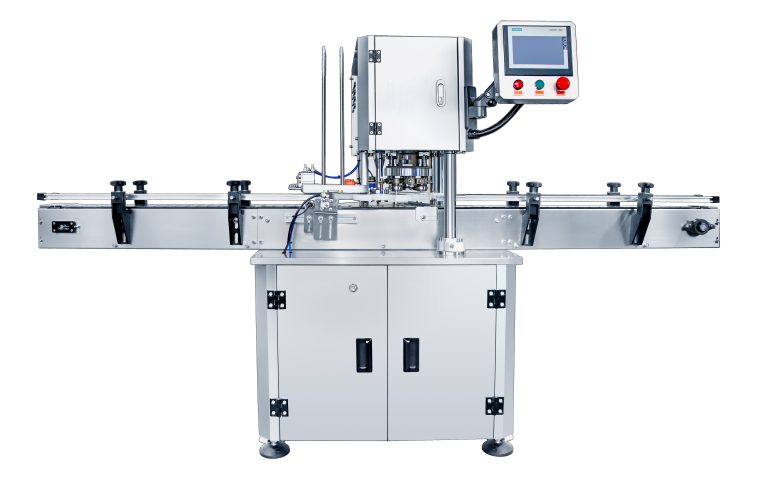

Single-head servo capping machines have emerged as a game-changer for packaging lines for several compelling reasons.

Firstly, they offer precise and consistent capping. The servo technology enables accurate control of torque and pressure, ensuring that each cap is tightened to the exact specification. This leads to secure and leak-proof closures, enhancing the quality and integrity of the packaged products.

The single-head design provides focused attention to each container, allowing for meticulous capping operations. This is especially crucial for products that require precise capping to maintain their freshness, safety, or performance.

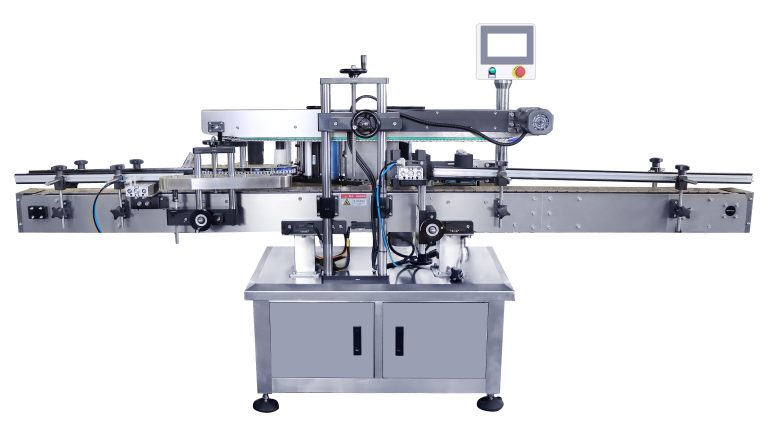

These machines are highly adaptable. They can handle a wide variety of cap types and container shapes and sizes, providing flexibility for packaging lines that deal with diverse products.

The speed and efficiency of single-head servo capping machines are remarkable. They can complete the capping process quickly, reducing the overall packaging time and increasing the throughput of the production line.

The advanced control systems of these machines offer real-time monitoring and diagnostics. This enables operators to identify and address any issues promptly, minimizing downtime and maximizing productivity.

Furthermore, they often come with user-friendly interfaces and programmable settings, making it easy for operators to adjust parameters according to specific packaging requirements.

In conclusion, single-head servo capping machines have transformed packaging lines by delivering precise capping, adaptability, speed, advanced control, and user-friendly operation, making them an essential component for efficient and high-quality packaging processes.