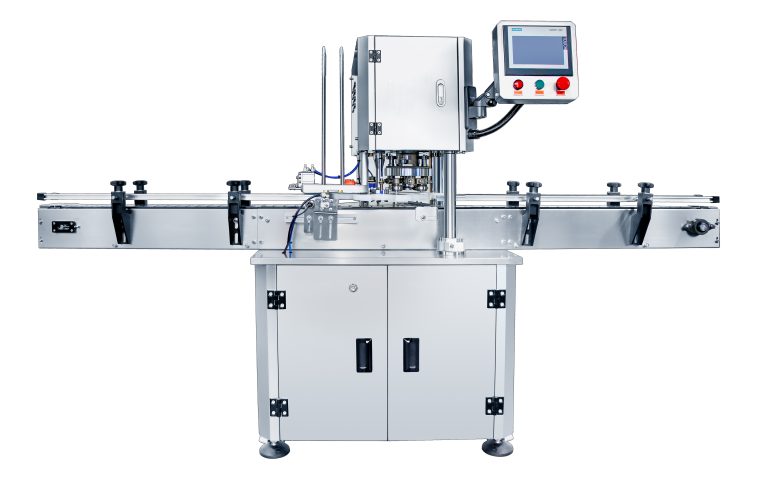

In the realm of packaging, the automatic lid cap top sticker labeling machine emerges as a highly valuable and efficient tool.

This machine is specifically designed to accurately and quickly apply stickers or labels to the top of lid caps. By automating this process, it significantly reduces the time and effort required compared to manual labeling methods.

One of its key advantages is its precision. The machine precisely positions the labels on the lid caps, ensuring that they are placed in the correct orientation and at the exact location. This results in a professional and consistent look for the packaged products.

With its high-speed operation, the automatic lid cap top sticker labeling machine can handle a large volume of lid caps in a short period. This makes it ideal for mass production lines where speed and efficiency are crucial.

The machine is also quite flexible, capable of accommodating different sizes and shapes of lid caps. It can easily adapt to various packaging requirements, making it a versatile addition to any packaging facility.

Furthermore, it often comes with advanced control systems that allow for easy adjustment and calibration. Operators can fine-tune the machine according to the specific label and lid cap specifications, ensuring optimal performance.

In terms of quality control, the machine is equipped with sensors and monitoring mechanisms. It can detect any mislabeling or improper placement of labels, enabling quick identification and correction of errors, thereby reducing the number of defective packages.

Overall, the automatic lid cap top sticker labeling machine plays a vital role in modern packaging operations, helping to boost productivity, improve packaging quality, and meet the demands of high-volume production.

Stay tuned to our blogs for more insights into the latest developments in packaging machinery.

-768x622.jpg)