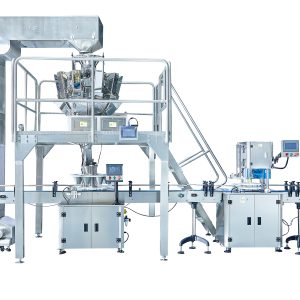

Automatic Milk Powde Can Packaging Line, include Round Accumulation Table, Automatic Round Bottle Labeling Machine, Empty Can UV Sterilization And Cleaning Machine, High Speed Automatic Can Seamer Machine, Single Head Powder Auger Filling Machine, Automatic Press Snap Capping Machine, Bottle Collecting Machine.

This line is applicable for packing of various kinds of powder such milk powder, coffee powder, protein powder, jaggery powder, spices etc, and it is an ideal equipment of food, pharmaceutical and other industries.

Round Accumulation Table is designed to handle circular packaging containers such as cans or bottles. They reduce cycle times because they feed and offload packaging lines at faster rates of up to 60 cans/minute or more, helping reduce labor costs and improve output efficiencies.

Automatic Round Bottle Labeling Machine is a type of equipment used in the packaging industry to apply labels onto round bottles or containers. These machines can be used for various applications, such as food and beverage, pharmaceuticals, cosmetics, and chemicals.

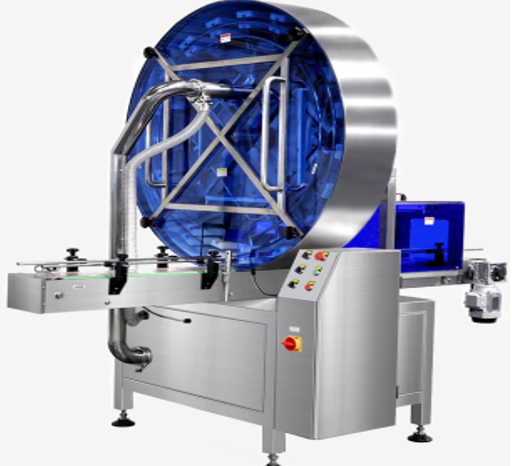

Empty Can UV Sterilization And Cleaning Machine can hold a large number of cans at one time and automatically arrange them on the conveyor belt of the packaging line, saving labor costs, improving the automation of the production line, and improving production efficiency.

High Speed Automatic Can Seamer Machine is suitable for sealing various round tin cans, such as tinplate cans, aluminum alloy cans, plastic cans, and paper cans.Reliable quality, easy operation . it is the necessary and ideal sealing equipment for food, beverage, pharmaceutical,chemical industry, etc.

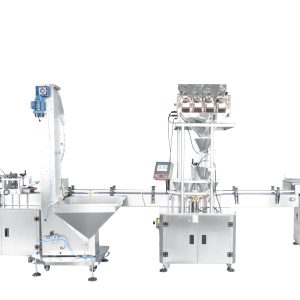

Single Head Powder Auger Filling Machine is applicable for filling of various kinds of powder such milk powder, coffee powder, protein powder, jaggery powder, spices etc, and it is an ideal equipment of food, pharmaceutical and other industries.

Automatic Press Snap Capping Machine is used for closing press type caps, it is made up by 3 parts: cap feeding system, cap loading system and cap closing system. It is characterized by its simple structure and high qualification rate. Can be used alone or inline. It suitable for various caps & bottles with good adaptability, widely used for pressing jar cap, plastic bottle cap, can caps, in industries like food, beverages, cosmetics, chemicals,etc.

Bottle Collecting Machine can accommodate many cans at a time, automatically collecting the cans of the packaging line, saving labor costs, improving production line automation, and thus improving production efficiency.Used at the end of the packaging line according to customer requirements.