Inhoudsopgave

Benefits of Using Automated Rice Can Packaging Production Line

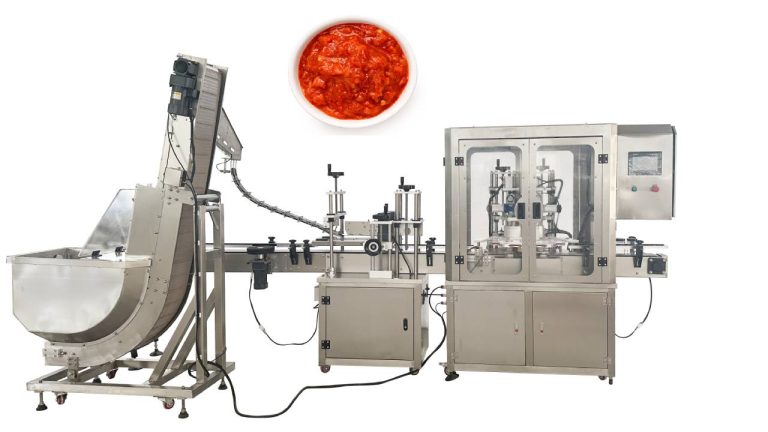

Rice can packaging production lines have revolutionized the way rice is packaged and distributed. These automated systems offer a wide range of benefits that make them a popular choice for rice manufacturers looking to streamline their operations and improve efficiency.

One of the key benefits of using an automated rice can packaging production line is the increased speed and efficiency it offers. These systems are designed to handle large volumes of rice quickly and accurately, reducing the time and labor required to package the product. This not only helps to increase productivity but also ensures that orders are fulfilled in a timely manner, leading to higher customer satisfaction.

In addition to speed and efficiency, automated rice can packaging production lines also offer improved accuracy and consistency. These systems are programmed to package rice in precise quantities, ensuring that each can contains the correct amount of product. This helps to reduce waste and minimize errors, leading to higher quality products and lower production costs.

Another benefit of using an automated rice can packaging production line is the ability to customize packaging options. These systems can be easily adjusted to accommodate different can sizes, packaging materials, and labeling requirements, allowing manufacturers to meet the specific needs of their customers. This flexibility not only helps to improve customer satisfaction but also allows manufacturers to adapt to changing market demands quickly and efficiently.

Automated rice can packaging production lines also offer improved safety and hygiene benefits. These systems are designed to minimize human contact with the product, reducing the risk of contamination and ensuring that the rice remains fresh and safe for consumption. Additionally, automated systems are equipped with advanced safety features to protect workers from potential hazards, further enhancing the overall safety of the production process.

Furthermore, automated rice can packaging production lines are cost-effective solutions for manufacturers looking to reduce overhead costs and increase profitability. These systems require minimal maintenance and supervision, leading to lower operating costs and higher overall efficiency. Additionally, the increased speed and accuracy of automated systems help to reduce waste and improve product quality, leading to higher customer satisfaction and repeat business.

Overall, the benefits of using an automated rice can packaging production line are numerous and significant. From increased speed and efficiency to improved accuracy and consistency, these systems offer a wide range of advantages that can help manufacturers streamline their operations and improve their bottom line. With the ability to customize packaging options, enhance safety and hygiene, and reduce costs, automated rice can packaging production lines are a valuable investment for any rice manufacturer looking to stay competitive in today’s market.

How to Optimize Efficiency in Rice Can Packaging Production Line Operations

Rice can packaging production lines are essential in the food industry for efficiently packaging rice into cans for distribution and sale. To ensure that these operations run smoothly and efficiently, it is important to optimize the production line for maximum output and minimal downtime. By implementing certain strategies and best practices, companies can improve the efficiency of their rice can packaging production line operations.

One key aspect of optimizing efficiency in rice can packaging production line operations is to streamline the workflow. This can be achieved by organizing the production line in a logical and efficient manner, with each step in the packaging process flowing seamlessly into the next. By minimizing the distance between each workstation and eliminating unnecessary steps, companies can reduce the time it takes to package rice into cans.

Another important factor in optimizing efficiency is to invest in high-quality equipment and machinery. By using modern and reliable packaging machines, companies can increase the speed and accuracy of their packaging operations. This not only improves efficiency but also reduces the risk of downtime due to equipment malfunctions or breakdowns. Regular maintenance and servicing of machinery are also crucial to ensure that the production line runs smoothly and efficiently.

In addition to equipment, it is essential to train and educate staff on the proper use of machinery and equipment. By providing comprehensive training programs and ongoing support, companies can ensure that their employees are skilled and knowledgeable in operating the packaging line. This can help to minimize errors and reduce the risk of accidents, leading to a more efficient and productive production line.

Furthermore, companies can optimize efficiency by implementing automation and technology into their packaging operations. By using automated systems for tasks such as filling, sealing, and labeling cans, companies can increase the speed and accuracy of their packaging processes. This not only improves efficiency but also reduces the need for manual labor, freeing up employees to focus on other tasks.

To further optimize efficiency, companies can also implement quality control measures to ensure that each can of rice is packaged correctly and meets the required standards. By conducting regular inspections and quality checks throughout the packaging process, companies can identify and address any issues or defects before they escalate. This can help to reduce waste and rework, leading to a more efficient and cost-effective production line.

Overall, optimizing efficiency in rice can packaging production line operations requires a combination of strategic planning, investment in equipment and technology, training of staff, and implementation of quality control measures. By following these best practices and continuously seeking ways to improve and innovate, companies can achieve maximum output and profitability in their packaging operations. By prioritizing efficiency and productivity, companies can stay competitive in the food industry and meet the demands of consumers for high-quality packaged rice products.