate, so it is crucial that the machine can accurately fill containers with the correct amount of seeds without damaging them. Look for machines that offer precise filling and sealing capabilities to ensure that your product meets quality standards.

Furthermore, consider the versatility of the machine in terms of packaging options. Some machines are designed to fill and seal only one type of container, while others offer more flexibility in terms of container size and shape. If you plan to offer chia seeds in a variety of packaging options, look for a machine that can accommodate your needs.

When choosing a small granules filling seaming labeling machine line for chia seeds, it is also important to consider the overall cost of the machine. While it may be tempting to opt for the cheapest option available, it is important to weigh the upfront cost against the long-term benefits of investing in a high-quality machine. Look for machines that offer a good balance of affordability and quality to ensure that you get the best value for your money.

In conclusion, choosing the right small granules filling seaming labeling machine line for chia seeds is essential for ensuring efficiency and accuracy in the packaging process. Consider factors such as capacity, automation, accuracy, versatility, and cost when making your decision. By taking the time to research and evaluate your options, you can find a machine that meets your production needs and helps your business succeed in the competitive chia seed market.

Maintenance Tips for Small Granules Filling Seaming Labeling Machine Line for Chia Seeds

Maintaining a small granules filling seaming labeling machine line for chia seeds is essential to ensure smooth operations and high-quality output. Regular maintenance not only prolongs the lifespan of the equipment but also helps prevent breakdowns and costly repairs. In this article, we will discuss some key maintenance tips for keeping your small granules filling seaming labeling machine line in top condition.

One of the most important maintenance tasks for a small granules filling seaming labeling machine line is regular cleaning. Chia seeds can be sticky and prone to clumping, which can lead to blockages in the machine. It is important to clean the machine thoroughly after each use to remove any residue and prevent buildup. Use a soft brush or cloth to clean the filling nozzles, hoppers, and conveyor belts. Pay special attention to areas where chia seeds tend to accumulate, such as corners and crevices.

In addition to regular cleaning, it is important to inspect the machine for any signs of wear and tear. Check for loose or damaged parts, such as belts, seals, and bearings. Replace any worn or damaged parts immediately to prevent further damage to the machine. It is also a good idea to lubricate moving parts regularly to ensure smooth operation. Use a high-quality lubricant recommended by the manufacturer to prevent friction and reduce wear on the machine.

Another important maintenance task for a small granules filling seaming labeling machine line is calibrating the equipment. Over time, the machine may become misaligned, leading to inaccurate filling and labeling. It is important to calibrate the machine regularly to ensure precise measurements and consistent output. Follow the manufacturer’s instructions for calibrating the machine and make any necessary adjustments to ensure accurate filling and labeling.

In addition to regular cleaning, inspection, and calibration, it is important to train your staff on proper machine operation and maintenance. Make sure that all operators are familiar with the machine’s functions and know how to troubleshoot common issues. Provide training on proper cleaning procedures, maintenance tasks, and safety precautions to prevent accidents and ensure the longevity of the equipment. Encourage your staff to report any issues or concerns with the machine promptly to prevent further damage.

Finally, it is important to keep detailed records of maintenance tasks and repairs performed on the machine. This will help you track the machine’s performance over time and identify any recurring issues. Keep a log of cleaning schedules, calibration dates, and parts replacements to ensure that the machine is well-maintained and operating at peak efficiency. Regular maintenance and record-keeping will help you identify potential problems early and prevent costly repairs down the line.

In conclusion, maintaining a small granules filling seaming labeling machine line for chia seeds is essential to ensure smooth operations and high-quality output. Regular cleaning, inspection, calibration, staff training, and record-keeping are key maintenance tasks that will help prolong the lifespan of the equipment and prevent breakdowns. By following these maintenance tips, you can keep your small granules filling seaming labeling machine line in top condition and ensure consistent and accurate filling and labeling of chia seeds.