Automatic servo can seamer machines have become indispensable in the packaging industry. This comprehensive guide will take you through everything you need to know about them.

What Are Automatic Servo Can Seamer Machines?

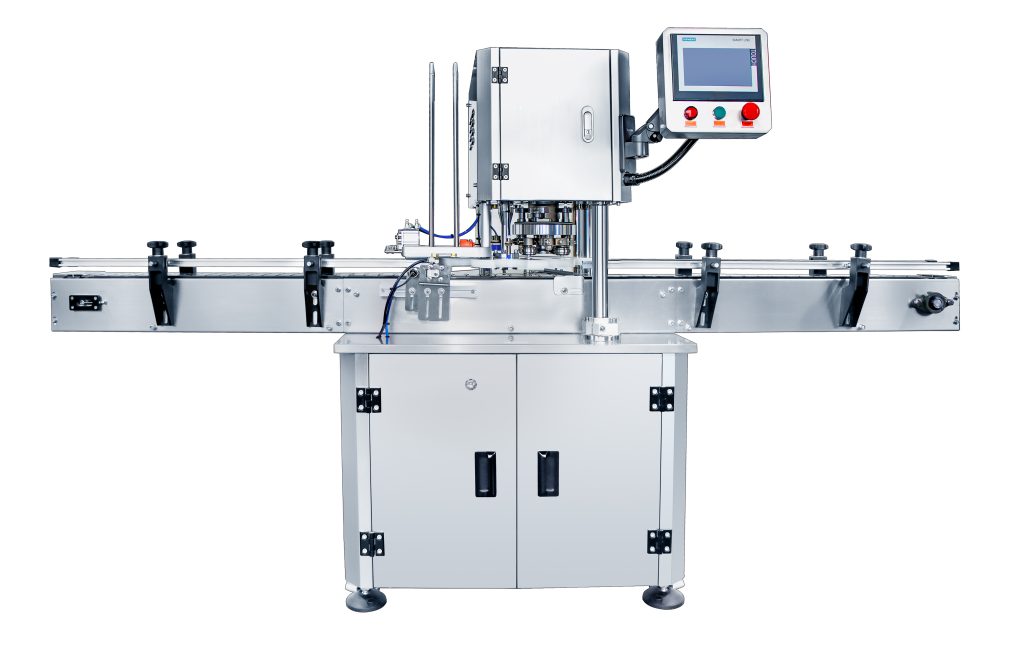

These machines are advanced devices designed to seal cans with exceptional precision and speed. They utilize servo technology to ensure accurate and consistent seaming operations.

Key Components and Features

They typically consist of a can feeding system, seaming heads or rollers, servo drives for precise control, and a control panel for adjusting parameters. Features like automatic can alignment, adjustable seaming pressure, and high-speed operation contribute to their efficiency.

How They Work

The cans are placed on a conveyor or feeding mechanism. The machine positions the can precisely, and the servo-driven seaming components apply the required force and movement to create a tight and secure seal.

Advantages of Automatic Servo Can Seamer Machines

They offer increased productivity, improved seal quality, reduced labor costs, and the ability to handle a wide range of can sizes and shapes.

Applications

These machines are widely used in industries such as food and beverage, pharmaceuticals, and chemicals for sealing cans of various products.

Maintenance and Troubleshooting

Regular maintenance is crucial to ensure optimal performance. This includes cleaning, lubricating moving parts, and checking for worn components. Common troubleshooting issues and solutions will also be covered.

Selecting the Right Automatic Servo Can Seamer Machine

Factors such as production volume, can specifications, budget, and brand reputation should be considered when making a purchase decision.

In conclusion, understanding automatic servo can seamer machines is essential for businesses looking to enhance their packaging processes and ensure the quality and safety of their products.