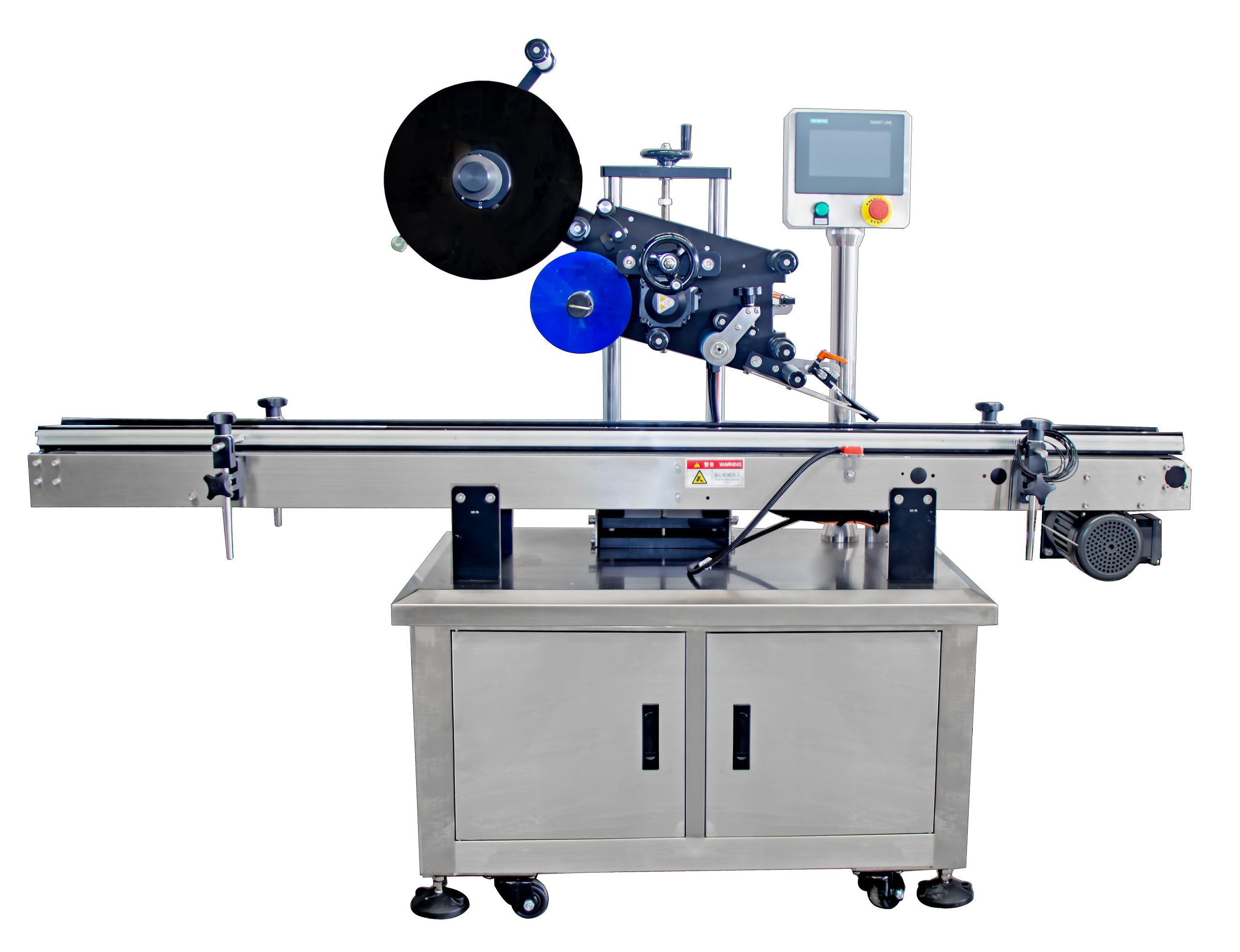

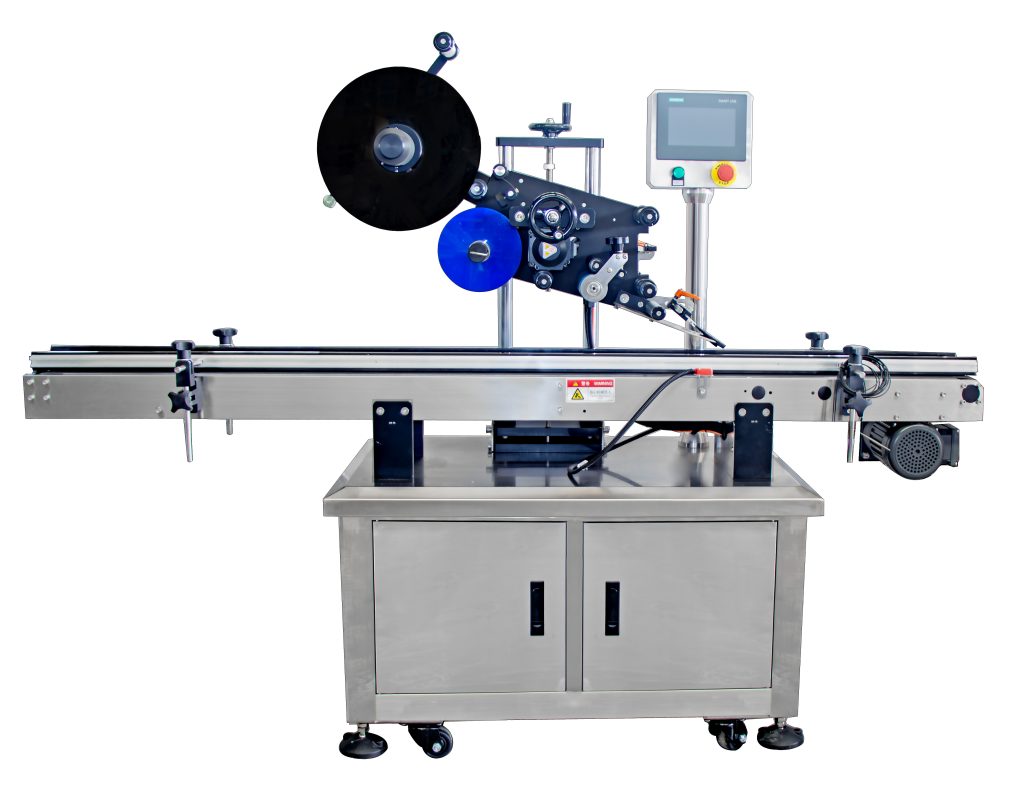

Automatic Flat Top Labeling Machine, Cap Top Side Labeler Equipment

The machine is designed to apply labels to the flat top surface of a product automatically. These machines are commonly used in industries such as food and beverage, cosmetics, and pharmaceuticals, where product labeling requirements may include product identification, branding, or regulatory information.

Main Features:

1. Wide application range, can meet product width labeling and self-adhesive film with product width 30mm~350mm, and replace the labeling mechanism to meet the uneven surface labeling;

