Table of Contents

Benefits of Using an Automatic Beer Canning Closing Machine

In the world of craft beer production, efficiency and consistency are key factors in ensuring a successful operation. One crucial aspect of the beer canning process is the sealing of the cans after they have been filled with beer. This is where an automatic beer canning closing machine comes into play, offering a range of benefits that can greatly improve the overall production process.

One of the primary benefits of using an automatic beer canning closing machine is the speed at which it can seal cans. These machines are designed to quickly and efficiently seal a large number of cans in a short amount of time, significantly increasing the overall production output. This can be especially beneficial for breweries that are looking to scale up their operations and meet growing demand for their products.

In addition to speed, automatic beer canning closing machines also offer a high level of consistency in the sealing process. Manual sealing can be prone to human error, resulting in inconsistencies in the tightness of the seal or the overall quality of the finished product. By using an automatic machine, breweries can ensure that each can is sealed to the same high standard, reducing the risk of leaks or other issues that can affect the quality of the beer.

Another key benefit of using an automatic beer canning closing machine is the reduction in labor costs. Manual sealing can be a time-consuming and labor-intensive process, requiring skilled workers to carefully seal each can by hand. By automating this process, breweries can free up their employees to focus on other tasks, while also reducing the risk of repetitive strain injuries that can occur from manual sealing.

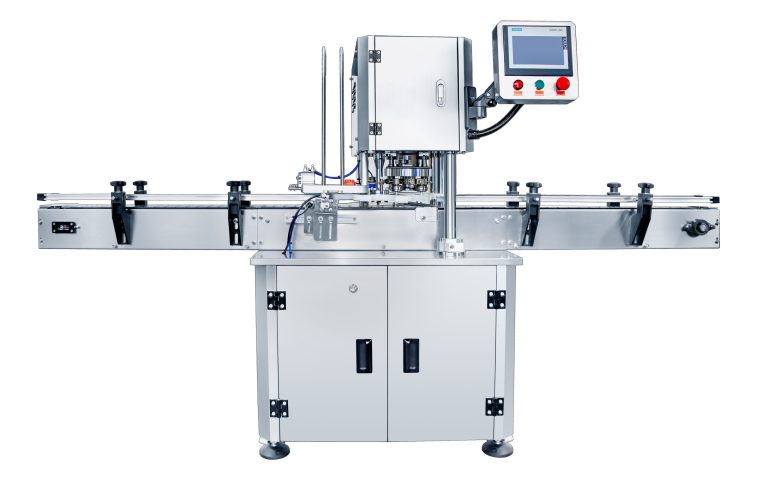

Furthermore, automatic beer canning closing machines are designed to be easy to use and maintain, making them a cost-effective solution for breweries of all sizes. These machines are typically equipped with user-friendly controls and require minimal training to operate, allowing breweries to quickly integrate them into their production process. Additionally, many machines are designed to be durable and long-lasting, reducing the need for frequent repairs or replacements.

In conclusion, the benefits of using an automatic beer canning closing machine are clear. From increased production speed and consistency to reduced labor costs and ease of use, these machines offer a range of advantages that can help breweries improve their overall efficiency and quality. By investing in an automatic machine, breweries can streamline their production process, increase output, and ultimately deliver a better product to their customers.

How to Choose the Right Automatic Beer Canning Closing Machine for Your Brewery

Automatic beer canning closing machines have become an essential piece of equipment for breweries looking to streamline their production process and increase efficiency. With the rise in popularity of canned craft beer, having the right canning machine can make all the difference in meeting consumer demand and maintaining the quality of your product. When it comes to choosing the right automatic beer canning closing machine for your brewery, there are several factors to consider to ensure you make the best investment for your business.

One of the first things to consider when choosing an automatic beer canning closing machine is the speed and capacity of the machine. Depending on the size of your brewery and the volume of beer you produce, you will need to select a machine that can keep up with your production needs. Look for a machine that can handle the volume of cans you plan to fill and close per hour to avoid bottlenecks in your production line.

Another important factor to consider is the size and footprint of the machine. Space is often limited in breweries, so it’s essential to choose a machine that fits comfortably in your production area without causing congestion or hindering workflow. Consider the layout of your brewery and the available space when selecting a canning machine to ensure it integrates seamlessly into your production line.

In addition to speed and size, it’s crucial to consider the quality and reliability of the automatic beer canning closing machine. Look for a machine from a reputable manufacturer with a track record of producing high-quality equipment. A reliable machine will help minimize downtime and maintenance costs, ensuring that your production line runs smoothly and efficiently.

When choosing an automatic beer canning closing machine, it’s also important to consider the level of automation and control features. Some machines offer advanced automation features, such as touch screen controls and programmable settings, that can help streamline the canning process and improve efficiency. Consider your production needs and the level of control you require when selecting a machine to ensure it meets your specific requirements.

Cost is another important factor to consider when choosing an automatic beer canning closing machine for your brewery. While it’s essential to invest in a high-quality machine that meets your production needs, it’s also important to consider your budget and the long-term return on investment. Compare prices from different manufacturers and consider factors such as maintenance costs and energy efficiency when making your decision.

In conclusion, choosing the right automatic beer canning closing machine for your brewery is a crucial decision that can impact the efficiency and quality of your production process. Consider factors such as speed, capacity, size, quality, automation features, and cost when selecting a machine to ensure it meets your specific requirements. By taking the time to research and evaluate your options, you can make an informed decision that will benefit your brewery in the long run.