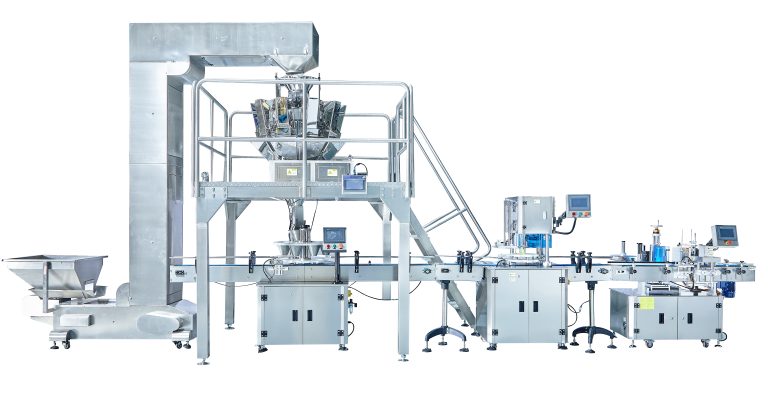

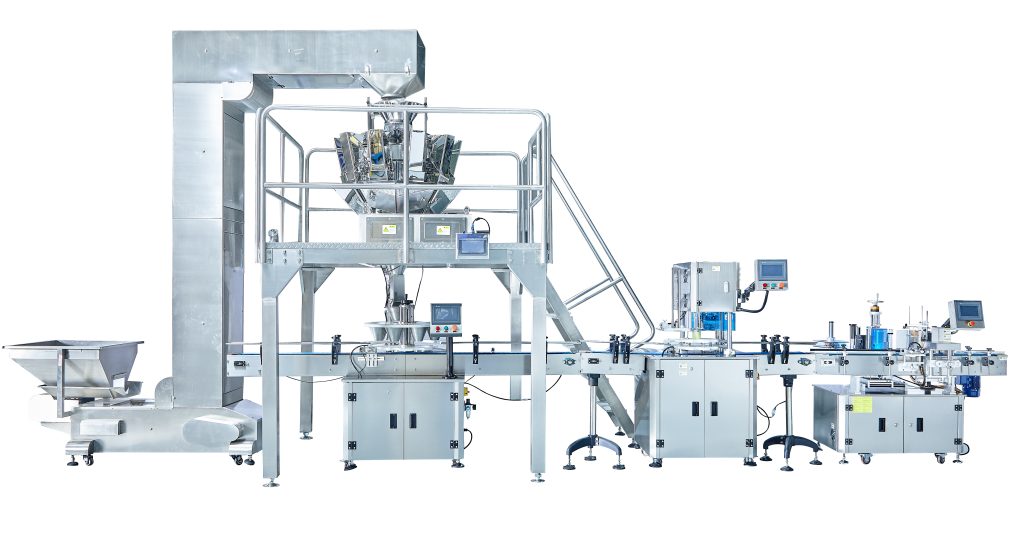

O aspecto de rotulagem deste sistema automático é uma obra -prima da tecnologia. Cada rótulo é aplicado com a colocação exata, garantindo que informações vitais, como detalhes do produto, datas de validade e instruções, sejam exibidas de forma clara e precisa. A impressão de alta resolução e o alinhamento preciso garantem que os rótulos não apenas parecem esteticamente agradáveis, mas também fornecem informações essenciais aos consumidores sem qualquer ambiguidade.

O processo de vedação não é menos impressionante. O mecanismo automático cria um selo hermético que é apertado e uniforme. Isso impede qualquer vazamento ou contaminação, protegendo a qualidade e a segurança dos grânulos enlatados. A precisão na vedação também se estende à capacidade de lidar com diferentes tamanhos e formas com igual proficiência, garantindo uma operação perfeita, independentemente da variação do produto.

Este nível de precisão é alcançado através de uma combinação de sensores avançados, sistemas de controle inteligente e componentes mecânicos finamente ajustados. Esses elementos funcionam em harmonia para monitorar e ajustar os processos de rotulagem e vedação em tempo real, compensando quaisquer pequenas variações nas latas ou nos grânulos.

O resultado é uma solução de embalagem que não apenas atende, mas excede os padrões do setor de qualidade e apresentação. O processo automático de rotulagem e vedação de grânulos enlatados é uma prova do poder da tecnologia moderna de fornecer resultados de embalagens precisos e confiáveis.

Concluindo, explorar a precisão deste sistema automático revela sua contribuição significativa para a eficiência e a qualidade das embalagens de grânulos enlatados, definindo um novo benchmark para excelência no campo.