It seems we can’t find what you’re looking for. Perhaps searching can help.

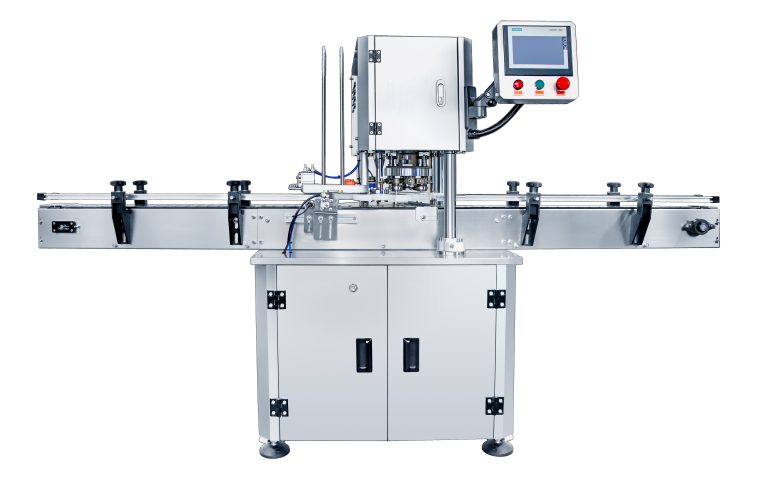

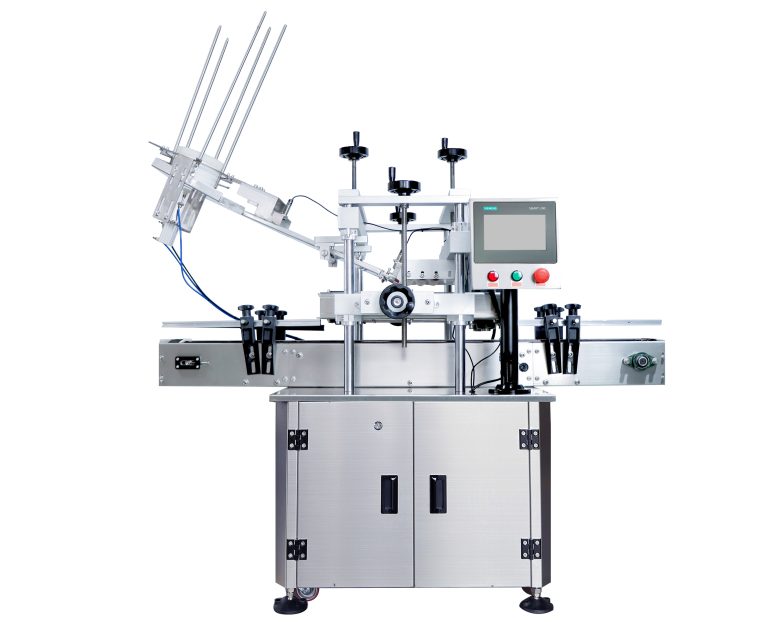

Automatic tin can labeling equipment

Benefits of Using Automatic Tin Can Labeling Equipment Automatic tin can labeling equipment is a valuable tool for businesses looking to streamline their labeling process and increase efficiency. This type of equipment offers a range of benefits that can help companies save time and money while improving the overall quality…