Inhoudsopgave

Benefits of Using Automatic Dual Head Screw Capping Machine for Sugar Bottle

In the world of manufacturing, efficiency and precision are key factors in ensuring the success of a product. When it comes to packaging sugar bottles, having a reliable capping machine can make a significant difference in the overall production process. One such machine that has been gaining popularity in the industry is the automatic dual head screw capping machine.

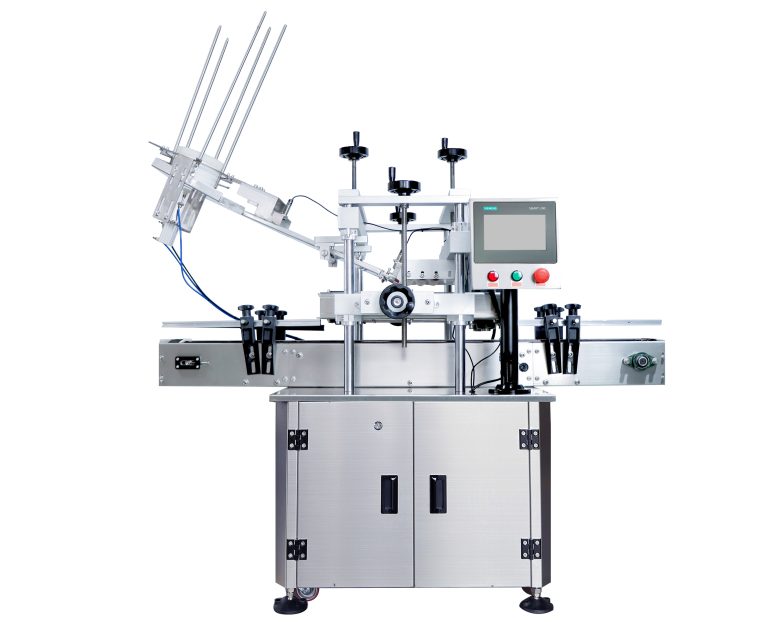

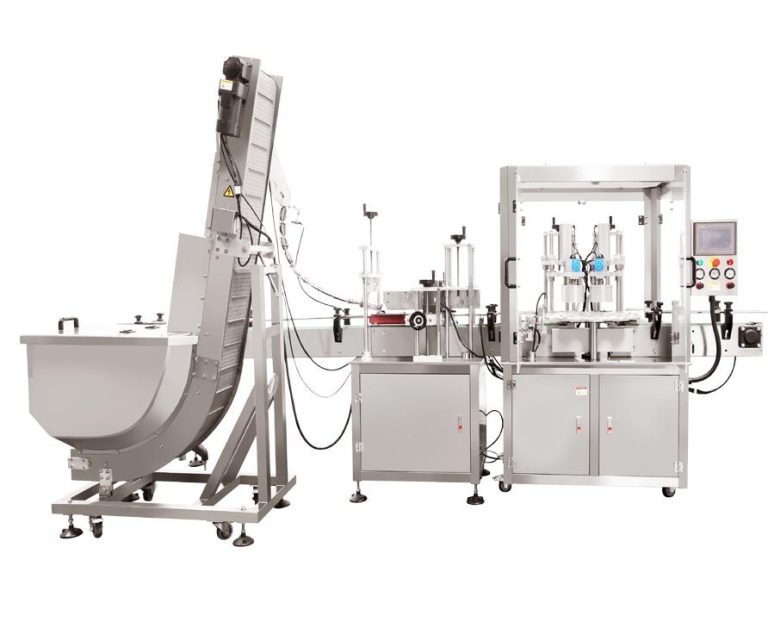

This innovative machine is designed to streamline the capping process by automatically tightening the caps on sugar bottles with precision and speed. The dual head feature allows for two bottles to be capped simultaneously, increasing the efficiency of the production line. This means that more bottles can be capped in a shorter amount of time, ultimately leading to increased productivity and cost savings for manufacturers.

One of the key benefits of using an automatic dual head screw capping machine for sugar bottles is the consistency and accuracy it provides. Manual capping can often result in unevenly tightened caps, which can lead to leakage or spoilage of the product. With an automatic capping machine, each bottle is capped with the same amount of pressure, ensuring a tight seal every time. This not only improves the quality of the product but also reduces the risk of product recalls due to faulty packaging.

Another advantage of using an automatic dual head screw capping machine is the reduction in labor costs. Manual capping can be a time-consuming and labor-intensive process, requiring multiple workers to cap each bottle individually. By automating this process, manufacturers can significantly reduce the number of workers needed on the production line, saving both time and money. Additionally, the machine can run continuously without the need for breaks, further increasing efficiency and productivity.

In addition to the cost savings and efficiency improvements, an automatic dual head screw capping machine also offers versatility in capping different sizes and shapes of sugar bottles. The machine can be easily adjusted to accommodate various bottle sizes, making it a versatile solution for manufacturers with diverse product lines. This flexibility allows for seamless integration into existing production lines without the need for extensive retooling or modifications.

Furthermore, the automatic dual head screw capping machine is designed with user-friendly features that make it easy to operate and maintain. The machine is equipped with intuitive controls and settings that can be easily adjusted to meet specific production requirements. Additionally, the machine is built with durable materials that are designed to withstand the rigors of continuous use, ensuring long-term reliability and performance.

