Table of Contents

Benefits of Using a Fully Automatic Protein Powder Vacuum Filling Nitrogen Sealing Machine

Protein powder is a popular supplement among fitness enthusiasts and athletes looking to increase their protein intake. With the rise in demand for protein powder products, manufacturers are constantly looking for ways to improve their production processes. One such innovation is the fully automatic protein powder vacuum filling nitrogen sealing machine.

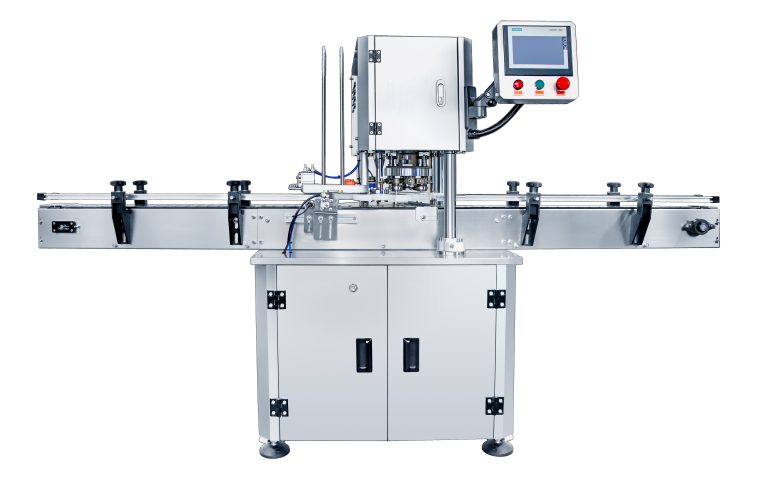

This advanced machine offers a range of benefits for manufacturers looking to streamline their production process and improve the quality of their protein powder products. One of the key advantages of using a fully automatic protein powder vacuum filling nitrogen sealing machine is its efficiency. This machine is designed to fill and seal protein powder containers quickly and accurately, reducing the time and labor required for manual filling and sealing processes.

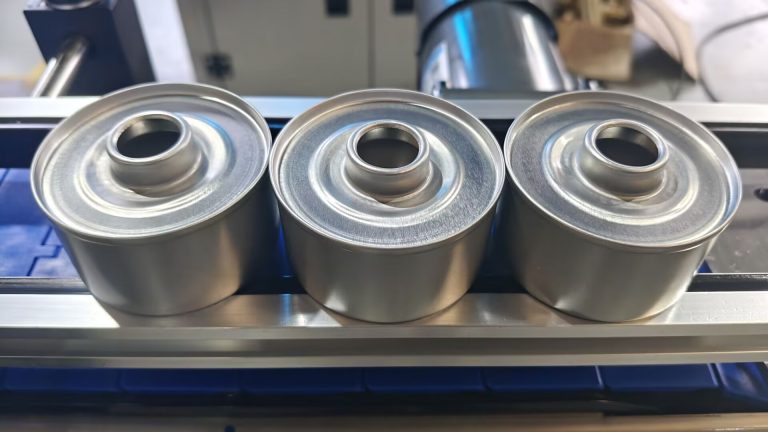

In addition to its efficiency, a fully automatic protein powder vacuum filling nitrogen sealing machine also offers improved accuracy and consistency in filling and sealing protein powder containers. This helps to ensure that each container is filled with the correct amount of protein powder, reducing waste and improving product quality. The nitrogen sealing feature of the machine also helps to preserve the freshness and quality of the protein powder by creating a protective barrier against moisture and oxygen.

Another benefit of using a fully automatic protein powder vacuum filling nitrogen sealing machine is its versatility. This machine is capable of filling and sealing a wide range of container sizes and shapes, making it suitable for use with various types of protein powder products. Whether you are packaging protein powder in jars, bottles, or pouches, this machine can be easily adjusted to accommodate different packaging requirements.

Furthermore, the fully automatic protein powder vacuum filling nitrogen sealing machine is designed to meet strict hygiene and safety standards. The machine is made from high-quality materials that are easy to clean and sanitize, reducing the risk of contamination and ensuring the safety of the product. This is particularly important for manufacturers producing protein powder products for human consumption, as any contamination could pose a health risk to consumers.

In addition to its efficiency, accuracy, versatility, and safety features, a fully automatic protein powder vacuum filling nitrogen sealing machine also offers cost savings for manufacturers. By automating the filling and sealing process, manufacturers can reduce the labor costs associated with manual processes and increase production output. This can help to improve overall efficiency and profitability for protein powder manufacturers.

Overall, the benefits of using a fully automatic protein powder vacuum filling nitrogen sealing machine are clear. From improved efficiency and accuracy to versatility and cost savings, this advanced machine offers a range of advantages for manufacturers looking to enhance their production processes and deliver high-quality protein powder products to consumers. By investing in this innovative technology, manufacturers can stay ahead of the competition and meet the growing demand for protein powder products in the market.

How to Choose the Right Fully Automatic Protein Powder Vacuum Filling Nitrogen Sealing Machine for Your Business

Protein powder is a popular supplement for athletes, bodybuilders, and health-conscious individuals looking to increase their protein intake. With the growing demand for protein powder products, businesses in the health and fitness industry are constantly looking for ways to streamline their production processes. One essential piece of equipment for packaging protein powder is a fully automatic protein powder vacuum filling nitrogen sealing machine.

