Table of Contents

Benefits of Using Liquid Filling Machines

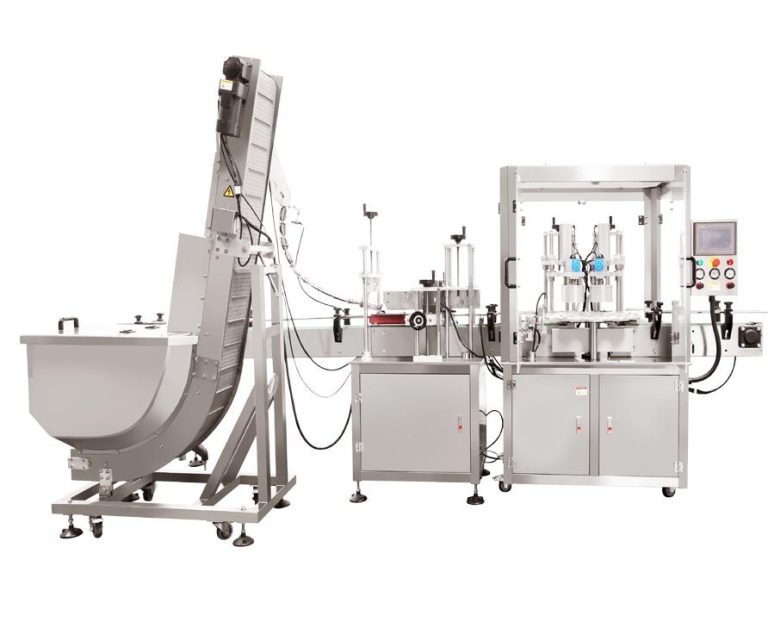

Liquid filling machines are an essential piece of equipment for many industries that deal with liquids on a daily basis. These machines are designed to accurately fill containers with liquid products, such as beverages, pharmaceuticals, chemicals, and more. The importance of liquid filling machines cannot be overstated, as they offer a wide range of benefits that can help businesses improve efficiency, accuracy, and overall productivity.

One of the key benefits of using a liquid filling machine is the ability to increase production speed. These machines are designed to fill containers quickly and accurately, which can help businesses meet high demand and increase output. By automating the filling process, businesses can reduce the time and labor required to fill containers manually, allowing employees to focus on other tasks that require their attention.

In addition to increasing production speed, liquid filling machines also offer improved accuracy. These machines are equipped with advanced technology that ensures precise filling levels, reducing the risk of underfilling or overfilling containers. This level of accuracy is crucial for industries that require precise measurements, such as pharmaceuticals or chemicals, where even a small deviation in filling levels can have serious consequences.

Another benefit of using a liquid filling machine is the ability to reduce product waste. Manual filling processes can often result in spills, leaks, and other forms of product waste, which can be costly for businesses. Liquid filling machines are designed to minimize product waste by accurately filling containers without spillage or leaks, helping businesses save money and reduce their environmental impact.

Liquid filling machines also offer improved hygiene and cleanliness. These machines are designed to meet strict hygiene standards, with easy-to-clean surfaces and materials that are resistant to corrosion and contamination. This is particularly important for industries that deal with food or pharmaceutical products, where cleanliness is paramount to ensure product safety and quality.

Furthermore, liquid filling machines can help businesses save money in the long run. While the initial investment in a liquid filling machine may seem costly, the long-term benefits far outweigh the upfront costs. By increasing production speed, improving accuracy, reducing product waste, and ensuring hygiene and cleanliness, businesses can see a significant return on investment over time.

Overall, the importance of liquid filling machines cannot be understated. These machines offer a wide range of benefits that can help businesses improve efficiency, accuracy, and productivity. From increasing production speed to reducing product waste and improving hygiene, liquid filling machines are an essential piece of equipment for industries that deal with liquids on a daily basis. Investing in a liquid filling machine can help businesses streamline their operations, save money, and ensure the quality and safety of their products.

Types of Liquid Filling Machines

Liquid filling machines are essential equipment in various industries, including pharmaceuticals, food and beverage, cosmetics, and more. These machines are designed to accurately fill containers with liquid products, ensuring consistency and efficiency in the production process. There are several types of liquid filling machines available on the market, each with its own unique features and capabilities.

