Table of Contents

Benefits of Using Granules Multi Heads Weighing Filling Machine for Tin Can Packaging

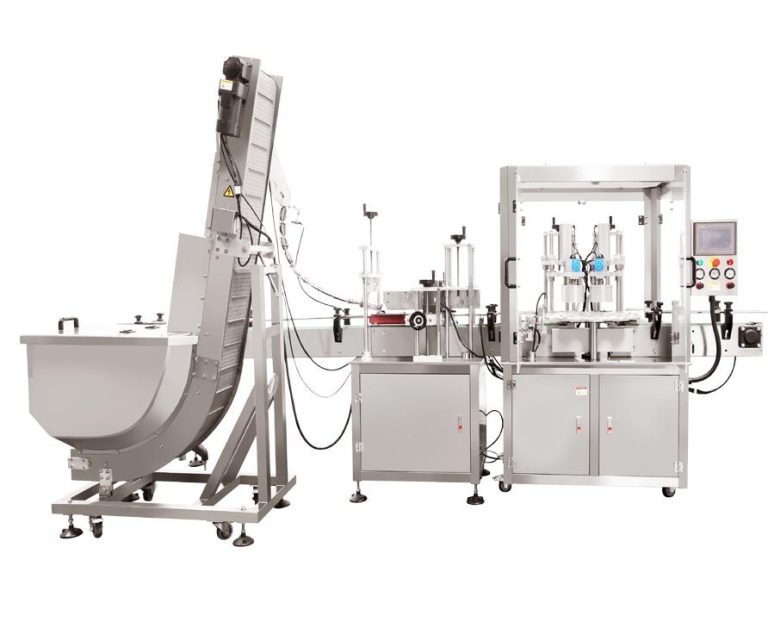

Granules Multi Heads Weighing Filling Machine for Tin Can packaging is a revolutionary technology that offers numerous benefits to businesses in the food and beverage industry. This advanced machine is designed to accurately measure and fill granular products into tin cans, ensuring consistency and efficiency in the packaging process.

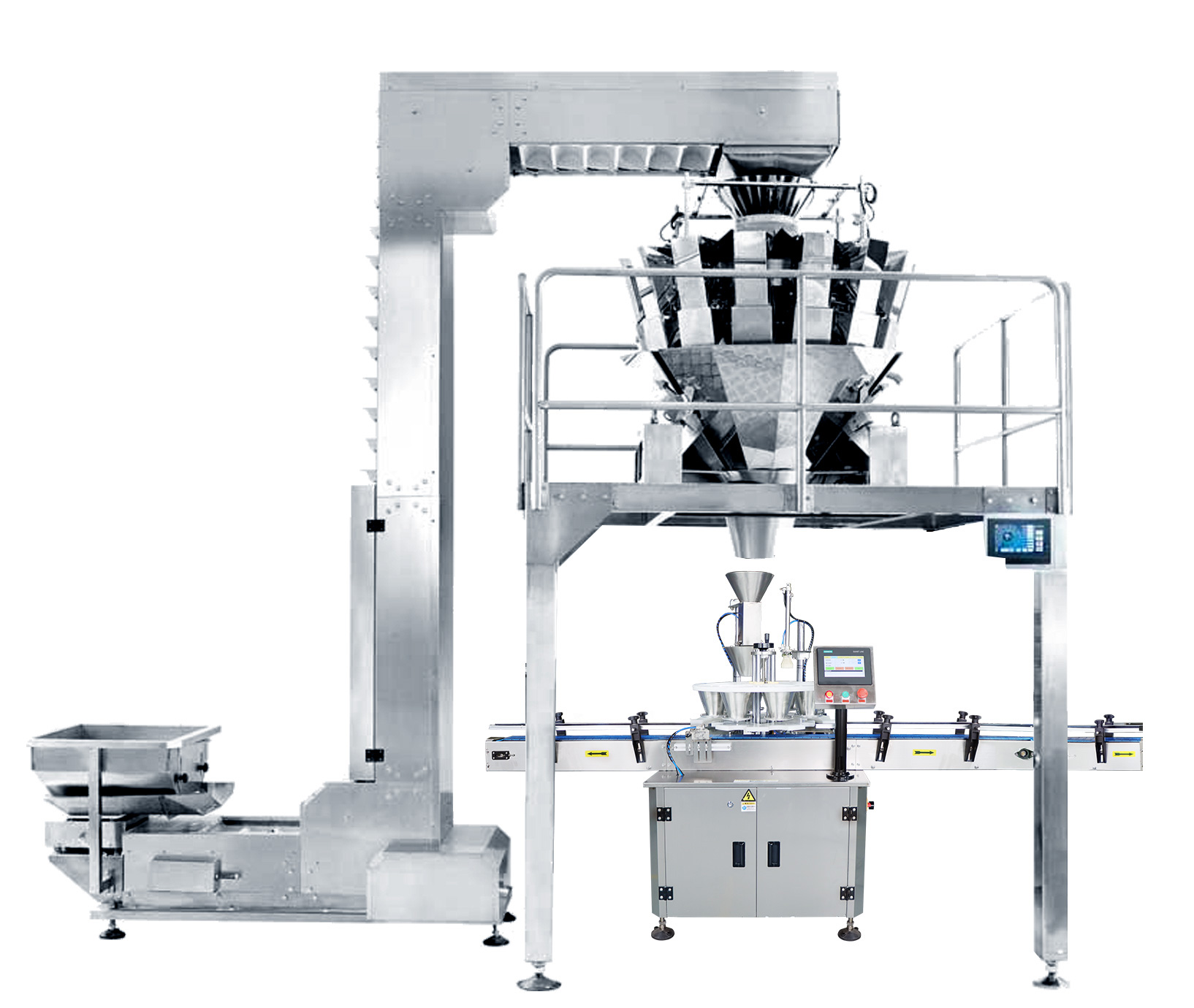

One of the key benefits of using a Granules Multi Heads Weighing Filling Machine is its precision in measuring the exact amount of product to be filled into each tin can. This eliminates the risk of underfilling or overfilling, ensuring that every can is filled to the correct weight. This level of accuracy is crucial for maintaining product quality and meeting regulatory standards.

