Table of Contents

Sustainable Packaging Solutions for Cookie Manufacturers

In recent years, there has been a growing demand for sustainable packaging solutions in the food industry. Cookie manufacturers are no exception, as consumers are becoming more conscious of the environmental impact of their purchases. One innovative solution that has gained popularity is the use of paper cans for packaging cookies.

Paper cans are a sustainable alternative to traditional plastic packaging, as they are made from renewable resources and are biodegradable. This makes them an attractive option for cookie manufacturers looking to reduce their carbon footprint and appeal to eco-conscious consumers. In addition, paper cans can be easily recycled, further reducing their environmental impact.

One of the key benefits of using paper cans for cookie packaging is their versatility. Paper cans come in a variety of sizes and shapes, making them suitable for packaging a wide range of cookie products. Whether you are selling individual cookies or larger packs, paper cans can be customized to meet your specific packaging needs.

Another advantage of paper cans is their durability. Despite being made from paper, these cans are sturdy and can protect cookies from damage during shipping and handling. This ensures that your products arrive in perfect condition, maintaining their quality and freshness for consumers to enjoy.

When it comes to branding and marketing, paper cans offer a unique and eye-catching packaging solution. With the ability to print custom designs and logos on the cans, cookie manufacturers can create a distinctive and memorable packaging that sets their products apart from the competition. This can help attract consumers and build brand loyalty, ultimately driving sales and growth for the business.

Transitioning to a paper can packaging line for cookies may require some initial investment, but the long-term benefits far outweigh the costs. Not only does it demonstrate a commitment to sustainability and environmental responsibility, but it also aligns with consumer preferences for eco-friendly products. By making the switch to paper cans, cookie manufacturers can enhance their brand image, attract new customers, and contribute to a more sustainable future.

In conclusion, paper cans offer a sustainable packaging solution for cookie manufacturers looking to reduce their environmental impact and meet consumer demand for eco-friendly products. With their versatility, durability, and branding potential, paper cans are an attractive option for packaging cookies of all shapes and sizes. By making the switch to paper cans, cookie manufacturers can differentiate their products in the market, appeal to environmentally conscious consumers, and drive growth for their business. Embracing sustainable packaging solutions like paper cans is not only good for the planet but also for the bottom line.

How to Optimize Efficiency in Cookie Packaging Lines with Paper Cans

In the world of food packaging, efficiency is key. Cookie manufacturers are constantly looking for ways to optimize their packaging lines to increase productivity and reduce costs. One innovative solution that has gained popularity in recent years is the use of paper cans for cookie packaging. Paper cans offer a number of benefits, including sustainability, versatility, and cost-effectiveness. In this article, we will explore how cookie manufacturers can optimize efficiency in their packaging lines by using paper cans.

One of the main advantages of using paper cans for cookie packaging is their sustainability. Paper cans are made from renewable resources and are biodegradable, making them a more environmentally friendly option compared to traditional plastic packaging. By using paper cans, cookie manufacturers can appeal to environmentally conscious consumers and reduce their carbon footprint. Additionally, paper cans can be easily recycled, further reducing the environmental impact of cookie packaging.

Another benefit of paper cans is their versatility. Paper cans come in a variety of sizes and shapes, allowing cookie manufacturers to customize their packaging to meet the specific needs of their products. Whether manufacturers are packaging small cookies for individual servings or larger cookies for sharing, paper cans can accommodate a wide range of sizes. This versatility allows manufacturers to streamline their packaging process and reduce waste by using the most appropriate packaging for each product.

In addition to sustainability and versatility, paper cans are also cost-effective. Paper cans are typically less expensive than plastic packaging, making them an attractive option for cookie manufacturers looking to reduce packaging costs. By using paper cans, manufacturers can lower their overall packaging expenses without sacrificing quality or functionality. This cost savings can be passed on to consumers, making paper cans a win-win solution for both manufacturers and customers.

