Table of Contents

Benefits of Using Olive Oil Filling Equipment

Olive oil is a staple in many kitchens around the world, prized for its health benefits and delicious flavor. As the demand for olive oil continues to grow, so does the need for efficient and reliable filling equipment. Olive oil filling equipment manufacturers play a crucial role in ensuring that olive oil producers can meet this demand while maintaining the quality and integrity of their product.

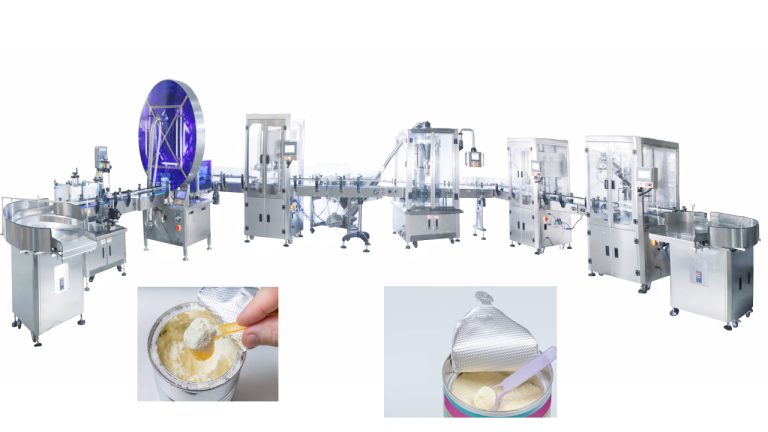

One of the main benefits of using olive oil filling equipment is increased efficiency. Manual filling processes can be time-consuming and labor-intensive, leading to bottlenecks in production and increased costs. By investing in automated filling equipment, olive oil producers can streamline their production process, increase output, and reduce labor costs. This allows producers to meet growing demand without sacrificing quality or consistency.

In addition to increased efficiency, olive oil filling equipment also offers improved accuracy and precision. Manual filling processes are prone to human error, leading to inconsistencies in fill levels and product quality. Automated filling equipment, on the other hand, can accurately measure and dispense precise amounts of olive oil, ensuring that each bottle is filled to the correct level. This not only improves the overall quality of the product but also helps to reduce waste and minimize product loss.

Another key benefit of using olive oil filling equipment is improved hygiene and sanitation. Manual filling processes can be messy and unhygienic, increasing the risk of contamination and spoilage. Automated filling equipment is designed to meet strict hygiene standards, with easy-to-clean surfaces and sanitary design features. This helps to ensure that the olive oil remains free from contaminants and maintains its freshness and flavor.

Furthermore, olive oil filling equipment can also help to extend the shelf life of the product. Proper filling techniques and equipment can help to minimize exposure to air and light, which can cause oxidation and spoilage. By using automated filling equipment, producers can ensure that each bottle is filled quickly and efficiently, reducing the risk of oxidation and extending the shelf life of the product. This not only helps to maintain the quality of the olive oil but also reduces waste and improves overall product consistency.

In conclusion, olive oil filling equipment manufacturers play a vital role in helping olive oil producers meet the growing demand for their products. By investing in automated filling equipment, producers can increase efficiency, accuracy, and precision, while also improving hygiene and extending the shelf life of their product. These benefits not only help producers to meet consumer demand but also ensure that the quality and integrity of the olive oil are maintained throughout the production process. As the demand for olive oil continues to grow, investing in high-quality filling equipment is essential for producers looking to stay competitive in the market.

Top Olive Oil Filling Equipment Manufacturers in the Industry

Olive oil is a staple in many kitchens around the world, known for its health benefits and delicious flavor. As the demand for high-quality olive oil continues to rise, so does the need for efficient and reliable filling equipment. Olive oil filling equipment manufacturers play a crucial role in ensuring that olive oil producers can package their product quickly and accurately.

One of the top olive oil filling equipment manufacturers in the industry is Filamatic. With over 65 years of experience in the packaging industry, Filamatic is known for its innovative and high-quality filling equipment. Their olive oil filling machines are designed to handle a wide range of bottle sizes and shapes, making them versatile and adaptable to different production needs. Filamatic’s machines are also equipped with advanced technology to ensure precise filling and minimize product waste.

Another leading manufacturer in the industry is E-PAK Machinery. E-PAK Machinery offers a wide range of filling equipment for olive oil producers, including gravity fillers, piston fillers, and overflow fillers. Their machines are designed to meet the specific needs of olive oil producers, with features such as stainless steel construction and easy-to-clean design. E-PAK Machinery is known for its commitment to quality and customer satisfaction, making them a trusted choice for olive oil producers around the world.

