Table of Contents

Piston Filling Machines

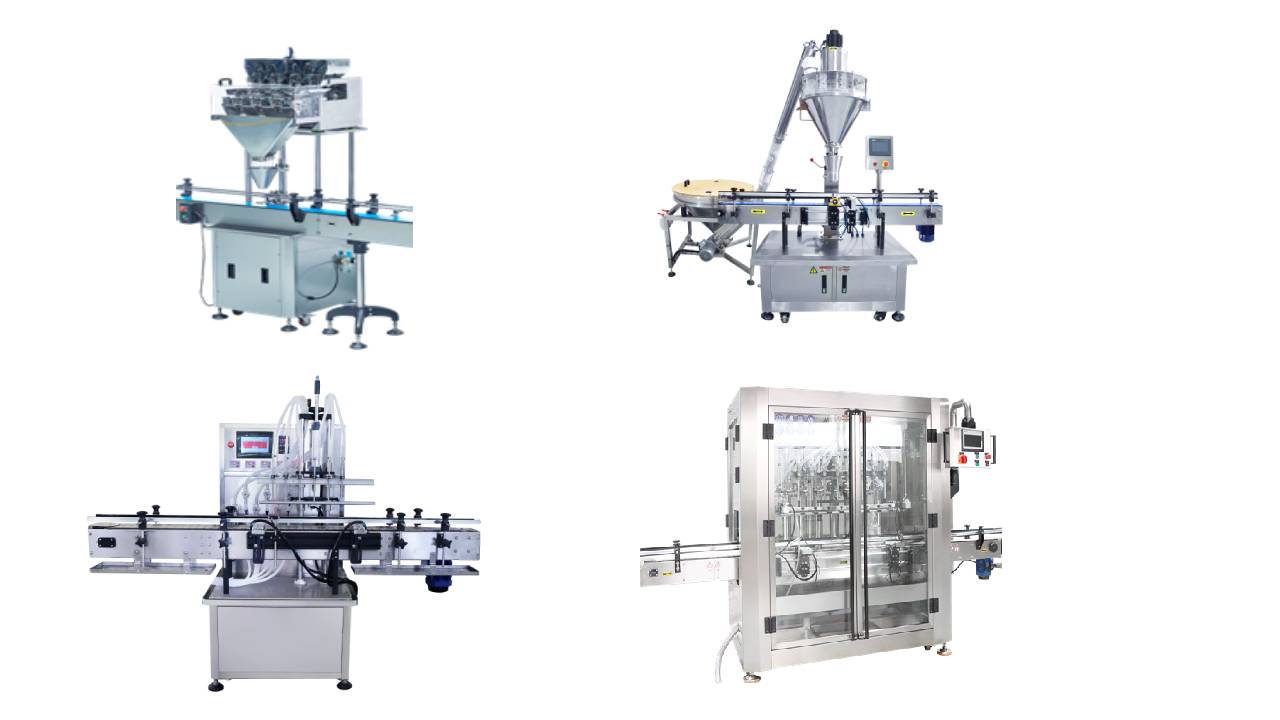

Filling machines are essential equipment in various industries, including food and beverage, pharmaceuticals, cosmetics, and more. These machines are designed to accurately fill containers with liquid or semi-liquid products, ensuring efficiency and consistency in the production process. One common type of filling machine is the piston filling machine, which operates using a piston mechanism to dispense the product into containers.

Piston filling machines are versatile and can handle a wide range of products, from thin liquids like water and juice to thick pastes like peanut butter and lotion. The key component of a piston filling machine is the piston itself, which moves up and down within a cylinder to draw in and dispense the product. The size of the piston can be adjusted to accommodate different fill volumes, making these machines suitable for various packaging requirements.

One of the main advantages of piston filling machines is their accuracy and precision. The piston mechanism allows for precise control over the fill volume, ensuring that each container is filled to the exact specifications. This is especially important in industries where consistency is crucial, such as pharmaceuticals and cosmetics. Additionally, piston filling machines are relatively easy to clean and maintain, making them a practical choice for manufacturers looking to streamline their production process.

There are several variations of piston filling machines available, each designed to meet specific needs and requirements. For example, single-head piston fillers are ideal for small-scale production or when filling multiple products with different viscosities. These machines can be easily adjusted to accommodate different products and fill volumes, making them a versatile option for manufacturers with diverse product lines.

On the other hand, multi-head piston fillers are suitable for high-speed production lines that require rapid filling of multiple containers simultaneously. These machines feature multiple pistons operating in sync to fill containers quickly and efficiently. Multi-head piston fillers are commonly used in industries with high production volumes, such as bottling plants and packaging facilities.

In addition to single-head and multi-head piston fillers, there are also rotary piston fillers that combine the benefits of piston filling with the efficiency of rotary technology. These machines feature a rotating carousel with multiple pistons that move in a circular motion to fill containers as they pass through the machine. Rotary piston fillers are ideal for high-speed production lines that require precise filling and sealing of containers.

