Table of Contents

Efficiency and Speed

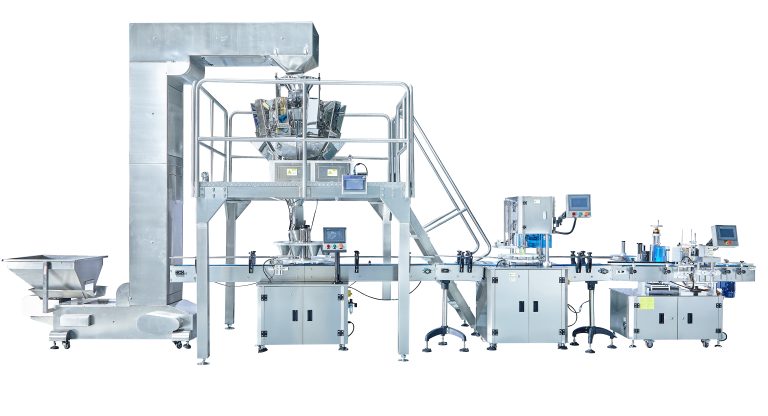

When it comes to choosing an automatic can sealing machine for your production line, efficiency and speed are two key factors to consider. These features can greatly impact the overall productivity and output of your operation. In this article, we will discuss some of the best features to look for in an automatic can sealing machine that can help improve efficiency and speed.

One of the most important features to consider when looking for an automatic can sealing machine is its sealing speed. The speed at which the machine can seal cans can have a significant impact on the overall productivity of your operation. Look for a machine that offers high sealing speeds to ensure that your production line can keep up with demand.

-scaled.jpg)

In addition to sealing speed, it is also important to consider the efficiency of the machine. Look for a machine that is designed to minimize downtime and maximize output. Features such as automatic can feeding and ejection can help streamline the sealing process and improve overall efficiency.

Another important feature to look for in an automatic can sealing machine is its sealing accuracy. A machine that can consistently produce a tight and secure seal on each can is essential for maintaining product quality and preventing leaks or contamination. Look for a machine that offers precise sealing mechanisms and adjustable settings to ensure that each can is sealed correctly.

Ease of use is another important factor to consider when choosing an automatic can sealing machine. Look for a machine that is user-friendly and easy to operate. Features such as intuitive controls, quick changeover capabilities, and easy maintenance procedures can help streamline the sealing process and reduce the risk of errors or downtime.

Durability and reliability are also key features to look for in an automatic can sealing machine. Choose a machine that is built to last and can withstand the rigors of continuous use. Look for machines that are constructed from high-quality materials and feature robust components to ensure long-term reliability.

Finally, consider the overall footprint and layout of the machine. Choose a machine that is compact and space-efficient to maximize the use of your production floor. Look for machines that can be easily integrated into your existing production line and offer flexibility in terms of placement and configuration.

In conclusion, when looking for an automatic can sealing machine, efficiency and speed are two key features to consider. Look for a machine that offers high sealing speeds, efficiency, accuracy, ease of use, durability, and reliability to ensure that your production line runs smoothly and efficiently. By choosing a machine with these features, you can improve the overall productivity and output of your operation.

Versatility and Compatibility

When it comes to choosing an automatic can sealing machine, there are several key features that you should look for to ensure that you are getting the best possible product for your needs. One of the most important factors to consider is the machine’s versatility and compatibility with different types of cans and lids.

A versatile can sealing machine will be able to handle a wide range of can sizes and shapes, allowing you to seal everything from small cans of spices to large cans of soup. This flexibility is important if you plan on sealing different types of products or if you anticipate changing your product line in the future. Look for a machine that offers adjustable settings for can diameter and height, as well as the ability to switch between different types of lids.

Compatibility is also crucial when choosing a can sealing machine. Make sure that the machine is designed to work with the specific type of cans and lids that you will be using in your production process. Some machines are only compatible with certain sizes or materials of cans, so it is important to check the specifications before making a purchase. Additionally, consider whether the machine is compatible with any existing equipment that you already have in your production line, such as conveyors or labeling machines.

Another important feature to look for in an automatic can sealing machine is ease of use. A user-friendly machine will save you time and frustration during the sealing process, allowing you to focus on other aspects of your production. Look for a machine that offers simple controls and clear instructions for setup and operation. Some machines also come with features like automatic lid feeding and can positioning, which can further streamline the sealing process.

Durability is another key factor to consider when choosing a can sealing machine. Look for a machine that is built to last, with a sturdy construction and high-quality materials. A durable machine will be able to withstand the rigors of daily use in a production environment, reducing the risk of breakdowns and costly repairs. Additionally, consider whether the machine comes with a warranty or service plan to protect your investment.

Finally, consider the speed and efficiency of the can sealing machine. Look for a machine that can seal cans quickly and accurately, allowing you to meet production deadlines and maintain consistent quality. Some machines offer adjustable sealing speeds and pressure settings, allowing you to customize the sealing process to suit your specific needs. Additionally, consider whether the machine offers any additional features that can improve efficiency, such as automatic lid detection or batch counting.

In conclusion, when choosing an automatic can sealing machine, it is important to consider a variety of factors to ensure that you are getting the best possible product for your needs. Look for a machine that is versatile and compatible with different types of cans and lids, as well as easy to use, durable, and efficient. By taking the time to research and compare different machines, you can find the perfect can sealing machine for your production process.