In addition to Filamatic and E-PAK Machinery, Liquid Packaging Solutions is another top manufacturer of olive oil filling equipment. Liquid Packaging Solutions offers a variety of filling machines, including volumetric fillers, net weigh fillers, and time-based fillers. Their machines are designed to handle a wide range of viscosities, making them suitable for filling both light and heavy olive oils. Liquid Packaging Solutions is known for its reliable and durable equipment, making them a popular choice among olive oil producers looking for long-lasting solutions.

When choosing an olive oil filling equipment manufacturer, it is important to consider factors such as production volume, bottle size, and budget. Each manufacturer offers a range of machines with different features and capabilities, so it is essential to choose one that meets your specific needs. It is also important to consider factors such as after-sales support and maintenance services, as these can impact the overall efficiency and performance of your filling equipment.

Overall, olive oil filling equipment manufacturers play a crucial role in the olive oil production process, ensuring that producers can package their product efficiently and accurately. With a wide range of manufacturers to choose from, olive oil producers can find the right filling equipment to meet their production needs. Whether you are a small artisanal producer or a large-scale manufacturer, there is a filling machine out there to help you package your olive oil with precision and ease.

How to Choose the Right Olive Oil Filling Equipment for Your Business

Olive oil is a staple in many kitchens around the world, known for its health benefits and delicious flavor. If you are in the business of producing olive oil, you know how important it is to have the right equipment to ensure that your product is packaged efficiently and accurately. One key piece of equipment that you will need is a reliable olive oil filling machine.

When it comes to choosing the right olive oil filling equipment for your business, there are a few key factors to consider. First and foremost, you will want to make sure that the equipment you choose is capable of handling the volume of olive oil that you need to fill. Whether you are a small artisanal producer or a large-scale operation, it is important to select a machine that can keep up with your production needs.

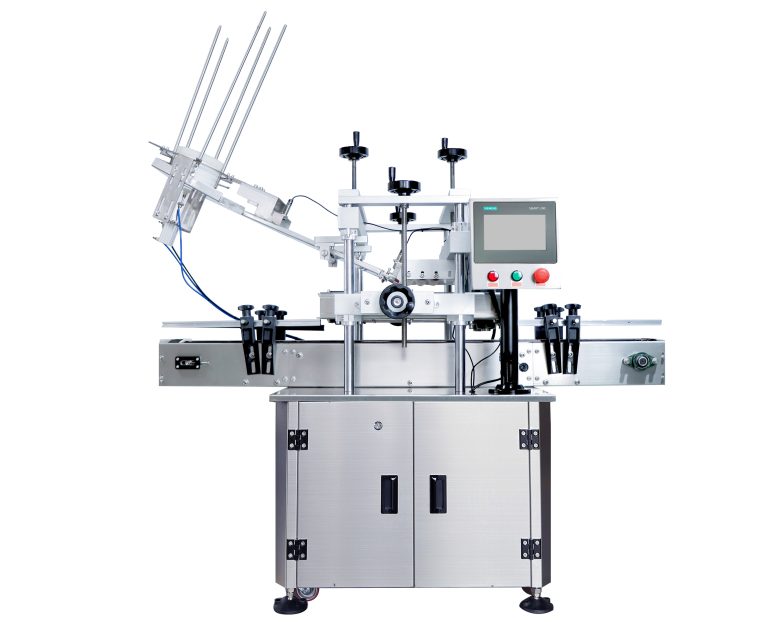

In addition to capacity, you will also want to consider the type of filling technology that is best suited to your needs. There are several different types of olive oil filling machines available, including piston fillers, gravity fillers, and overflow fillers. Each type of filler has its own advantages and disadvantages, so it is important to do your research and choose the one that is best suited to your specific requirements.

Another important factor to consider when choosing olive oil filling equipment is the level of automation that you require. Some filling machines are fully automated, while others require more manual intervention. The level of automation that is right for your business will depend on factors such as your production volume, budget, and the level of precision that you require.

When it comes to choosing a manufacturer for your olive oil filling equipment, it is important to do your due diligence. Look for a manufacturer with a solid reputation for quality and reliability, as well as a track record of providing excellent customer service. You may also want to consider factors such as the manufacturer’s location, warranty options, and after-sales support.

One reputable manufacturer of olive oil filling equipment is ABC Packaging Machines. ABC Packaging Machines has been in business for over 30 years and is known for producing high-quality filling machines that are designed to meet the needs of a wide range of industries, including the olive oil industry. Their machines are built to last, with durable construction and reliable performance.

In conclusion, choosing the right olive oil filling equipment for your business is a crucial decision that can have a significant impact on the efficiency and quality of your production process. By considering factors such as capacity, filling technology, automation level, and manufacturer reputation, you can ensure that you select the equipment that is best suited to your specific needs. With the right equipment in place, you can streamline your production process and ensure that your olive oil reaches your customers in perfect condition.