Table of Contents

Benefits of Using a Fully Automatic Capper Machine for Screw Caps

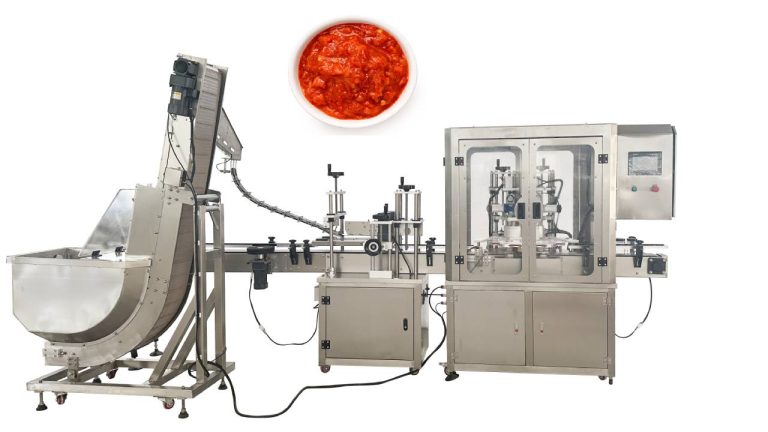

In the manufacturing industry, efficiency and precision are key factors in ensuring the success of a production line. One crucial aspect of this process is the sealing of products with screw caps, which requires a high level of accuracy to prevent leaks and contamination. This is where fully automatic capper machines come into play, offering a range of benefits that can significantly improve the efficiency and quality of the sealing process.

One of the primary advantages of using a fully automatic capper machine for screw caps is the speed at which it can operate. These machines are designed to cap bottles or containers at a much faster rate than manual labor, allowing for higher production output in a shorter amount of time. This increased speed not only boosts productivity but also reduces labor costs, as fewer workers are needed to complete the same task.

Furthermore, fully automatic capper machines are equipped with advanced technology that ensures consistent and precise capping. This level of accuracy is crucial in maintaining the integrity of the product and preventing any leaks or contamination. By eliminating human error, these machines can guarantee a tight and secure seal on every bottle, resulting in a higher quality end product.

Another benefit of using a fully automatic capper machine is the versatility it offers in terms of cap sizes and types. These machines can be easily adjusted to accommodate different screw cap sizes, allowing for greater flexibility in production. Whether you are sealing small vials or large containers, a fully automatic capper machine can handle a wide range of cap sizes with ease.

In addition to speed and precision, fully automatic capper machines also offer a higher level of safety in the production process. By automating the capping process, workers are less exposed to potential hazards such as repetitive strain injuries or accidents caused by manual handling of heavy caps. This not only improves the overall safety of the workplace but also reduces the risk of costly downtime due to injuries.

Furthermore, fully automatic capper machines are designed to be user-friendly and easy to operate. With intuitive controls and minimal maintenance requirements, these machines can be seamlessly integrated into existing production lines without causing disruptions. This ease of use allows for a smooth transition to automated capping, saving time and resources in the long run.

Overall, the benefits of using a fully automatic capper machine for screw caps are clear. From increased speed and precision to improved safety and versatility, these machines offer a range of advantages that can significantly enhance the efficiency and quality of the sealing process. By investing in a fully automatic capper machine, manufacturers can streamline their production lines, reduce costs, and ultimately deliver a superior end product to their customers.

How to Choose the Right Fully Automatic Capper Machine for Screw Caps

Fully automatic capper machines for screw caps are essential equipment for industries that require efficient and precise sealing of bottles and containers. These machines are designed to streamline the capping process, ensuring that each cap is securely fastened onto the container with minimal human intervention. With the advancement of technology, fully automatic capper machines have become more sophisticated, offering a wide range of features to meet the diverse needs of different industries.

When choosing the right fully automatic capper machine for screw caps, there are several factors to consider. One of the most important factors is the speed and efficiency of the machine. The capper machine should be able to cap a large number of bottles or containers per minute to keep up with the production demands of the industry. Additionally, the machine should be able to handle different sizes and types of screw caps to accommodate the variety of products being packaged.

