Table of Contents

Introduction

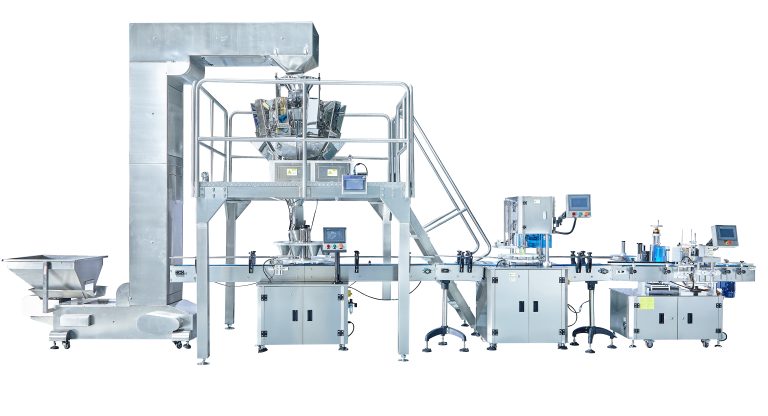

In the bustling health and wellness market, protein powder stands as a cornerstone product. From gym – goers aiming for muscle gain to individuals seeking a convenient nutritional boost, the demand for high – quality protein powder is sky – high. For manufacturers, meeting this demand while maintaining product quality is a constant challenge. Enter the automatic dual – head protein powder filling machine, a technological marvel that promises to unleash the power of precision in the filling process.

The Quest for Precision in Protein Powder Filling

Precision is not just a buzzword in protein powder filling; it’s a necessity. Consumers expect each container of protein powder to have the exact amount of product as stated on the label. Any deviation, whether it’s under – filling or over – filling, can lead to a host of problems. Under – filled containers can result in customer dissatisfaction, negative reviews, and potential legal issues. Over – filled containers, on the other hand, mean wasted product and increased costs for the manufacturer.

Traditional filling methods, such as manual scooping or basic single – head filling machines, often struggle to achieve the level of precision required in today’s market. Human error, inconsistent pouring, and mechanical limitations can all contribute to inaccurate filling levels.

How the Automatic Dual – Head Filling Machine Achieves Precision

Advanced Measurement Technology

The automatic dual – head protein powder filling machine is equipped with state – of – the – art measurement technology. It can use either volumetric or gravimetric methods to ensure precise filling. Volumetric filling measures the volume of the protein powder dispensed, while gravimetric filling measures the weight. These methods are highly accurate and can be calibrated to meet the specific requirements of different protein powder products.

Dual – Head Design for Consistency

The dual – head design of the machine is a key factor in achieving precision. Both filling heads work in harmony, dispensing the same amount of protein powder simultaneously. This not only doubles the filling speed but also ensures that each container is filled with the same quantity of product. The machine’s control system monitors and adjusts the filling process in real – time, compensating for any minor variations to maintain consistent accuracy.

High – Quality Components

The use of high – quality components in the construction of the automatic dual – head filling machine also contributes to its precision. From the conveyor belts that transport the containers to the valves and nozzles that dispense the powder, every part is designed to operate with maximum efficiency and accuracy. This reduces the risk of clogs, spills, and other issues that could affect the filling process.

Benefits of Precision Filling

Enhanced Product Quality

Precision filling directly translates to enhanced product quality. When each container has the exact amount of protein powder, consumers can trust that they are getting what they paid for. This builds brand loyalty and a positive reputation in the market.

Cost Savings

By eliminating over – filling, the automatic dual – head filling machine helps manufacturers save on product costs. Additionally, the reduction in product waste means less money spent on discarded or re – worked products.

Regulatory Compliance

In the food and supplement industry, there are strict regulations regarding product labeling and quantity. Precision filling ensures that manufacturers comply with these regulations, avoiding costly fines and legal complications.

Other Advantages of the Automatic Dual – Head Filling Machine

Increased Efficiency

As mentioned earlier, the dual – head design allows for a significant increase in filling speed. This means that manufacturers can produce more protein powder in less time, meeting market demand more effectively.

Hygiene and Safety

The machine is designed with hygiene in mind. It has a closed – loop system that minimizes the risk of contamination from external sources. The smooth surfaces and easy – to – clean components ensure that the protein powder remains pure and safe for consumption.

Versatility

The automatic dual – head filling machine can handle a variety of container sizes and shapes. Whether it’s small sachets, medium – sized bottles, or large tubs, the machine can be adjusted to accommodate different packaging requirements.

Conclusion

The automatic dual – head protein powder filling machine is a game – changer in the protein powder manufacturing industry. By unleashing the power of precision, it offers a range of benefits that can help manufacturers improve product quality, reduce costs, and stay competitive in the market. If you’re a protein powder manufacturer looking to take your production to the next level, investing in this advanced filling machine is a decision that will pay off in the long run. So, embrace the precision and efficiency of the automatic dual – head filling machine and watch your business thrive.