コーヒー業界では、これらのフィラーがコーヒー豆の包装に正確に重要な役割を果たしています。彼らはコーヒー豆のさまざまなサイズと形状を処理することができ、毎回正確な塗りつぶしを確保します。これは、豆の品質と新鮮さを維持し、消費者に一貫したコーヒー体験を提供するのに役立ちます。

医薬品に関しては、精度と衛生の重要性が最重要です。この点でロータリー顆粒フィラーは優れています。それらは、カプセルまたは容器を薬用顆粒で正確に満たすことができ、厳格な投与量の要件と品質管理基準を順守することができます。

回転顆粒フィラーの汎用性は、さまざまな顆粒特性に適応する能力にあります。特定の薬物の細かい顆粒であろうと、食料サプリメントのより大きな顆粒であろうと、これらのフィラーは充填パラメーターを調整して最適な結果を達成できます。

-1024x683.jpg)

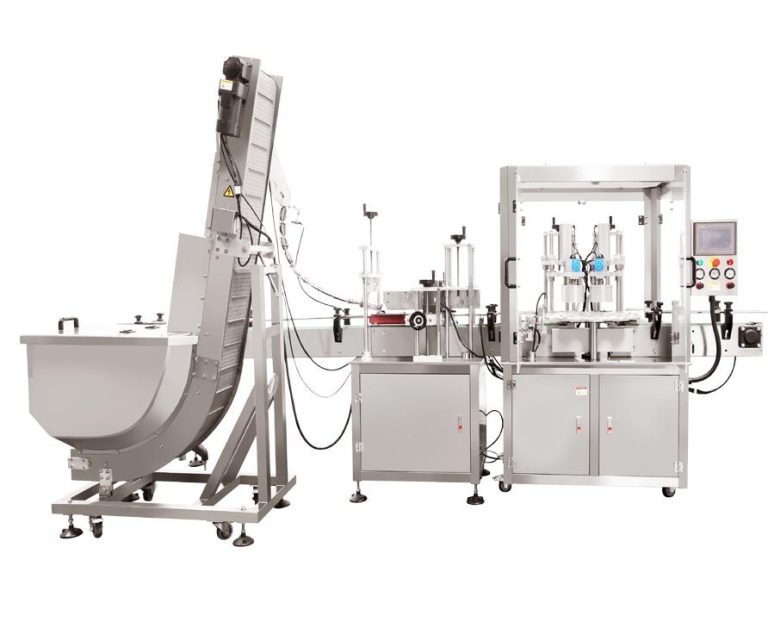

さまざまな生産量を処理するように設計されています。小規模な専門のコーヒー生産者から大規模な医薬品製造施設まで、ロータリーグラニュールフィラーは、特定のニーズを満たすために上下にスケーリングできます。

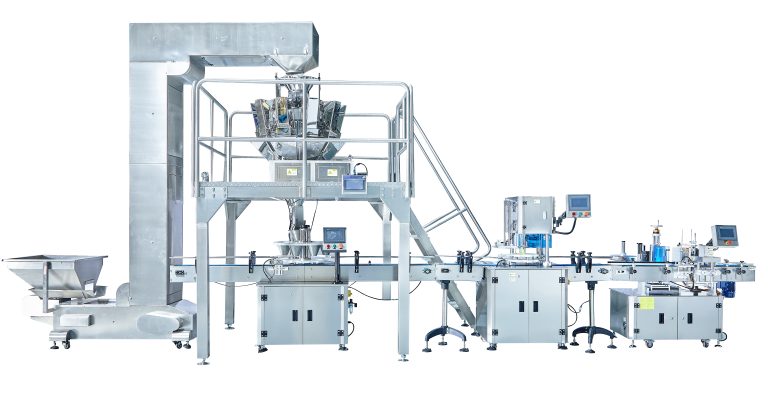

さらに、これらのフィラーには、多くの場合、充填プロセスの正確な監視と調整を可能にする高度な制御システムが付属しています。これにより、一貫した品質が保証され、エラーの可能性が低下します。

結論として、 回転顆粒フィラー‘コーヒー豆から医薬品まで、多様な製品を扱う能力は、驚くべき汎用性を示しています。それらの精度、適応性、およびスケーラビリティにより、それらは複数の業界で不可欠なツールになり、効率的で品質主導の生産プロセスに貢献しています。