Table of Contents

Benefits of Using Puffed Food Filling Packaging Production Line

Puffed food products have become increasingly popular in recent years due to their light and crispy texture, as well as their delicious flavors. To meet the growing demand for these products, many food manufacturers are turning to puffed food filling packaging production lines to streamline their production process and improve efficiency.

One of the key benefits of using a puffed food filling packaging production line is the ability to automate the entire production process. This not only saves time and labor costs but also ensures consistency in the quality of the final product. By using automated equipment, manufacturers can produce large quantities of puffed food products quickly and efficiently, allowing them to meet the demands of their customers in a timely manner.

In addition to improving efficiency, puffed food filling packaging production lines also help to reduce waste. By using precise measurements and cutting techniques, manufacturers can minimize the amount of raw materials that are wasted during the production process. This not only helps to reduce costs but also has a positive impact on the environment by reducing the amount of food waste that ends up in landfills.

Another benefit of using a puffed food filling packaging production line is the ability to customize the packaging of the final product. With automated equipment, manufacturers can easily adjust the size, shape, and design of the packaging to meet the specific needs of their customers. This level of customization not only helps to attract consumers but also allows manufacturers to differentiate their products from competitors in the market.

Furthermore, puffed food filling packaging production lines are designed to meet strict food safety standards. By using equipment that is made from high-quality materials and meets industry regulations, manufacturers can ensure that their products are safe for consumption. This not only helps to protect the health of consumers but also helps to build trust and loyalty among customers.

Additionally, puffed food filling packaging production lines are designed to be easy to clean and maintain. This helps to reduce the risk of contamination and ensures that the final product meets the highest standards of quality. By investing in a puffed food filling packaging production line, manufacturers can rest assured that their products are being produced in a clean and sanitary environment.

Overall, the benefits of using a puffed food filling packaging production line are clear. From improving efficiency and reducing waste to customizing packaging and ensuring food safety, these production lines offer a wide range of advantages for food manufacturers. By investing in this technology, manufacturers can stay ahead of the competition and meet the growing demand for puffed food products in the market.

How to Optimize Efficiency in Puffed Food Filling Packaging Production Line

Puffed food products have become increasingly popular in recent years, with consumers seeking out convenient and tasty snacks that can be enjoyed on the go. As a result, manufacturers of puffed food items are constantly looking for ways to optimize their production processes to meet the growing demand for these products. One key area where efficiency can be improved is in the filling and packaging of puffed food items.

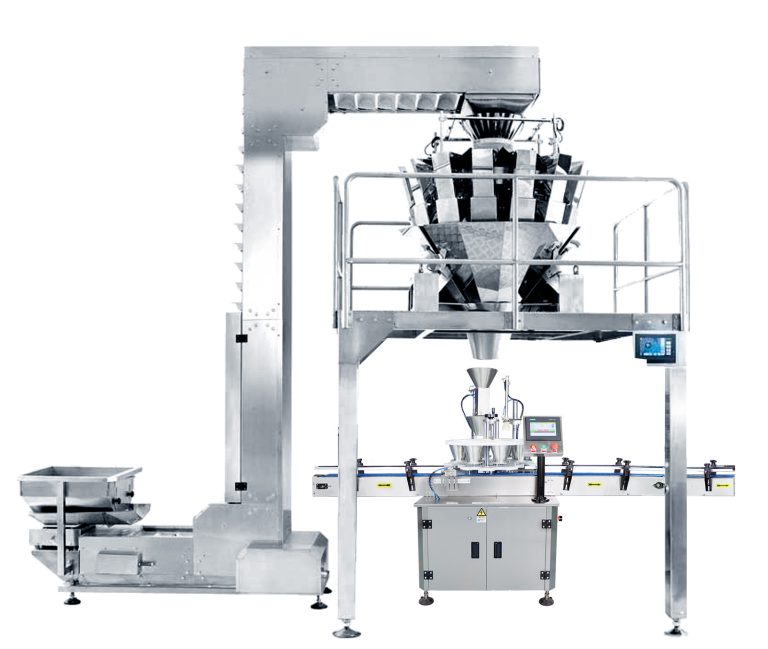

To optimize efficiency in a puffed food filling packaging production line, it is important to first understand the various components of the production process. This typically involves several stages, including filling the puffed food product into the packaging, sealing the packaging, and labeling the finished product. Each of these stages plays a crucial role in ensuring that the final product meets quality standards and is ready for distribution to consumers.