One of the most common types of liquid filling machines is the piston filler. This type of machine uses a piston to draw liquid from a reservoir and dispense it into containers. Piston fillers are ideal for filling viscous liquids, such as creams, gels, and pastes, as they can handle thick substances with ease. These machines are also highly accurate, making them suitable for applications where precise filling volumes are required.

Another popular type of liquid filling machine is the gravity filler. Gravity fillers rely on the force of gravity to fill containers with liquid. As the liquid flows down from a reservoir, it is dispensed into containers placed below the filling nozzle. Gravity fillers are ideal for filling thin liquids, such as water, juice, and oil, as they can handle low-viscosity substances effectively. These machines are also easy to operate and maintain, making them a cost-effective solution for many businesses.

In addition to piston and gravity fillers, there are also rotary fillers available on the market. Rotary fillers are designed to fill multiple containers simultaneously, making them ideal for high-volume production environments. These machines use a rotating carousel to move containers through the filling process, ensuring quick and efficient filling. Rotary fillers are versatile machines that can handle a wide range of container sizes and shapes, making them suitable for a variety of applications.

For businesses looking to fill containers with a high level of precision, volumetric fillers are an excellent choice. Volumetric fillers use a predetermined volume of liquid to fill containers, ensuring consistent filling volumes every time. These machines are ideal for applications where accuracy is crucial, such as pharmaceuticals and chemicals. Volumetric fillers are also highly efficient, allowing businesses to increase their production output without sacrificing quality.

In conclusion, liquid filling machines play a crucial role in the production process for many industries. Whether you are filling containers with thick creams or thin liquids, there is a liquid filling machine available to meet your needs. From piston fillers to rotary fillers, there are a variety of options to choose from, each with its own unique features and capabilities. By investing in a high-quality liquid filling machine, businesses can improve their production efficiency, reduce waste, and ensure consistent product quality.

Factors to Consider When Choosing a Liquid Filling Machine

When it comes to packaging liquids, having the right equipment is crucial to ensure efficiency and accuracy. A liquid filling machine is an essential tool for businesses that deal with liquids on a regular basis. These machines are designed to fill containers with liquid products quickly and accurately, saving time and reducing the risk of spills or errors. However, with so many options available on the market, choosing the right liquid filling machine can be a daunting task. There are several factors to consider when selecting a liquid filling machine to ensure that it meets your specific needs and requirements.

One of the most important factors to consider when choosing a liquid filling machine is the type of liquid you will be filling. Different liquids have different viscosities, which can affect the type of filling machine that is best suited for the job. For example, thin liquids like water or juice may require a different type of filling machine than thick liquids like honey or syrup. It is important to choose a machine that is designed to handle the specific viscosity of the liquid you will be filling to ensure accurate and efficient filling.

Another important factor to consider when choosing a liquid filling machine is the speed and capacity of the machine. The speed at which the machine can fill containers will directly impact the efficiency of your production line. If you have a high-volume production line, you will need a machine that can fill containers quickly to keep up with demand. Additionally, the capacity of the machine will determine how many containers can be filled at once, which is important for businesses with large production runs.

In addition to speed and capacity, it is also important to consider the accuracy of the liquid filling machine. Accuracy is crucial when filling containers with liquid products, as even a small error can result in wasted product and lost revenue. Look for a machine that offers precise filling capabilities to ensure that each container is filled to the correct level every time.

The ease of use and maintenance of the liquid filling machine is another important factor to consider. A machine that is easy to operate and maintain will save time and reduce the risk of downtime. Look for a machine that is user-friendly and comes with clear instructions for operation and maintenance. Additionally, consider the availability of spare parts and technical support to ensure that your machine can be quickly repaired in the event of a breakdown.

Finally, consider the cost of the liquid filling machine and how it fits into your budget. While it may be tempting to choose the cheapest option available, it is important to consider the long-term costs of the machine, including maintenance and repairs. Invest in a high-quality machine that is built to last and will provide reliable performance for years to come.

In conclusion, choosing the right liquid filling machine is essential for businesses that deal with liquids on a regular basis. Consider factors such as the type of liquid being filled, speed and capacity, accuracy, ease of use and maintenance, and cost when selecting a liquid filling machine to ensure that it meets your specific needs and requirements. By taking the time to carefully evaluate these factors, you can choose a machine that will help streamline your production process and improve efficiency and accuracy in filling containers with liquid products.