Automatic Double-Head Servo Capping Machines operate through a series of precise and coordinated steps.

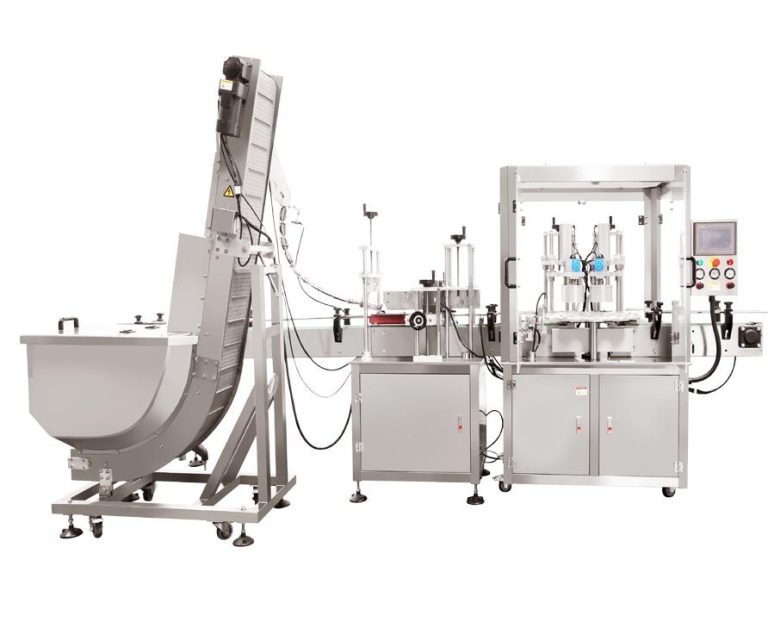

First, the containers to be capped are fed into the machine in an organized manner, often via a conveyor system. At the same time, the screw caps are also supplied to the machine in a controlled manner.

The machine’s sensors detect the presence and position of the containers. Once a container is in the correct position, the two capping heads simultaneously descend and engage with the caps.

The servo system comes into play, precisely controlling the rotational speed and torque applied to the caps. This ensures that the caps are screwed onto the containers with the exact amount of force and tightness needed for a secure seal.

Throughout the process, advanced monitoring systems keep track of the capping operation. If any issues arise, such as a misaligned cap or a container not in the correct position, the machine will either correct the problem or stop the operation to prevent faulty capping.

Once the caps are properly applied, the capped containers are moved along the conveyor for further processing or packaging.

The entire process is highly automated and efficient, allowing for a rapid and consistent capping of a large number of containers in a short period of time.