Overall, piston filling machines are a reliable and efficient solution for manufacturers looking to streamline their production process and ensure consistent product quality. With various types of piston fillers available, manufacturers can choose the machine that best suits their needs and requirements. Whether it’s a single-head piston filler for small-scale production or a multi-head rotary piston filler for high-speed lines, piston filling machines offer versatility, accuracy, and efficiency in filling containers with liquid and semi-liquid products.

Overflow Filling Machines

Filling machines are essential equipment in various industries, including food and beverage, pharmaceuticals, and cosmetics. These machines are designed to accurately fill containers with liquid products, ensuring efficiency and consistency in production. One type of filling machine that is commonly used in the industry is the overflow filling machine.

Overflow filling machines are ideal for filling containers with foamy or viscous liquids, as they use a unique filling method to achieve precise and consistent fills. These machines work by filling the container to the brim, allowing the excess liquid to overflow into a reservoir. This ensures that each container is filled to the same level, regardless of variations in viscosity or foaminess.

One of the key advantages of overflow filling machines is their ability to fill containers with a wide range of shapes and sizes. This versatility makes them a popular choice for manufacturers who produce a variety of products in different packaging formats. Additionally, overflow filling machines are known for their high filling accuracy, making them suitable for products that require precise fill levels.

Another benefit of overflow filling machines is their gentle handling of products. The overflow filling method minimizes splashing and foaming, which helps to maintain the integrity of the product and reduce waste. This is particularly important for delicate or expensive products that require careful handling during the filling process.

In terms of operation, overflow filling machines are relatively easy to set up and operate. They can be adjusted to accommodate different fill volumes and speeds, allowing manufacturers to customize the filling process to meet their specific production requirements. Additionally, overflow filling machines are designed for easy cleaning and maintenance, ensuring optimal performance and longevity.

There are several variations of overflow filling machines available on the market, each designed to meet specific production needs. For example, some overflow filling machines are equipped with multiple filling heads to increase production speed, while others are designed for filling containers with narrow openings or irregular shapes. Manufacturers can choose the type of overflow filling machine that best suits their production requirements and budget.

Overall, overflow filling machines are a versatile and efficient solution for filling containers with foamy or viscous liquids. Their unique filling method ensures accuracy and consistency in production, while their gentle handling of products helps to maintain product quality. With various options available on the market, manufacturers can find an overflow filling machine that meets their specific production needs and enhances their overall efficiency.

Gravity Filling Machines

Filling machines are essential equipment in various industries, including food and beverage, pharmaceuticals, and cosmetics. These machines are designed to accurately fill containers with liquid or semi-liquid products, ensuring consistency and efficiency in the production process. One common type of filling machine is the gravity filling machine, which operates based on the principle of gravity.

Gravity filling machines are widely used in industries where the products being filled have low to medium viscosity. These machines are simple in design and operation, making them a cost-effective solution for many manufacturers. Gravity filling machines work by using the force of gravity to fill containers with the desired product. The product is fed into a holding tank, which is then connected to a filling nozzle. As the containers pass under the filling nozzle, the product flows down into the containers due to gravity.

One of the key advantages of gravity filling machines is their versatility. These machines can handle a wide range of container sizes and shapes, making them suitable for various products. Additionally, gravity filling machines are easy to set up and adjust, allowing manufacturers to quickly switch between different products or container sizes. This flexibility is particularly beneficial for companies that produce a variety of products or have changing production requirements.

Gravity filling machines are also known for their high filling accuracy. The design of these machines ensures that the product is dispensed consistently into each container, minimizing waste and ensuring product quality. This level of accuracy is crucial for industries where precise filling is essential, such as pharmaceuticals or cosmetics.

Another advantage of gravity filling machines is their gentle handling of products. Since these machines rely on gravity to fill containers, there is minimal agitation or foaming of the product. This gentle filling process helps preserve the integrity of the product, particularly for delicate or sensitive products. Additionally, gravity filling machines are suitable for filling products with particulates or chunks, as the product can flow freely without being forced through the filling nozzle.

In terms of maintenance, gravity filling machines are relatively easy to clean and maintain. The simple design of these machines means that there are fewer moving parts that can wear out or break down. Regular cleaning and maintenance of the filling nozzles and hoses are typically all that is required to keep a gravity filling machine running smoothly. This ease of maintenance helps minimize downtime and ensures consistent production output.

In conclusion, gravity filling machines are a popular choice for many manufacturers due to their simplicity, versatility, accuracy, and gentle handling of products. These machines offer a cost-effective solution for filling containers with liquid or semi-liquid products and are suitable for a wide range of industries. With their high filling accuracy and ease of maintenance, gravity filling machines are an essential piece of equipment for companies looking to streamline their production processes and ensure product quality.