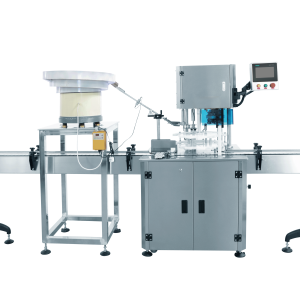

High Speed Automatic Washable Negative Pressure Vacuum Can Sealer, Automatic Vacuum Can Sealing Machine

The machine is mainly suitable for all kinds of canned fruit, canned meat, canned pet food, canned seafood, etc. With advanced design, reasonable structure and simple operation, it is an ideal and necessary packaging equipment for the food, medicine, milk powder and chemical industry.

Main Features:

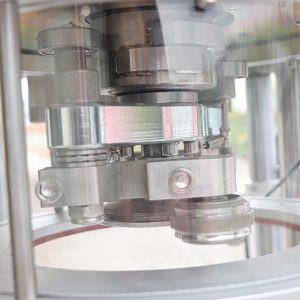

1. With the help of the suction effect of the vacuum pump, the air storage tank connected to the sealing chamber of the can sealing machine is permanently in a negative pressure state. When the can sealing machine starts to run, the air storage tank generates suction due to negative pressure, and sucks the air in the sealing chamber into the air storage tank, forming a negative pressure in the sealing chamber, and a negative pressure state in the tank, sealing the can.

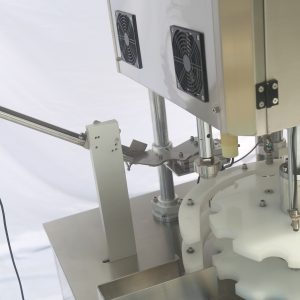

2. The main motor of the equipment and the turntable motor are servo controlled to make the equipment run more safely, stably and intelligently. The turntable is started only when there is a can; the speed of the turntable can be adjusted separately; when a stuck can occurs, the turntable will automatically stop, and the fault can be removed after one-key reset. Equipment damage and safety accidents caused by incorrect operation of the equipment.

3.The vacuum pump does not need to be connected to another water pipe, and the machine can be used when it is connected to electricity and gas;

4. The height difference of the can body is 10-20mm, the lid is the same, no need to change the mold, the machine automatically adjusts the sealing.

5. The can body does not rotate during the sealing process, which is safer, especially suitable for the use of sauces, minced meat and liquid products.

6. It is suitable for product sealing of tinplate cans, aluminum cans, plastic cans and iron cans. It is an ideal packaging equipment for pet food, seafood products, canned fish and other industries.

Main parameters:

1. Number of sealed cans: 1

2. Vacuum degree: -0.03~-0.04Mpa

3. Sealing speed: 30-45 cans/min (depending on can type, can size, products and vacuum degree)

4. Sealing height: 35-200mm

5. Sealing diameter: 35-105mm

6. Working temperature: -50℃~60℃, working humidity: 35~85%

7. Working power supply: three-phase 380V 50Hz

8. Total power: 5.5Kw (including vacuum pump 3Kw)

9. Weight: 480kg (including gas tank 80kg)

10. Air consumption: 35L/min

11. Conveyor belt height: 850mm

12. Appearance size: L2050* W 1200* H 1400mm (about)