It seems we can’t find what you’re looking for. Perhaps searching can help.

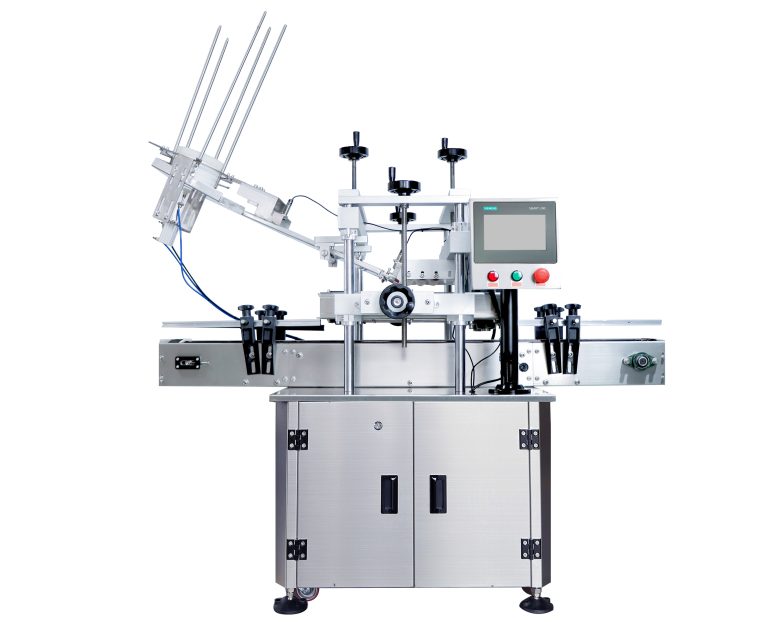

The Wafer Bottle Tape Around Sealing Machine: Enhancing Packaging Efficiency

In the world of wafer packaging, the wafer bottle tape around sealing machine is a key component in ensuring the quality and presentation of the product. This specialized machine offers several significant benefits. Firstly, it provides a secure and tight seal around the wafer bottle. This not only protects the…