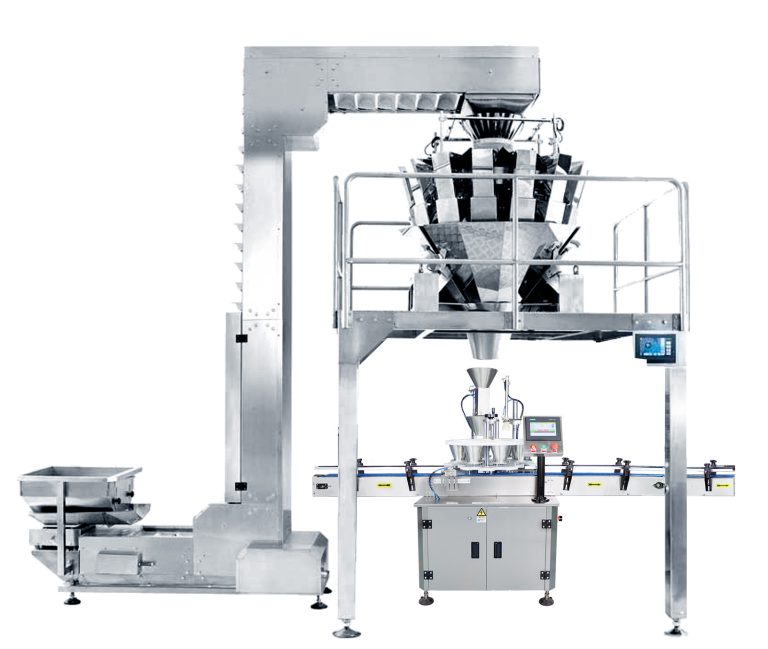

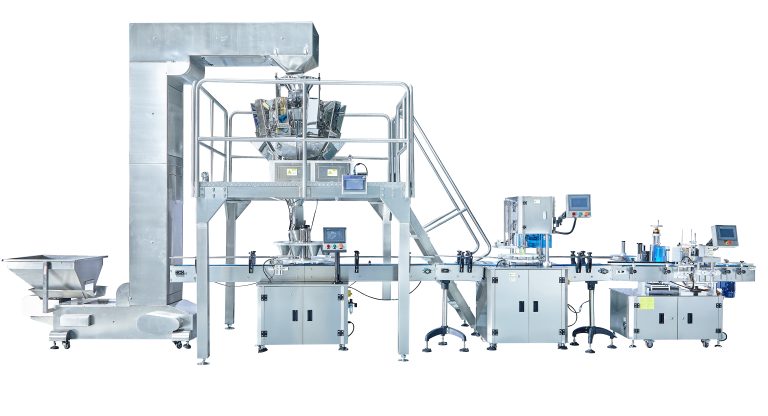

To optimize efficiency in cookie packaging lines with paper cans, manufacturers should consider implementing a few key strategies. First, manufacturers should invest in high-quality paper can packaging equipment. This equipment should be able to handle a variety of can sizes and shapes, as well as accommodate high-speed production lines. By investing in reliable equipment, manufacturers can ensure that their packaging process runs smoothly and efficiently.

Second, manufacturers should streamline their packaging process by implementing automation wherever possible. Automated packaging equipment can significantly increase efficiency by reducing the need for manual labor and minimizing the risk of errors. By automating tasks such as filling, sealing, and labeling paper cans, manufacturers can speed up their packaging process and increase overall productivity.

Finally, manufacturers should prioritize quality control to ensure that their paper cans meet the highest standards. By implementing rigorous quality control measures, manufacturers can minimize the risk of defects or contamination in their packaging, ensuring that their products reach consumers in perfect condition. By maintaining high quality standards, manufacturers can build trust with consumers and enhance their brand reputation.

In conclusion, paper cans offer a sustainable, versatile, and cost-effective solution for cookie packaging. By optimizing efficiency in cookie packaging lines with paper cans, manufacturers can reduce costs, increase productivity, and improve overall quality. By investing in high-quality equipment, automating processes, and prioritizing quality control, manufacturers can take full advantage of the benefits of paper cans and enhance their packaging operations.