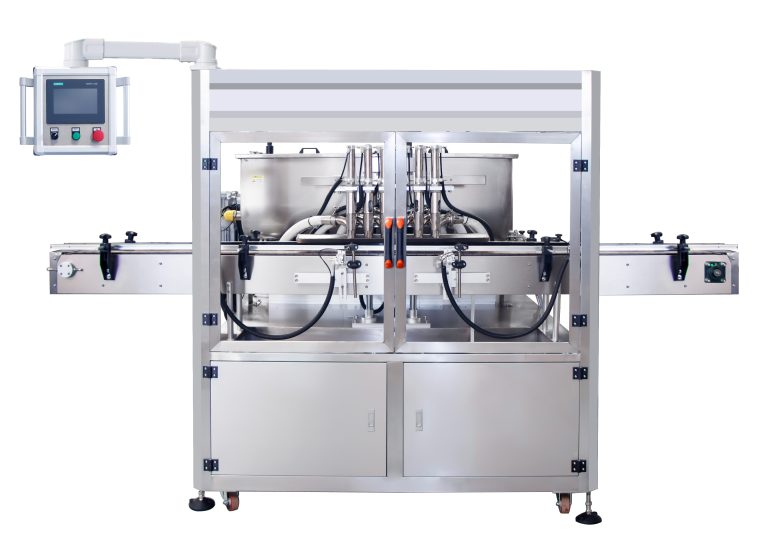

Брак точности и скорости, предлагаемых этими машинами, действительно замечательный. Конфигурация с двойной головкой позволяет им обрабатывать большие объемы заполнения порошка за часть времени, которое это будет принимать с одноголовными машинами. В то же время они сохраняют удивительный уровень точности в измерении и распределении порошка, обеспечивая точное указанное количество.

Этот уровень производительности имеет решающее значение для удовлетворения высоких требований современных потребителей. На рынке, где качество и согласованность не подлежат обсуждению, машины с двойной головкой гарантируют, что продукты достигают полков с единой и надежностью.

Усовершенствованная технология, включенная в эти машины, позволяет легкой интеграции с другими процессами упаковки, создавая оптимизированную и эффективную производственную линию. Их можно точно настроить, чтобы вместить различные плотности порошка и размеры упаковки, обеспечивая гибкость и адаптивность.

Еще одним значительным преимуществом является их способность минимизировать отходы продукта. Точный механизм заполнения уменьшает разлив и переполнение, способствуя экономии затрат и экологической устойчивости.

Кроме того, доминирование машин с двойной порошковой наполнением заключается в их вкладе в повышение производительности и снижение затрат на рабочую силу. С меньшим ручным вмешательством, компании могут более эффективно распределять ресурсы и сосредоточиться на других аспектах операции упаковки.

В заключение, комбинация точности и скорости делает машины с двойной головкой начинки Незаменимый инструмент в современной упаковке. Их способность удовлетворять развивающиеся потребности отрасли и обеспечивать превосходные результаты, поэтому они продолжают формировать будущее упаковки.