In the dynamic world of packaging, staying ahead of the curve is essential for businesses to thrive. The automatic paging labeling machine has emerged as a revolutionary force, transforming the way products are labeled and packaged. This remarkable piece of equipment is not just an upgrade; it’s a game – changer that brings a multitude of benefits to the packaging industry.

Table of Contents

The Packaging Landscape Before the Automatic Paging Labeling Machine

Before the advent of the automatic paging labeling machine, the packaging process was fraught with challenges. Manual labeling was the norm in many small and medium – sized enterprises. Workers would spend hours carefully applying labels to products, which was not only time – consuming but also prone to errors. Misaligned labels, smudged printing, and inconsistent application were common issues that affected the overall quality of the packaged products.

Even semi – automated labeling systems had their limitations. They often required significant operator intervention, were slow in adapting to different product sizes and label types, and lacked the precision needed for high – end packaging. These inefficiencies led to increased production costs, lower productivity, and a negative impact on brand image.

How the Automatic Paging Labeling Machine Transforms Packaging

Precision and Consistency

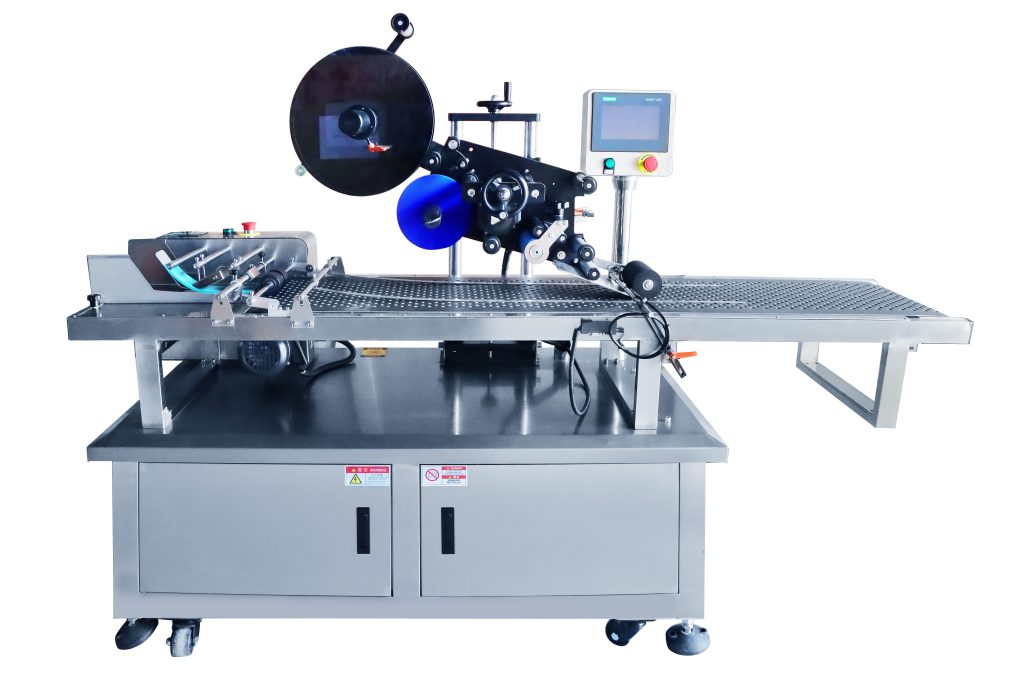

One of the most significant advantages of the automatic paging labeling machine is its ability to deliver unparalleled precision and consistency. Using advanced sensors and servo – motor technology, the machine can accurately position labels on products with a high degree of repeatability. Whether it’s a small vial or a large box, the labels are applied exactly where they should be, every single time.

This precision is crucial for maintaining brand integrity. A perfectly aligned label enhances the visual appeal of the product, making it more attractive to consumers on the shelves. In industries where regulatory requirements demand accurate label placement, such as the pharmaceutical and food industries, the automatic paging labeling machine ensures compliance with ease.

