Table of Contents

Benefits of Using a Peanut Butter Mixing Filling Machine

Peanut butter is a beloved spread enjoyed by people of all ages around the world. Whether it’s spread on toast, used in baking, or simply enjoyed by the spoonful, peanut butter is a versatile and delicious ingredient. However, making peanut butter can be a time-consuming and labor-intensive process, especially for commercial producers. That’s where a peanut butter mixing filling machine comes in.

One of the main benefits of using a peanut butter mixing filling machine is efficiency. These machines are designed to mix and fill peanut butter quickly and accurately, saving time and labor costs for producers. With a peanut butter mixing filling machine, producers can increase their production capacity and meet the demands of their customers more efficiently.

In addition to efficiency, a peanut butter mixing filling machine also ensures consistency in the quality of the product. By automating the mixing and filling process, producers can ensure that each batch of peanut butter is made to the same specifications, resulting in a consistent product that meets customer expectations every time. This consistency is crucial for building a strong brand reputation and customer loyalty.

Another benefit of using a peanut butter mixing filling machine is hygiene. These machines are designed to meet strict food safety standards, ensuring that the peanut butter is produced in a clean and sanitary environment. This is especially important for commercial producers who need to adhere to regulations and guidelines set by food safety authorities. By using a peanut butter mixing filling machine, producers can maintain high levels of hygiene and ensure the safety of their products.

Furthermore, a peanut butter mixing filling machine can help reduce waste and minimize product loss. These machines are designed to mix and fill peanut butter with precision, minimizing spillage and ensuring that every drop of product is used efficiently. This can result in cost savings for producers and a more sustainable production process overall.

Additionally, a peanut butter mixing filling machine can help improve the overall quality of the product. These machines are equipped with advanced technology that ensures thorough mixing and precise filling, resulting in a smooth and creamy peanut butter that is free from lumps or air bubbles. This high-quality product is sure to impress customers and keep them coming back for more.

In conclusion, the benefits of using a peanut butter mixing filling machine are numerous. From increased efficiency and consistency to improved hygiene and product quality, these machines offer a range of advantages for commercial producers. By investing in a peanut butter mixing filling machine, producers can streamline their production process, reduce waste, and deliver a high-quality product that meets customer expectations. Overall, a peanut butter mixing filling machine is a valuable tool for any producer looking to enhance their peanut butter production process.

How to Choose the Right Peanut Butter Mixing Filling Machine for Your Business

Peanut butter is a popular and versatile food product that is enjoyed by people of all ages. Whether it’s spread on toast, used as a dip for fruits and vegetables, or incorporated into baked goods, peanut butter is a staple in many households. If you are in the food industry and looking to expand your product line to include peanut butter, you will need the right equipment to efficiently mix and fill your product. One essential piece of equipment for this process is a peanut butter mixing filling machine.

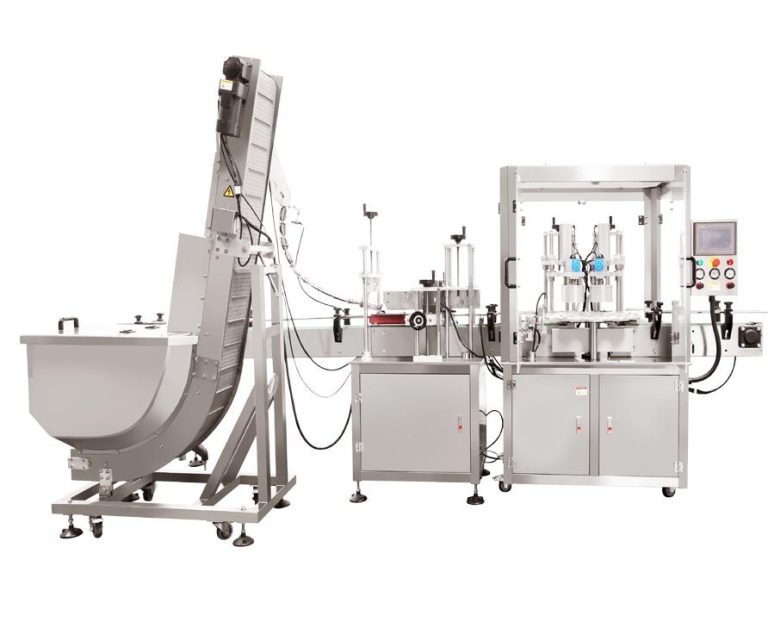

When choosing a peanut butter mixing filling machine for your business, there are several factors to consider to ensure that you select the right machine for your specific needs. One of the first things to consider is the capacity of the machine. Depending on the size of your production line and the demand for your product, you will need to choose a machine that can handle the volume of peanut butter you plan to produce. It is important to select a machine that can keep up with your production needs to avoid any bottlenecks in your manufacturing process.

Another important factor to consider when choosing a peanut butter mixing filling machine is the type of mixing technology used in the machine. There are several different types of mixing technologies available, including batch mixing, continuous mixing, and inline mixing. Each type of mixing technology has its own advantages and disadvantages, so it is important to choose a machine that uses the technology that best suits your production process.

In addition to mixing technology, you will also need to consider the filling technology used in the machine. There are several different types of filling technologies available, including piston filling, gravity filling, and pump filling. The type of filling technology you choose will depend on the viscosity of your peanut butter and the type of packaging you plan to use for your product. It is important to select a machine that can accurately fill your product into the desired packaging to ensure consistency and quality in your final product.

When choosing a peanut butter mixing filling machine, it is also important to consider the level of automation and control offered by the machine. Some machines offer manual control, while others offer fully automated control with programmable settings. The level of automation and control you choose will depend on your production process and the level of precision and consistency you require in your product. It is important to select a machine that offers the right level of automation and control to meet your production needs.

Finally, when choosing a peanut butter mixing filling machine, it is important to consider the overall quality and reliability of the machine. Look for a machine that is made from high-quality materials and is built to last. It is also important to choose a machine from a reputable manufacturer with a track record of producing reliable and durable equipment. Investing in a high-quality machine will ensure that your production process runs smoothly and efficiently, leading to a consistent and high-quality product.

In conclusion, choosing the right peanut butter mixing filling machine for your business is essential to ensure the success of your peanut butter production process. Consider factors such as capacity, mixing and filling technology, automation and control, and overall quality and reliability when selecting a machine. By carefully evaluating these factors and choosing a machine that meets your specific needs, you can ensure that your peanut butter production process is efficient, consistent, and produces a high-quality product that will satisfy your customers.