Table of Contents

Benefits of Using Garlic Chili Sauce Filling Vacuum Capping Production Line

Garlic chili sauce is a popular condiment that adds a spicy kick to a variety of dishes. Whether you’re using it as a dipping sauce, marinade, or ingredient in a recipe, having a reliable production line to fill and cap bottles of garlic chili sauce is essential for ensuring efficiency and consistency in your manufacturing process.

One of the key benefits of using a garlic chili sauce filling vacuum capping production line is the speed and accuracy it offers. With automated filling and capping processes, you can significantly increase your production output while maintaining a high level of precision. This means you can meet the demands of your customers more efficiently and reduce the risk of errors in the filling and capping process.

In addition to speed and accuracy, a garlic chili sauce filling vacuum capping production line also helps to improve the overall quality of your product. By using vacuum technology during the filling process, you can remove excess air from the bottles, which helps to preserve the freshness and flavor of the sauce. This results in a longer shelf life for your product and ensures that it reaches consumers in optimal condition.

Furthermore, the capping process is crucial for preventing contamination and ensuring the safety of your product. A vacuum capping system creates a tight seal on the bottles, which helps to prevent leaks and maintain the integrity of the sauce. This not only enhances the quality of your product but also helps to build trust with consumers who expect a reliable and safe product.

Another benefit of using a garlic chili sauce filling vacuum capping production line is the versatility it offers. These production lines can be customized to accommodate different bottle sizes and shapes, allowing you to fill and cap a variety of packaging options. This flexibility is especially useful if you offer different sizes of garlic chili sauce or if you want to expand your product line in the future.

Additionally, a garlic chili sauce filling vacuum capping production line can help to streamline your manufacturing process and reduce labor costs. By automating the filling and capping processes, you can minimize the need for manual labor and free up your employees to focus on other tasks. This not only improves efficiency but also reduces the risk of human error, leading to a more consistent and reliable product.

Overall, investing in a garlic chili sauce filling vacuum capping production line can offer numerous benefits for your manufacturing operation. From increased speed and accuracy to improved quality and safety, these production lines can help you meet the demands of your customers while maintaining a high standard of excellence in your product. With the versatility and efficiency they offer, these production lines are a valuable asset for any company looking to enhance their garlic chili sauce production process.

Step-by-Step Guide to Setting Up a Garlic Chili Sauce Filling Vacuum Capping Production Line

Garlic chili sauce is a popular condiment that adds a spicy kick to a variety of dishes. If you are looking to start a production line for garlic chili sauce filling and vacuum capping, you have come to the right place. In this step-by-step guide, we will walk you through the process of setting up a garlic chili sauce filling vacuum capping production line.

