Inhoudsopgave

Benefits of Using Filling and Seaming Machines in Food Packaging

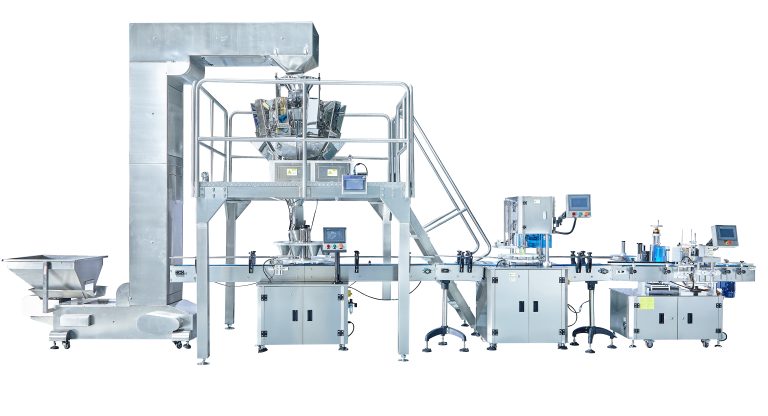

Filling and seaming machines are essential equipment in the food packaging industry, providing efficient and precise filling and sealing of various food products. These machines offer numerous benefits that help improve productivity, reduce waste, and ensure the quality and safety of packaged food products.

One of the key benefits of using filling and seaming machines is their ability to automate the packaging process. These machines are designed to fill containers with a specific amount of product and seal them quickly and accurately, eliminating the need for manual labor and reducing the risk of human error. This automation not only increases efficiency but also ensures consistency in the packaging process, resulting in uniform and professional-looking products.

In addition to automation, filling and seaming machines also offer increased speed and throughput compared to manual packaging methods. These machines can fill and seal hundreds or even thousands of containers per hour, allowing food manufacturers to meet high production demands and deliver products to market quickly. This increased speed not only improves productivity but also helps reduce lead times and improve overall operational efficiency.

Another benefit of using filling and seaming machines is their versatility and flexibility. These machines can be easily adjusted to accommodate different container sizes, shapes, and types of food products, making them suitable for a wide range of packaging applications. Whether packaging liquid products like juices and sauces or solid products like grains and snacks, filling and seaming machines can be customized to meet the specific needs of food manufacturers.

Furthermore, filling and seaming machines help reduce waste and improve sustainability in the food packaging process. By accurately filling containers with the right amount of product, these machines help minimize product overfill and underfill, reducing product waste and maximizing yield. Additionally, the precise sealing capabilities of these machines help extend the shelf life of packaged food products, reducing the risk of spoilage and food waste.

Moreover, filling and seaming machines play a crucial role in ensuring the quality and safety of packaged food products. These machines are designed to maintain strict hygiene standards, with features such as stainless steel construction, easy-to-clean surfaces, and sanitary design principles. This helps prevent contamination and ensures that food products are packaged in a clean and safe environment, meeting regulatory requirements and consumer expectations for food safety.

In conclusion, filling and seaming machines offer numerous benefits for food manufacturers looking to improve their packaging processes. From automation and increased speed to versatility and sustainability, these machines help enhance productivity, reduce waste, and ensure the quality and safety of packaged food products. By investing in filling and seaming machines, food manufacturers can streamline their packaging operations, meet high production demands, and deliver high-quality products to consumers.

Tips for Choosing the Right Filling and Seaming Machine for Your Production Line

Filling and seaming machines are essential equipment for companies in the food and beverage industry. These machines are used to fill containers with liquid or semi-liquid products and seal them with a lid or cap. Choosing the right filling and seaming machine for your production line is crucial to ensure efficiency and quality in your packaging process.

When selecting a filling and seaming machine, there are several factors to consider. One of the most important factors is the type of product you will be filling and sealing. Different products have different viscosities and flow properties, which will affect the type of filling and seaming machine you need. For example, a thin liquid product like water will require a different machine than a thick, chunky product like salsa.

Another important factor to consider is the speed and capacity of the machine. You will need to determine how many containers you need to fill and seal per minute to meet your production goals. Some machines are designed for high-speed production lines, while others are better suited for smaller batch sizes. It is important to choose a machine that can keep up with your production demands without sacrificing quality.

The size and shape of the containers you will be filling and sealing is also an important consideration. Some machines are designed to fill and seal specific types of containers, such as cans, bottles, or pouches. Make sure the machine you choose is compatible with the containers you will be using in your production line.

In addition to the type of product, speed, and container size, you should also consider the level of automation you need in a filling and seaming machine. Fully automated machines can increase efficiency and reduce the risk of human error, but they may also be more expensive. Semi-automated machines offer a balance between automation and manual control, allowing for more flexibility in production.

Maintenance and support are also important factors to consider when choosing a filling and seaming machine. Look for a machine that is easy to clean and maintain, with readily available spare parts and technical support. Regular maintenance is essential to keep your machine running smoothly and prevent costly downtime.

When researching filling and seaming machines, be sure to read reviews and testimonials from other companies in your industry. This can give you valuable insights into the performance and reliability of different machines. You may also want to consult with a packaging equipment specialist to help you evaluate your options and make an informed decision.

In conclusion, choosing the right filling and seaming machine for your production line is a critical decision that can impact the efficiency and quality of your packaging process. Consider factors such as the type of product, speed and capacity, container size, level of automation, maintenance, and support when selecting a machine. By taking the time to research and evaluate your options, you can find a filling and seaming machine that meets your specific needs and helps you achieve your production goals.