Table of Contents

Benefits of Using a Fully Automatic Almond Powder Plastic Jar Packaging Line

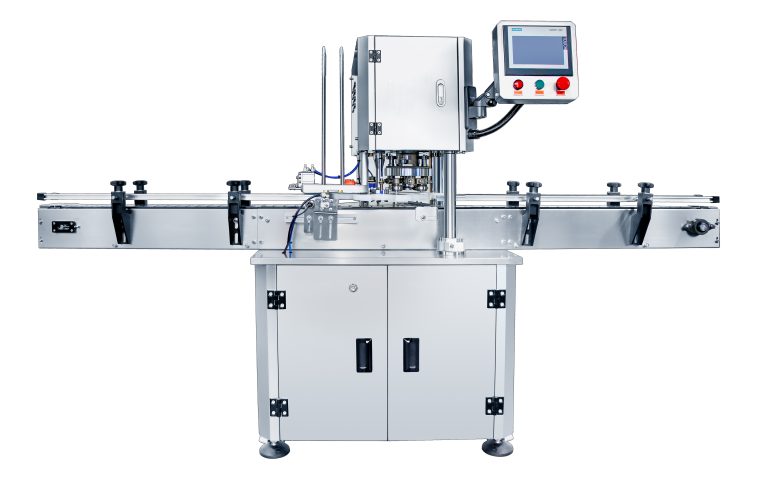

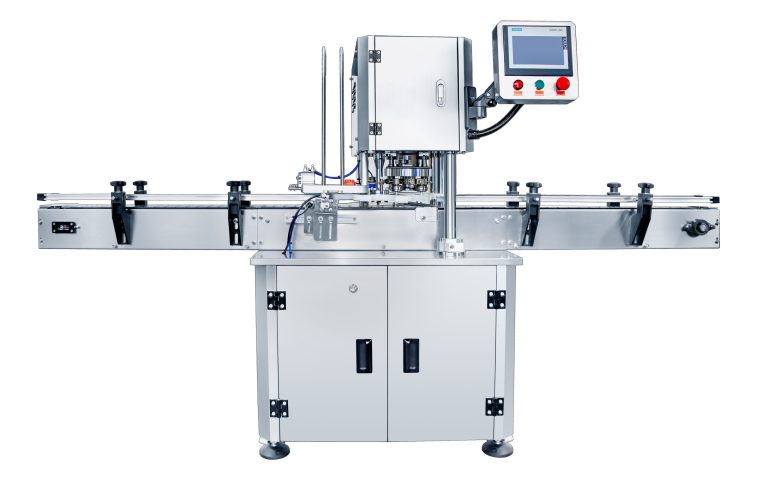

In the world of food packaging, efficiency and precision are key factors in ensuring the quality and safety of products. One of the most popular packaging options for dry food products like almond powder is plastic jars. These jars provide a secure and airtight seal, keeping the product fresh and free from contaminants. To streamline the packaging process and increase productivity, many companies are turning to fully automatic almond powder plastic jar packaging lines.

One of the main benefits of using a fully automatic packaging line is the speed at which it can package products. With automated machinery handling the filling, capping, and labeling processes, companies can significantly increase their output compared to manual packaging methods. This not only saves time but also reduces labor costs, making the production process more cost-effective in the long run.

Another advantage of a fully automatic packaging line is the consistency and accuracy it provides. Each jar is filled with the exact amount of almond powder, ensuring that every product meets the same quality standards. This level of precision is crucial in maintaining customer satisfaction and building a strong reputation for the brand.

Furthermore, fully automatic packaging lines are equipped with advanced technology that can detect and reject any defective jars or products. This helps to minimize waste and ensures that only high-quality products make it to the market. By reducing the risk of contamination or errors in packaging, companies can uphold their commitment to delivering safe and reliable products to consumers.

In addition to efficiency and accuracy, fully automatic packaging lines also offer flexibility in terms of customization. Companies can easily adjust the settings of the machinery to accommodate different jar sizes, labeling requirements, or packaging designs. This versatility allows businesses to adapt to changing market demands and stay ahead of the competition.

Moreover, fully automatic packaging lines are designed to meet strict hygiene and safety standards. The machinery is made from durable materials that are easy to clean and sanitize, reducing the risk of cross-contamination. This is especially important when packaging food products like almond powder, where maintaining cleanliness is essential to prevent spoilage or contamination.

Overall, investing in a fully automatic almond powder plastic jar packaging line can bring numerous benefits to a company. From increased productivity and cost savings to improved quality control and flexibility, automated packaging lines offer a comprehensive solution for streamlining the production process. By embracing this technology, companies can enhance their efficiency, reduce waste, and ultimately deliver a superior product to consumers.

How to Optimize Efficiency and Productivity with a Fully Automatic Almond Powder Plastic Jar Packaging Line

In today’s fast-paced world, efficiency and productivity are key factors in the success of any business. When it comes to packaging lines, having a fully automatic system can greatly optimize these aspects. One such system that is gaining popularity in the food industry is the fully automatic almond powder plastic jar packaging line.

This innovative packaging line is designed to streamline the packaging process for almond powder in plastic jars. By automating the entire process, from filling the jars to sealing them, this system can significantly increase efficiency and productivity. In this article, we will explore how businesses can benefit from implementing a fully automatic almond powder plastic jar packaging line.

One of the main advantages of a fully automatic packaging line is its ability to reduce labor costs. With a fully automated system, fewer workers are needed to operate the line, as most of the tasks are performed by machines. This not only saves money on labor costs but also reduces the risk of human error, resulting in a more consistent and reliable packaging process.

Another benefit of a fully automatic packaging line is its ability to increase production speed. By automating the packaging process, the line can run at a much faster pace than a manual system. This means that businesses can package more almond powder in a shorter amount of time, leading to increased productivity and higher output.

In addition to labor cost savings and increased production speed, a fully automatic packaging line also offers improved product quality. With precise and consistent packaging, businesses can ensure that each jar of almond powder is filled to the correct weight and sealed properly. This not only enhances the overall quality of the product but also reduces the risk of product recalls due to packaging errors.

Furthermore, a fully automatic packaging line can help businesses meet the growing demand for almond powder products. With the ability to package more products in less time, businesses can easily scale up their production to meet market demand. This flexibility is crucial for businesses looking to expand their product offerings and reach new customers.

To fully optimize efficiency and productivity with a fully automatic almond powder plastic jar packaging line, businesses should also consider integrating other technologies, such as barcode scanning and tracking systems. These technologies can help businesses track the movement of products along the packaging line, monitor inventory levels, and ensure timely delivery to customers.

In conclusion, a fully automatic almond powder plastic jar packaging line is a valuable investment for businesses looking to optimize efficiency and productivity in their packaging process. By reducing labor costs, increasing production speed, improving product quality, and meeting market demand, businesses can benefit greatly from implementing this innovative packaging solution. With the right technology and systems in place, businesses can streamline their packaging process and stay ahead of the competition in today’s fast-paced market.