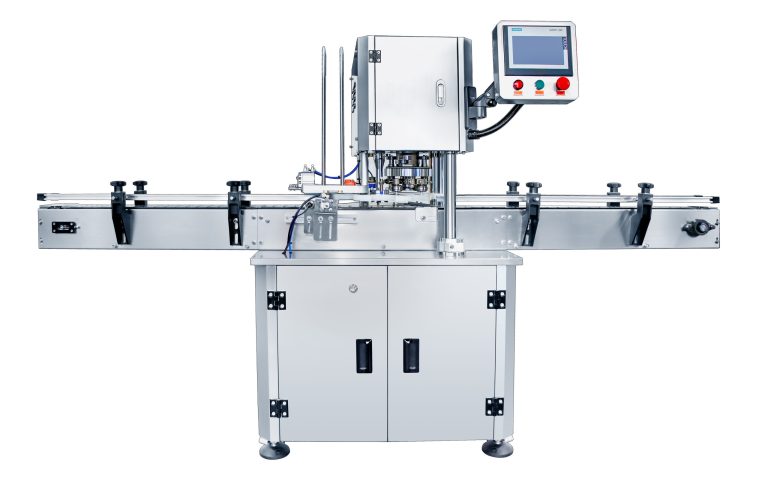

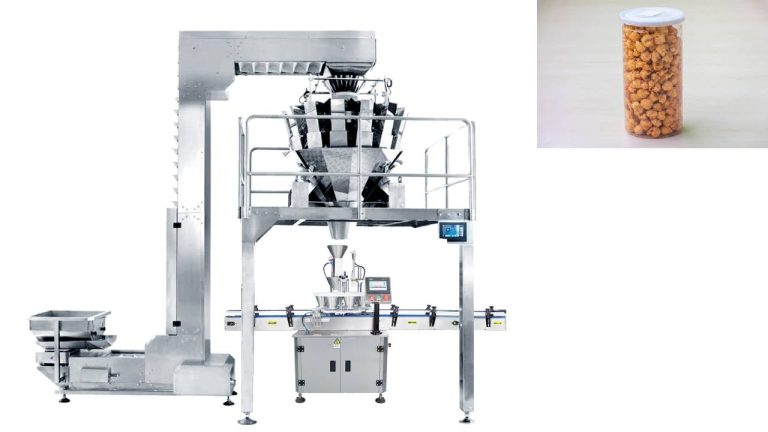

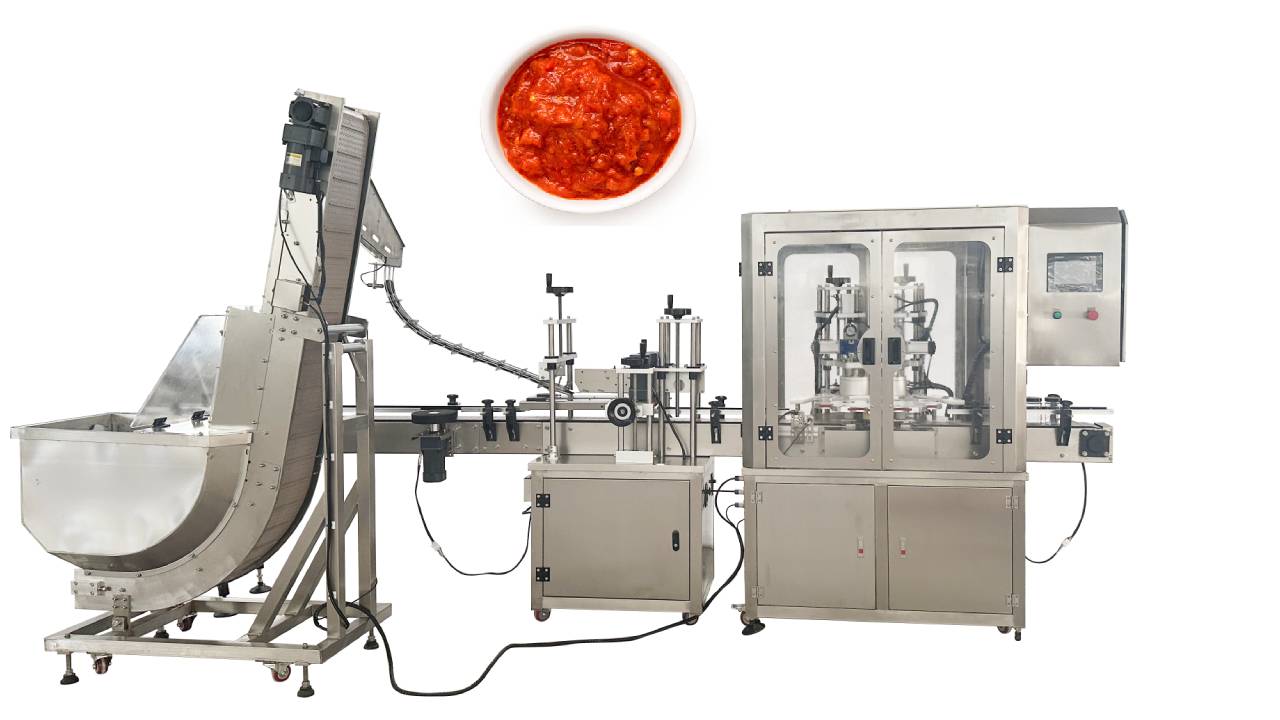

The first step in setting up a garlic chili sauce filling vacuum capping production line is to gather all the necessary equipment. You will need a filling machine, a vacuum capping machine, and containers for the sauce. Make sure to choose equipment that is suitable for filling and capping garlic chili sauce, as it can be thick and chunky.

Once you have all the equipment in place, the next step is to set up the filling machine. This machine will be used to fill the containers with the garlic chili sauce. Make sure to adjust the settings on the machine to accommodate the thickness of the sauce. You may need to test different settings to find the right one.

After the filling machine is set up, it is time to move on to the vacuum capping machine. This machine will be used to seal the containers with the garlic chili sauce. Adjust the settings on the machine to ensure a tight seal on the containers. Again, you may need to test different settings to find the right one.

Once both machines are set up and ready to go, it is time to start the production line. Begin by filling the containers with the garlic chili sauce using the filling machine. Make sure to fill each container to the correct level to avoid spillage.

After the containers are filled, move them to the vacuum capping machine to seal them. Place each container under the capping machine and activate the vacuum seal. The machine will remove the air from the container and seal it tightly with a cap.

Continue this process until all the containers are filled and sealed. Once the production line is up and running smoothly, you can start packaging the garlic chili sauce for distribution.

In conclusion, setting up a garlic chili sauce filling vacuum capping production line requires careful planning and attention to detail. By following this step-by-step guide, you can ensure that your production line runs smoothly and efficiently. With the right equipment and proper setup, you can produce high-quality garlic chili sauce that will delight your customers.