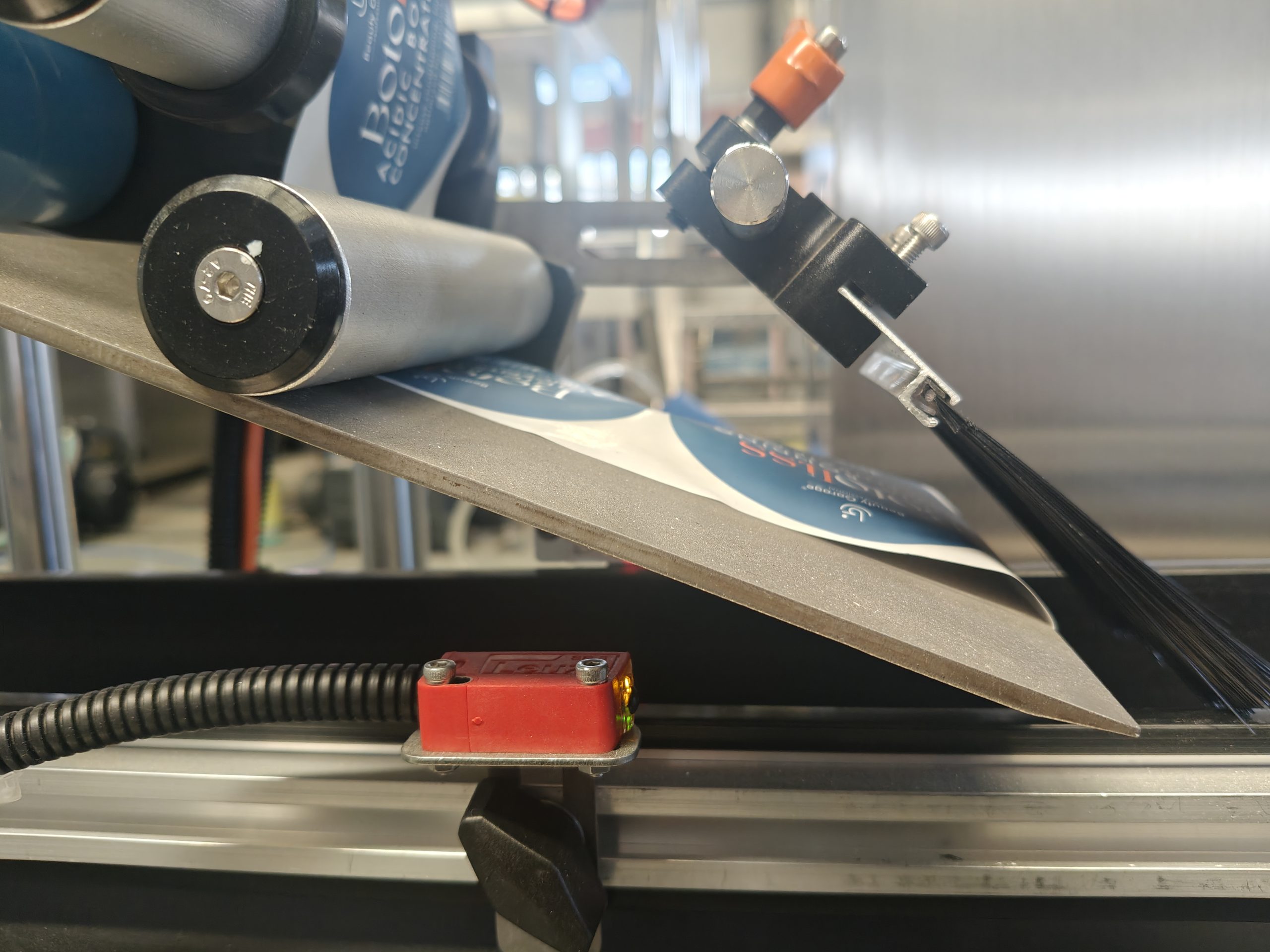

2. High precision of labeling, subdivided stepper motor or servo motor drive to send labels, accurate delivery; label belt bypass correction mechanism design, to ensure that the label does not shift left and right during the traction process; eccentric technology applied to traction mechanism, traction The label does not slip, ensuring accurate bidding;

