Inhoudsopgave

Introduction

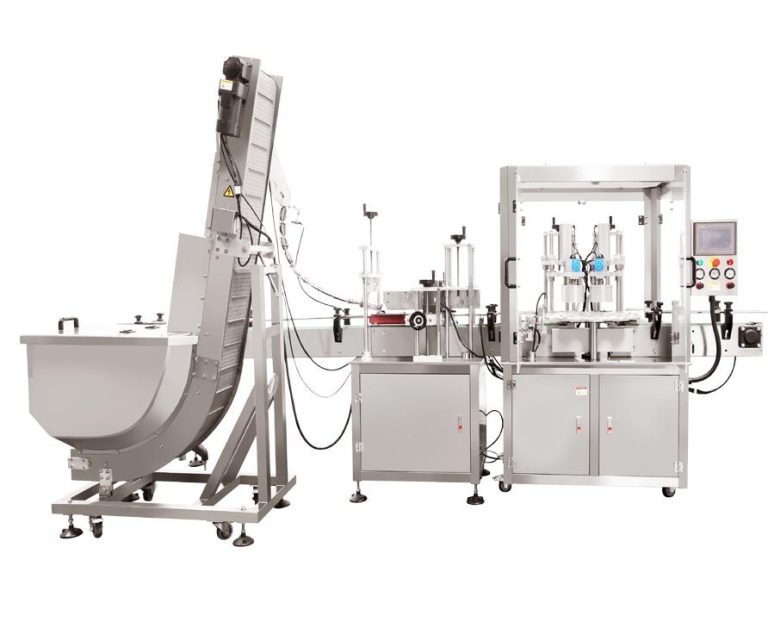

Chili sauce is a zesty and flavorful condiment loved by many. To preserve its taste, aroma, and nutritional value, freshness is of utmost importance. The twist off chili sauce glass jar vacuum capper machine plays a pivotal role in achieving this goal. In this blog, we’ll explore the various ways this machine ensures that chili sauce stays fresh from production to the consumer’s table.

Creating a Vacuum Environment

The core function of the twist off glass jar vacuum capper machine is to create a vacuum inside the glass jar before sealing it. Oxygen is the enemy of freshness when it comes to chili sauce. When chili sauce is exposed to oxygen, it can trigger a series of chemical reactions. Oxidation can cause the chili sauce to lose its vibrant color, as well as its characteristic flavor compounds.

The vacuum capper machine uses a powerful suction mechanism to remove the air from the jar. Once most of the oxygen is eliminated, the growth of aerobic microorganisms such as bacteria, molds, and yeasts is severely inhibited. These microorganisms are often responsible for spoiling the chili sauce, causing it to develop off – flavors, strange odors, and even visible signs of decay. By creating a low – oxygen environment, the machine significantly extends the shelf life of the chili sauce.

Tight and Secure Sealing

The twist off feature of the capper machine ensures a tight and secure seal on the glass jar. A proper seal is essential for maintaining the vacuum inside the jar and preventing any external air or contaminants from entering.

The machine is designed to apply the right amount of pressure when attaching the twist off cap to the jar. This pressure creates a hermetic seal that is difficult to break. The cap is engineered to fit snugly on the jar’s opening, with no gaps or leaks. Even during transportation and storage, the seal remains intact, protecting the chili sauce from the elements.

Hygienic Filling and Capping Process

The twist off chili sauce glass jar vacuum capper machine is built with hygiene in mind. Before the filling process begins, the jars are often pre – cleaned and sanitized. The machine itself is made from high – quality, food – grade materials that are easy to clean and disinfect.

During the filling process, the chili sauce is transferred into the jars in a controlled environment. The vacuum capper then quickly seals the jars, minimizing the exposure of the sauce to the outside air. This reduces the risk of contamination from dust, dirt, and other airborne particles that could potentially spoil the sauce.

Temperature and Humidity Control

Some advanced twist off glass jar vacuum capper machines are equipped with temperature and humidity control features. Maintaining the right temperature and humidity levels is crucial for preserving the freshness of chili sauce.

If the temperature is too high, the chili sauce may start to break down more quickly, losing its flavor and texture. High humidity can also lead to the growth of mold and bacteria. The capper machine can regulate these environmental factors during the filling and sealing process, ensuring that the chili sauce is stored in optimal conditions from the moment it is packaged.

Quality Assurance and Monitoring

Manufacturers often use the twist off chili sauce glass jar vacuum capper machine in conjunction with quality control systems. These systems can monitor the vacuum levels inside the jars, the tightness of the seals, and other important parameters.

Any jars that do not meet the required standards can be quickly identified and removed from the production line. This ensures that only jars with a proper vacuum seal and high – quality filling reach the market. By maintaining strict quality control, the machine helps to guarantee the freshness and safety of the chili sauce.

Conclusion

The twist off chili sauce glass jar vacuum capper machine is an essential tool for chili sauce manufacturers who want to ensure the freshness of their products. Through creating a vacuum environment, providing a tight seal, maintaining a hygienic process, controlling temperature and humidity, and implementing quality assurance measures, this machine helps to preserve the flavor, color, and nutritional value of chili sauce for an extended period. Consumers can then enjoy the delicious and fresh taste of chili sauce, confident in its quality and safety.