These machines are designed to efficiently fill containers with protein powder, remove excess air from the packaging, and seal the containers with nitrogen to preserve the freshness and quality of the product. Choosing the right fully automatic protein powder vacuum filling nitrogen sealing machine for your business is crucial to ensuring smooth and efficient production processes.

When selecting a fully automatic protein powder vacuum filling nitrogen sealing machine, there are several factors to consider. First and foremost, you need to assess the production capacity of the machine. Depending on the size of your business and the volume of protein powder products you produce, you will need to choose a machine that can meet your production needs. Look for machines that can fill and seal containers at a high speed without compromising on accuracy and quality.

Another important factor to consider is the versatility of the machine. Some fully automatic protein powder vacuum filling nitrogen sealing machines are designed to work with a variety of container sizes and shapes, while others are more limited in their capabilities. If you plan on packaging protein powder in different types of containers, make sure to choose a machine that can accommodate your specific packaging requirements.

In addition to production capacity and versatility, it is essential to consider the level of automation of the machine. Fully automatic machines are equipped with advanced technology that allows them to operate with minimal human intervention. These machines are ideal for businesses looking to increase efficiency and reduce labor costs. However, if you prefer more control over the packaging process, you may opt for a semi-automatic machine that requires some manual input.

Furthermore, when choosing a fully automatic protein powder vacuum filling nitrogen sealing machine, it is important to consider the quality and reliability of the machine. Look for machines from reputable manufacturers with a track record of producing high-quality equipment. Read reviews and testimonials from other businesses in the industry to gauge the performance and durability of the machine.

Lastly, consider the after-sales support and maintenance services offered by the manufacturer. A fully automatic protein powder vacuum filling nitrogen sealing machine is a significant investment for your business, so it is crucial to choose a manufacturer that provides excellent customer service and technical support. Make sure to inquire about warranty coverage, spare parts availability, and maintenance services to ensure that your machine operates smoothly and efficiently.

In conclusion, choosing the right fully automatic protein powder vacuum filling nitrogen sealing machine for your business is a critical decision that can impact the efficiency and productivity of your production processes. Consider factors such as production capacity, versatility, automation level, quality, and after-sales support when selecting a machine. By investing in a high-quality and reliable machine, you can streamline your packaging processes and meet the growing demand for protein powder products in the market.

Maintenance Tips for Ensuring Optimal Performance of a Fully Automatic Protein Powder Vacuum Filling Nitrogen Sealing Machine

Protein powder is a popular supplement for athletes and fitness enthusiasts looking to increase their protein intake. To meet the demand for this product, many manufacturers use fully automatic protein powder vacuum filling nitrogen sealing machines to efficiently package the powder. These machines are designed to accurately fill containers with protein powder, remove air from the packaging, and seal the containers with nitrogen to preserve the freshness of the product.

To ensure that a fully automatic protein powder vacuum filling nitrogen sealing machine operates at optimal performance, regular maintenance is essential. Proper maintenance not only extends the lifespan of the machine but also helps to prevent breakdowns and costly repairs. In this article, we will discuss some maintenance tips to keep your machine running smoothly.

First and foremost, it is important to regularly clean the machine to prevent the buildup of protein powder residue. Over time, residue can accumulate on the filling nozzles, conveyor belts, and other components of the machine, leading to clogs and malfunctions. To clean the machine, use a mild detergent and warm water to remove any residue. Be sure to dry the machine thoroughly before using it again to prevent rusting.

In addition to cleaning, it is important to regularly inspect the machine for any signs of wear and tear. Check for loose or damaged parts, such as belts, seals, and gaskets, and replace them as needed. Regular inspections can help to identify potential issues before they escalate into major problems.

Another important maintenance tip is to lubricate the moving parts of the machine regularly. Proper lubrication helps to reduce friction and wear on the components, extending their lifespan. Use a high-quality lubricant recommended by the manufacturer and follow the instructions for application.

It is also important to calibrate the machine regularly to ensure accurate filling and sealing of containers. Improper calibration can result in underfilled or overfilled containers, leading to product waste and customer dissatisfaction. Follow the manufacturer’s guidelines for calibration and make adjustments as needed.

Regularly check the nitrogen supply to the machine to ensure that it is functioning properly. Nitrogen is used to create a protective atmosphere inside the containers, preventing oxidation and preserving the freshness of the protein powder. If the nitrogen supply is low or not working, the quality of the product may be compromised.

Lastly, it is important to train your staff on proper machine operation and maintenance procedures. Ensure that all operators are familiar with the machine’s functions and know how to perform routine maintenance tasks. Proper training can help to prevent accidents and ensure that the machine is used correctly.

In conclusion, regular maintenance is essential for ensuring optimal performance of a fully automatic protein powder vacuum filling nitrogen sealing machine. By following these maintenance tips, you can extend the lifespan of your machine, prevent breakdowns, and ensure that your protein powder is packaged efficiently and accurately. Remember to clean the machine regularly, inspect for wear and tear, lubricate moving parts, calibrate the machine, check the nitrogen supply, and train your staff on proper operation and maintenance procedures. With proper maintenance, your machine will continue to operate smoothly and efficiently for years to come.