High – Speed Labeling

In today’s fast – paced market, speed is of the essence. The automatic paging labeling machine is designed to operate at high speeds, significantly increasing the throughput of the packaging line. It can label hundreds or even thousands of products per hour, depending on the model and the complexity of the labeling task.

This high – speed operation allows businesses to meet large – scale production demands efficiently. For example, in a beverage manufacturing plant, the machine can quickly label bottles as they move along the conveyor belt, keeping up with the rapid pace of the filling and packaging process. As a result, companies can reduce production bottlenecks, increase output, and ultimately improve their bottom line.

Versatility

The automatic paging labeling machine is incredibly versatile, capable of handling a wide variety of products and label types. It can be easily configured to accommodate different shapes, sizes, and materials of products, including round, square, rectangular, and irregularly shaped items.

Moreover, it can apply various types of labels, such as self – adhesive labels, pressure – sensitive labels, and shrink sleeves. This versatility makes it suitable for a diverse range of industries, from cosmetics and personal care to electronics and automotive parts. Businesses can use the same machine for multiple product lines, eliminating the need for separate labeling equipment and reducing capital expenditure.

Integration with Packaging Lines

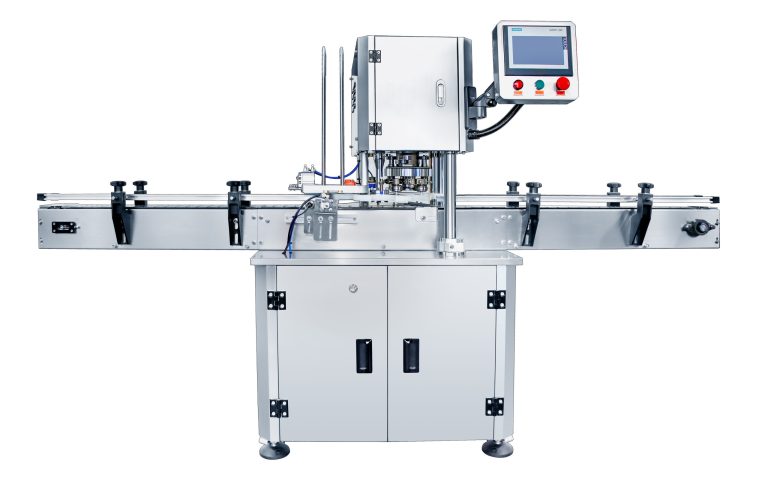

The automatic paging labeling machine is designed to seamlessly integrate with existing packaging lines. It can be connected to other equipment, such as filling machines, capping machines, and inspection systems, creating a fully automated and efficient packaging process.

This integration allows for real – time data exchange between different machines, enabling better control and monitoring of the entire packaging line. For example, if a product fails an inspection, the labeling machine can be programmed to skip labeling that particular item, preventing defective products from reaching the market.

The Business Impact of the Automatic Paging Labeling Machine

Cost Savings

By automating the labeling process, businesses can achieve significant cost savings. The reduction in labor costs is immediate, as fewer workers are required to perform the labeling task. Additionally, the high – speed operation and precision of the machine reduce the number of rejected products due to poor labeling, which saves on material costs and waste disposal.

Competitive Advantage

In a crowded marketplace, having a competitive edge is crucial. The automatic paging labeling machine enables businesses to produce high – quality, professionally labeled products at a faster rate than their competitors. This not only improves customer satisfaction but also helps to build a strong brand reputation.

Scalability

As businesses grow and their production demands increase, the automatic paging labeling machine can easily scale to meet these needs. It can be upgraded with additional features or capacity, allowing companies to expand their operations without having to invest in entirely new equipment.

In conclusion, the automatic paging labeling machine is a true game – changer in the packaging industry. Its precision, speed, versatility, and integration capabilities offer businesses a way to overcome the challenges of traditional labeling methods and achieve greater efficiency, cost savings, and competitiveness. By unleashing the power of this remarkable machine, companies can take their packaging operations to new heights.