In addition to precision, the Granules Multi Heads Weighing Filling Machine offers speed and efficiency in the packaging process. With multiple heads working simultaneously, the machine can fill multiple cans at once, significantly reducing the time it takes to package products. This increased efficiency not only saves time but also allows businesses to meet high production demands and maximize output.

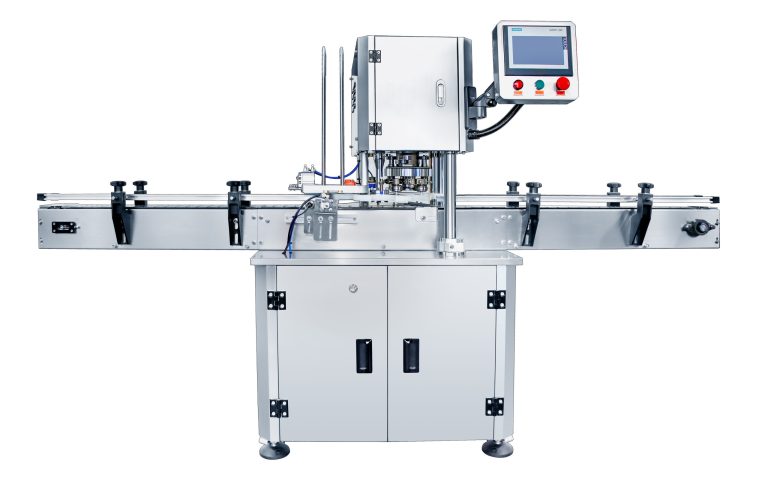

Furthermore, the Granules Multi Heads Weighing Filling Machine is designed for ease of use and maintenance. The user-friendly interface allows operators to easily set parameters and monitor the filling process, reducing the risk of errors and downtime. Additionally, the machine is built with high-quality materials and components, ensuring durability and reliability for long-term use.

Another advantage of using a Granules Multi Heads Weighing Filling Machine is its versatility in handling a wide range of granular products. Whether it’s coffee beans, nuts, seeds, or grains, the machine can accurately measure and fill different types of granules into tin cans with ease. This flexibility allows businesses to package a variety of products without the need for multiple machines.

Moreover, the Granules Multi Heads Weighing Filling Machine is designed to minimize product waste and maximize yield. By accurately measuring and filling each can, businesses can reduce product giveaway and optimize their packaging process. This not only saves costs but also improves overall efficiency and profitability.

In conclusion, the Granules Multi Heads Weighing Filling Machine offers numerous benefits for businesses looking to streamline their tin can packaging process. From precision and efficiency to versatility and yield optimization, this advanced technology is a game-changer for the food and beverage industry. By investing in a Granules Multi Heads Weighing Filling Machine, businesses can improve their packaging process, enhance product quality, and ultimately boost their bottom line.

How to Choose the Right Granules Multi Heads Weighing Filling Machine for Tin Can Production

When it comes to tin can production, choosing the right granules multi heads weighing filling machine is crucial for ensuring efficiency and accuracy in the filling process. Granules are a common type of product that is often packaged in tin cans, such as coffee, nuts, or pet food. The granules multi heads weighing filling machine is designed to accurately measure and fill a predetermined amount of granules into each tin can, ensuring consistency and precision in the packaging process.

One of the key factors to consider when choosing a granules multi heads weighing filling machine for tin can production is the number of heads. The number of heads on the machine will determine how many cans can be filled simultaneously, which can significantly impact the speed and efficiency of the filling process. Machines with more heads can fill more cans at once, increasing productivity and reducing the time it takes to fill a large batch of cans.

Another important factor to consider is the accuracy of the weighing system. The weighing system is responsible for measuring the precise amount of granules that are dispensed into each tin can. A highly accurate weighing system is essential for ensuring that each can is filled with the correct amount of product, preventing underfilling or overfilling that can lead to product waste or customer dissatisfaction. Look for a machine with a high-quality weighing system that is capable of accurately measuring small increments of weight to ensure consistent filling results.

In addition to the number of heads and the accuracy of the weighing system, it is also important to consider the speed and capacity of the machine. The speed of the machine will determine how quickly cans can be filled, while the capacity will determine how many cans can be filled in a given time frame. Choose a machine that can meet the production demands of your facility, ensuring that it can keep up with the volume of cans that need to be filled each day.

When selecting a granules multi heads weighing filling machine for tin can production, it is also important to consider the ease of use and maintenance of the machine. Look for a machine that is user-friendly and easy to operate, with intuitive controls and a clear interface that makes it easy for operators to set up and run the machine. Additionally, choose a machine that is easy to clean and maintain, with accessible components that can be easily serviced or replaced as needed.

In conclusion, choosing the right granules multi heads weighing filling machine for tin can production is essential for ensuring efficiency, accuracy, and consistency in the filling process. Consider factors such as the number of heads, the accuracy of the weighing system, the speed and capacity of the machine, and the ease of use and maintenance when selecting a machine for your facility. By carefully evaluating these factors and choosing a machine that meets your production needs, you can ensure that your tin can filling process runs smoothly and efficiently, resulting in high-quality products that meet customer expectations.