Another important factor to consider is the accuracy and precision of the capping process. The fully automatic capper machine should be able to consistently apply the right amount of torque to each cap to ensure a secure seal without damaging the cap or the container. This is especially important for industries that require a high level of quality control and consistency in their packaging process.

In addition to speed and accuracy, it is also important to consider the ease of use and maintenance of the fully automatic capper machine. The machine should be user-friendly, with intuitive controls and easy setup procedures. It should also be easy to clean and maintain to ensure optimal performance and longevity.

Furthermore, it is important to consider the overall reliability and durability of the fully automatic capper machine. The machine should be built with high-quality materials and components to withstand the rigors of continuous use in an industrial setting. It should also be backed by a reliable manufacturer with a reputation for producing reliable and durable equipment.

When choosing a fully automatic capper machine for screw caps, it is also important to consider the level of customization and flexibility offered by the machine. Some machines come with adjustable settings and interchangeable parts to accommodate different types of caps and containers. This flexibility can be crucial for industries that package a wide range of products with varying cap sizes and styles.

In conclusion, choosing the right fully automatic capper machine for screw caps is essential for industries that require efficient and precise capping of bottles and containers. By considering factors such as speed, accuracy, ease of use, reliability, and flexibility, businesses can select a machine that meets their specific needs and helps streamline their packaging process. With the right fully automatic capper machine, businesses can improve their production efficiency, reduce labor costs, and ensure consistent quality in their packaging operations.

Maintenance Tips for Fully Automatic Capper Machines for Screw Caps

Fully automatic capper machines for screw caps are essential equipment in many industries, including food and beverage, pharmaceuticals, and cosmetics. These machines are designed to efficiently and accurately apply screw caps to bottles or containers, ensuring a tight seal and preventing leakage or contamination. To ensure the smooth operation and longevity of your fully automatic capper machine, regular maintenance is crucial.

One of the most important maintenance tasks for a fully automatic capper machine is cleaning. Over time, dust, debris, and product residue can build up on the machine’s components, leading to decreased efficiency and potential malfunctions. It is recommended to clean the machine regularly, following the manufacturer’s guidelines for the specific model. This may involve disassembling certain parts for thorough cleaning and reassembling them properly.

In addition to cleaning, lubrication is another key aspect of maintaining a fully automatic capper machine. Proper lubrication helps reduce friction between moving parts, preventing wear and tear and ensuring smooth operation. It is important to use the correct type of lubricant recommended by the manufacturer and to apply it to the designated areas at regular intervals.

Regular inspection of the machine’s components is also essential for detecting any signs of wear or damage early on. This includes checking for loose or worn parts, misaligned components, and any unusual noises or vibrations during operation. Any issues should be addressed promptly to prevent further damage and ensure the machine’s optimal performance.

Calibration is another important maintenance task for fully automatic capper machines. Over time, the machine’s settings may drift, affecting the accuracy and consistency of cap application. Regular calibration ensures that the machine is operating within the specified parameters, resulting in reliable and precise performance.

In addition to these routine maintenance tasks, it is important to schedule periodic professional inspections and servicing of the fully automatic capper machine. A trained technician can identify and address any potential issues that may not be apparent during regular maintenance, helping to prevent costly repairs or downtime in the future.

Proper training of operators is also crucial for the efficient and safe operation of a fully automatic capper machine. Operators should be familiar with the machine’s functions, safety protocols, and maintenance procedures to ensure smooth operation and prevent accidents or damage.

In conclusion, regular maintenance is essential for ensuring the optimal performance and longevity of a fully automatic capper machine for screw caps. By following the manufacturer’s guidelines, cleaning, lubricating, inspecting, calibrating, and servicing the machine regularly, you can prevent malfunctions, extend its lifespan, and maintain high-quality production standards. Proper training of operators is also key to safe and efficient operation. By investing time and effort in maintenance, you can maximize the efficiency and reliability of your fully automatic capper machine, ultimately benefiting your business and customers.