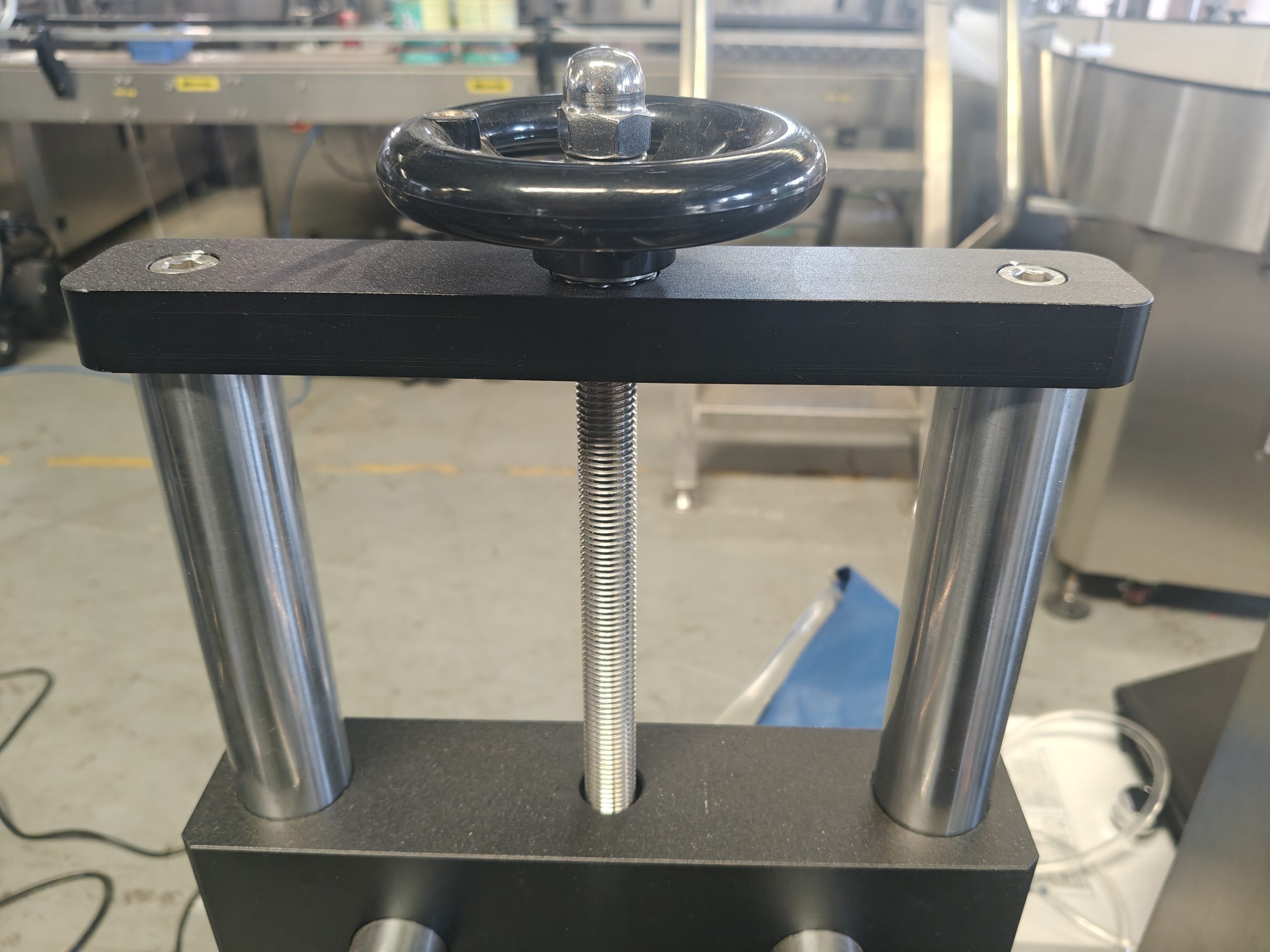

3. The adjustment seat has 6 adjustable directions and angles, the applicability is strengthened, and the conversion between different products becomes simple and time-saving;

4. Intelligent control, automatic photoelectric tracking, with no object and no labeling, no standard automatic calibration and automatic label detection to prevent leakage and label waste.

Main parameters:

1.Labeling speed: about 0-260P/min (related to product size)

2.Labeling accuracy: ±1mm (does not include product label and other errors)

3.Applicable product size: length 30-280mm; height 30-200mm;

4.Applicable label range: length 10 ~ 260mm, width 10-155mm

5.Max label supply: OD 300 or less, inner diameter 76mm

6.Use environment: 0-50 °C

7.Relative humidity: 15-85%

8.Voltage specification: AC220V 50/60Hz

9.Dimensions: about L2200*W1400*H1750mm

10.Weight: about 160Kg

11.Labeling machine label parameters (for reference only):

12.Label spacing: 2-3mm ± 0.2mm

13.Label feeding method is coil material

14.Material: It is recommended to use Glassine body paper, it should to avoid cuts , which affects the normal operation of labeling