Inhoudsopgave

Benefits of Using Oatmeal Can Weighing Filling and Sealing Machine Line Manufacturer

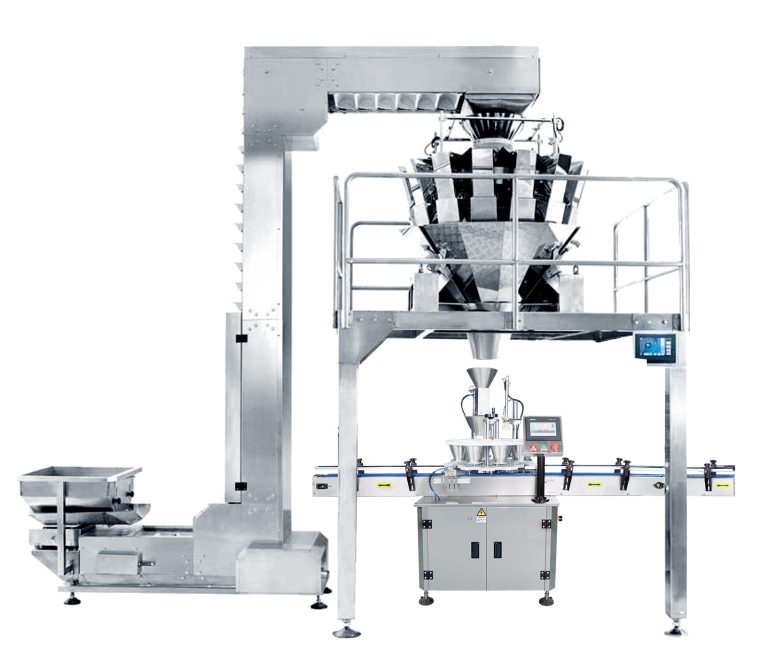

In the food packaging industry, efficiency and accuracy are key factors in ensuring the success of a product. One of the most important aspects of packaging is the filling and sealing process, which can be a time-consuming and labor-intensive task if done manually. This is where oatmeal can weighing filling and sealing machine line manufacturers come into play, offering a solution that streamlines the packaging process and improves overall productivity.

One of the main benefits of using an oatmeal can weighing filling and sealing machine line manufacturer is the precision and consistency it provides. These machines are equipped with advanced technology that allows them to accurately measure and dispense the exact amount of oatmeal into each can, ensuring that every package is filled to the correct weight. This level of accuracy is crucial in maintaining product quality and meeting regulatory standards.

Furthermore, oatmeal can weighing filling and sealing machine line manufacturers offer a high level of automation, reducing the need for manual labor and increasing production efficiency. With the ability to fill and seal multiple cans simultaneously, these machines can significantly increase output and reduce production time. This not only saves time and labor costs but also allows manufacturers to meet the demands of a fast-paced market.

Another benefit of using an oatmeal can weighing filling and sealing machine line manufacturer is the versatility it offers. These machines can be customized to accommodate different can sizes and packaging requirements, making them suitable for a wide range of products. Whether you are packaging individual servings or bulk quantities of oatmeal, these machines can be tailored to meet your specific needs.

In addition to efficiency and versatility, oatmeal can weighing filling and sealing machine line manufacturers also offer improved product safety and hygiene. These machines are designed to meet strict food safety standards, with features such as stainless steel construction and easy-to-clean surfaces. This helps to prevent contamination and ensure that your oatmeal is packaged in a safe and sanitary manner.

Overall, the benefits of using an oatmeal can weighing filling and sealing machine line manufacturer are clear. From increased efficiency and productivity to improved accuracy and product safety, these machines offer a comprehensive solution for packaging oatmeal. By investing in a quality machine from a reputable manufacturer, you can streamline your packaging process, reduce costs, and enhance the overall quality of your product.

In conclusion, oatmeal can weighing filling and sealing machine line manufacturers play a crucial role in the food packaging industry, offering a range of benefits that can help manufacturers improve their operations and meet the demands of a competitive market. With their precision, automation, versatility, and safety features, these machines provide a cost-effective and efficient solution for packaging oatmeal. By choosing a reputable manufacturer and investing in a quality machine, you can take your packaging process to the next level and ensure the success of your product in the marketplace.

How to Choose the Right Oatmeal Can Weighing Filling and Sealing Machine Line Manufacturer

When it comes to choosing the right oatmeal can weighing filling and sealing machine line manufacturer, there are several factors to consider. These machines are essential for packaging oatmeal in cans efficiently and accurately. With so many manufacturers in the market, it can be overwhelming to make the right choice. In this article, we will discuss some key points to keep in mind when selecting a manufacturer for your oatmeal can weighing filling and sealing machine line.

First and foremost, it is important to consider the reputation of the manufacturer. Look for a company that has a proven track record of producing high-quality machines that are reliable and durable. You can research online reviews and testimonials from other customers to get an idea of the manufacturer’s reputation. Additionally, you can ask for references from the manufacturer and speak to other businesses that have used their machines to gauge their satisfaction.

Another important factor to consider is the technology and features offered by the manufacturer. Look for a manufacturer that uses the latest technology in their machines to ensure efficiency and accuracy in the packaging process. Features such as automatic weighing, filling, and sealing capabilities can help streamline your production process and increase productivity. Additionally, look for machines that offer customization options to meet your specific packaging needs.

Cost is also a crucial factor to consider when choosing a manufacturer for your oatmeal can weighing filling and sealing machine line. While it is important to stay within your budget, it is equally important not to compromise on quality. Look for a manufacturer that offers competitive pricing without sacrificing the quality of their machines. Consider the long-term costs of maintenance and repairs when making your decision to ensure that you are getting the best value for your money.

Customer service and support are essential when selecting a manufacturer for your oatmeal can weighing filling and sealing machine line. Look for a company that offers excellent customer service and support to assist you with any issues or questions that may arise. A manufacturer that provides training for your staff on how to operate and maintain the machines can also be beneficial in ensuring smooth operation and minimizing downtime.

In conclusion, choosing the right oatmeal can weighing filling and sealing machine line manufacturer is a crucial decision that can impact the efficiency and productivity of your packaging process. Consider factors such as reputation, technology, cost, and customer service when making your decision. By taking the time to research and evaluate different manufacturers, you can find a reliable partner that will help you meet your packaging needs effectively.