One way to improve efficiency in the filling and packaging process is to invest in automated equipment that can streamline the production line. Automated filling machines can accurately measure and dispense the correct amount of puffed food product into each package, reducing the risk of human error and ensuring consistency in the final product. Similarly, automated sealing and labeling machines can help to speed up the packaging process and ensure that each package is properly sealed and labeled before being sent out for distribution.

In addition to investing in automated equipment, it is also important to regularly maintain and calibrate the machinery used in the production line. This can help to prevent breakdowns and ensure that the equipment is operating at peak efficiency. Regular maintenance can also help to identify any potential issues before they become major problems, allowing for quick and efficient repairs to be made.

Another key factor in optimizing efficiency in a puffed food filling packaging production line is to carefully monitor and analyze production data. By tracking key performance indicators such as production output, downtime, and waste levels, manufacturers can identify areas where improvements can be made and implement strategies to increase efficiency. For example, if a particular machine is consistently causing downtime, it may be worth investing in a replacement or upgrading the equipment to prevent future disruptions.

Furthermore, implementing lean manufacturing principles can help to streamline the production process and eliminate waste. By identifying and eliminating non-value-added activities, manufacturers can reduce production costs and improve overall efficiency. This may involve reorganizing workstations, optimizing production flow, or implementing just-in-time inventory management practices to minimize waste and improve productivity.

Overall, optimizing efficiency in a puffed food filling packaging production line requires a combination of investment in automated equipment, regular maintenance and calibration of machinery, monitoring and analyzing production data, and implementing lean manufacturing principles. By taking a holistic approach to improving efficiency, manufacturers can increase production output, reduce costs, and meet the growing demand for puffed food products in the market.

Latest Innovations in Puffed Food Filling Packaging Production Line Technology

In recent years, the demand for puffed food products has been on the rise, leading to a need for more efficient and advanced packaging solutions. One of the latest innovations in this field is the puffed food filling packaging production line, which offers a streamlined and automated process for packaging these popular snacks.

The puffed food filling packaging production line is designed to handle the entire packaging process, from filling the bags with the puffed food product to sealing them for freshness. This automated system helps to increase efficiency and reduce the risk of human error, ensuring that each bag is filled and sealed correctly every time.

One of the key features of the puffed food filling packaging production line is its ability to handle a wide range of bag sizes and styles. This flexibility allows manufacturers to package their products in various formats, catering to different customer preferences and market demands. Whether it’s small snack-sized bags or larger family-sized packs, this production line can accommodate them all.

Another important aspect of the puffed food filling packaging production line is its speed and accuracy. With advanced technology and precision engineering, this system can fill and seal bags at a much faster rate than traditional manual methods. This not only increases productivity but also ensures that each bag is filled with the correct amount of product, reducing waste and improving overall quality control.

Furthermore, the puffed food filling packaging production line is designed to be easy to operate and maintain. With user-friendly interfaces and intuitive controls, operators can quickly learn how to use the system and make adjustments as needed. Additionally, regular maintenance and servicing are straightforward, ensuring that the production line remains in optimal condition for maximum efficiency.

One of the most significant benefits of the puffed food filling packaging production line is its ability to improve product safety and shelf life. By sealing the bags with precision and accuracy, this system helps to protect the puffed food products from contamination and spoilage, extending their shelf life and maintaining their quality for longer periods. This is crucial for manufacturers looking to meet strict food safety standards and deliver fresh, high-quality products to consumers.

Overall, the puffed food filling packaging production line represents a significant advancement in packaging technology for the puffed food industry. With its automated processes, flexibility, speed, and accuracy, this system offers manufacturers a reliable and efficient solution for packaging their products. By investing in this innovative technology, companies can improve their production processes, enhance product quality, and meet the growing demand for puffed food products in the market.