Overall, the benefits of using an automatic dual head screw capping machine for sugar bottles are clear. From increased efficiency and productivity to improved product quality and cost savings, this innovative machine offers a range of advantages for manufacturers looking to streamline their production processes. By investing in this technology, manufacturers can stay ahead of the competition and meet the demands of today’s fast-paced market.

How to Choose the Right Automatic Dual Head Screw Capping Machine for Sugar Bottle

When it comes to packaging sugar bottles, having the right capping machine is essential to ensure efficiency and accuracy in the production process. One popular option for capping sugar bottles is the automatic dual head screw capping machine. This machine is designed to cap bottles with screw caps quickly and accurately, making it an ideal choice for high-volume production lines. However, with so many options available on the market, choosing the right automatic dual head screw capping machine for sugar bottles can be a daunting task. In this article, we will discuss some key factors to consider when selecting the right machine for your production needs.

First and foremost, it is important to consider the speed and capacity of the automatic dual head screw capping machine. The speed of the machine will determine how many bottles can be capped per minute, while the capacity will determine the maximum bottle size that can be accommodated. It is important to choose a machine that can meet the production demands of your facility without compromising on quality.

Another important factor to consider is the level of automation offered by the machine. Some automatic dual head screw capping machines come with advanced features such as automatic cap feeding and bottle positioning, which can help streamline the production process and reduce the risk of human error. It is important to choose a machine that offers the right level of automation for your specific production needs.

In addition to speed, capacity, and automation, it is also important to consider the overall build quality and durability of the automatic dual head screw capping machine. A machine that is built to last will require less maintenance and downtime, ultimately saving you time and money in the long run. Look for machines that are made from high-quality materials and come with a warranty to ensure peace of mind.

When choosing an automatic dual head screw capping machine for sugar bottles, it is also important to consider the compatibility of the machine with your existing production line. Make sure that the machine can be easily integrated into your current setup without requiring extensive modifications. This will help minimize downtime and ensure a smooth transition to the new machine.

Finally, it is important to consider the reputation of the manufacturer when choosing an automatic dual head screw capping machine. Look for manufacturers with a proven track record of producing high-quality machines and providing excellent customer support. Reading reviews and testimonials from other customers can also help you gauge the reliability and performance of the machine.

In conclusion, choosing the right automatic dual head screw capping machine for sugar bottles is a crucial decision that can impact the efficiency and productivity of your production line. By considering factors such as speed, capacity, automation, build quality, compatibility, and manufacturer reputation, you can make an informed decision that will benefit your business in the long run. Take the time to research and compare different machines to find the one that best meets your specific production needs.

Maintenance Tips for Automatic Dual Head Screw Capping Machine for Sugar Bottle

Maintaining an automatic dual head screw capping machine for sugar bottles is essential to ensure its optimal performance and longevity. Regular maintenance not only prevents breakdowns and costly repairs but also ensures that the machine operates efficiently, resulting in consistent and high-quality capping of sugar bottles. In this article, we will discuss some key maintenance tips to keep your automatic dual head screw capping machine in top condition.

One of the most important maintenance tasks for an automatic dual head screw capping machine is regular cleaning. Over time, dust, debris, and sugar residue can build up on the machine, affecting its performance. It is recommended to clean the machine after each use to prevent any buildup. Use a soft cloth and a mild detergent to wipe down the machine, paying special attention to the capping heads and the conveyor belts. Make sure to dry the machine thoroughly before using it again to prevent any water damage.

In addition to regular cleaning, it is important to lubricate the moving parts of the machine to ensure smooth operation. Lubrication helps reduce friction and wear on the components, extending the life of the machine. Use a high-quality lubricant recommended by the manufacturer and apply it to the capping heads, conveyor belts, and any other moving parts. Be sure to follow the manufacturer’s instructions on how often to lubricate the machine to avoid over-lubrication, which can attract dust and debris.

Another important maintenance tip for an automatic dual head screw capping machine is to regularly inspect the machine for any signs of wear or damage. Check the capping heads, conveyor belts, and other components for any cracks, dents, or loose parts. Replace any worn or damaged parts immediately to prevent further damage to the machine. It is also a good idea to keep spare parts on hand to quickly replace any components that may fail during operation.

Regular calibration of the machine is also essential to ensure accurate capping of sugar bottles. Over time, the machine may become misaligned, affecting the tightness of the caps on the bottles. Follow the manufacturer’s instructions on how to calibrate the machine and perform this task regularly to maintain consistent capping results. If you notice any issues with the capping quality, recalibrate the machine immediately to prevent any defects in the finished products.

Lastly, it is important to train your staff on how to properly operate and maintain the automatic dual head screw capping machine. Make sure that all operators are familiar with the machine’s functions and safety procedures to prevent any accidents or damage to the machine. Provide regular training sessions on maintenance tasks and troubleshooting techniques to ensure that your staff can effectively maintain the machine and address any issues that may arise during operation.

In conclusion, regular maintenance of an automatic dual head screw capping machine for sugar bottles is crucial to ensure its optimal performance and longevity. By following these maintenance tips, you can keep your machine in top condition and continue to produce high-quality capped sugar bottles efficiently. Remember to clean, lubricate, inspect, calibrate, and train your staff regularly to keep your machine running smoothly for years to come.