It seems we can’t find what you’re looking for. Perhaps searching can help.

The High Quality Milk Powder Tin Can Filling Machine: Revolutionizing Milk Powder Packaging”

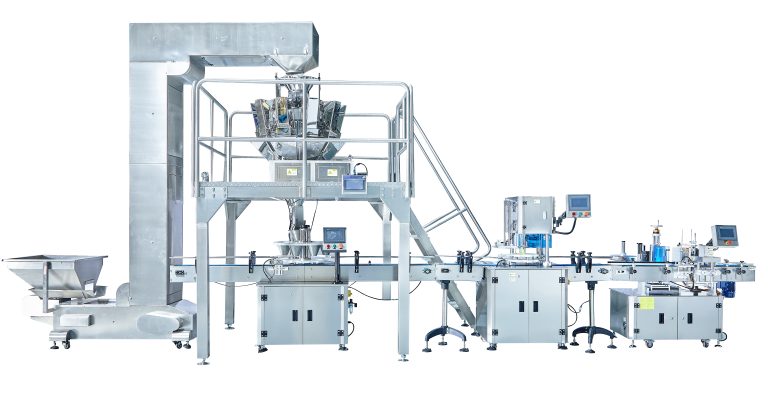

The High Quality Milk Powder Tin Can Filling Machine is a game-changer in the world of milk powder packaging. Let’s explore its exceptional features and the impact it has on the industry. This state-of-the-art machine is meticulously designed to fill milk powder into tin cans with utmost precision and efficiency….